What is Electromechanical Assembly?

Share Article:

Electromechanical assembly combines electrical and mechanical components into a single system that powers or controls a device. These assemblies are used in everything from vehicles and power systems to industrial machines and electronics.

A well-built electromechanical assembly improves performance, reduces complexity, and helps ensure long-term reliability.

Understanding Electromechanical Assemblies

An electromechanical assembly is a complete unit made up of interconnected electrical and mechanical parts. This can include wires, circuit boards, switches, motors, and structural elements like brackets or housings.

Each component works together to perform a specific function, whether it's delivering power, enabling motion, or supporting communication between systems. These assemblies are built to precise specifications and often customized to fit the requirements of a larger machine or product.

Core Components of Electromechanical Assemblies

Electromechanical assemblies are made up of several interconnected systems that work together to deliver power, motion, or control. While designs vary by application, most include a mix of power sources, wiring, and mechanical hardware.

The following components are common in most assemblies and play a critical role in the overall function.

Power Supply Integration

Every electromechanical assembly relies on a stable source of power. Integrated power systems deliver the correct voltage and current to each component while protecting against surges and overloads.

These setups often include circuit breakers, transformers, and voltage regulators to support consistent operation and prevent electrical faults.

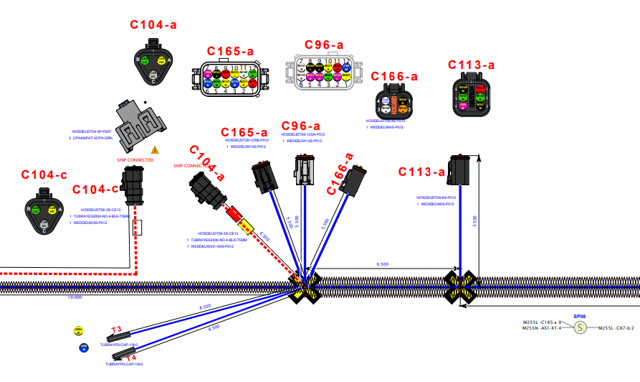

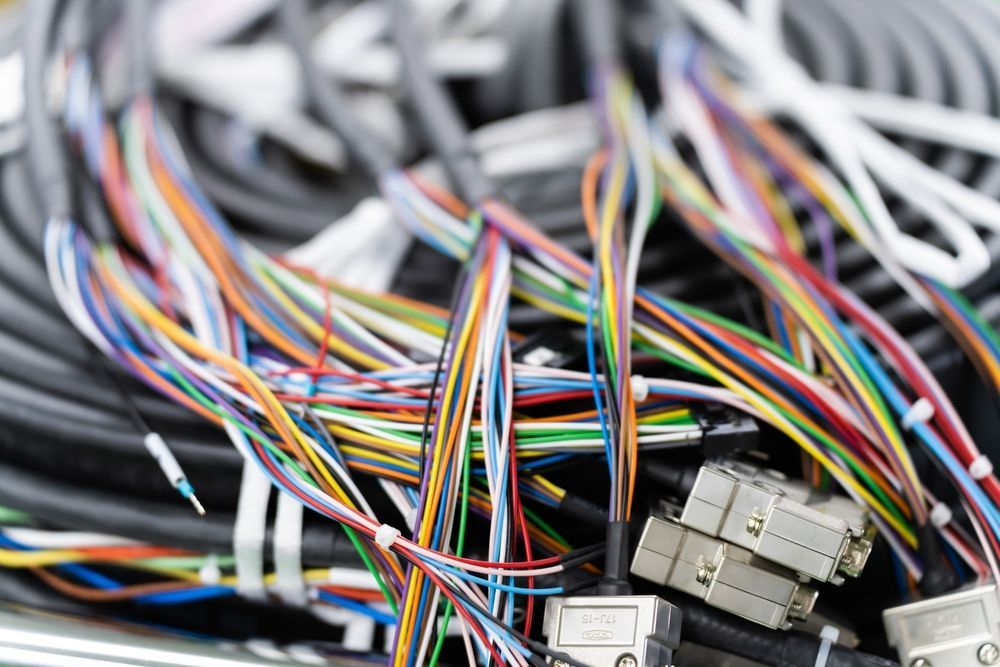

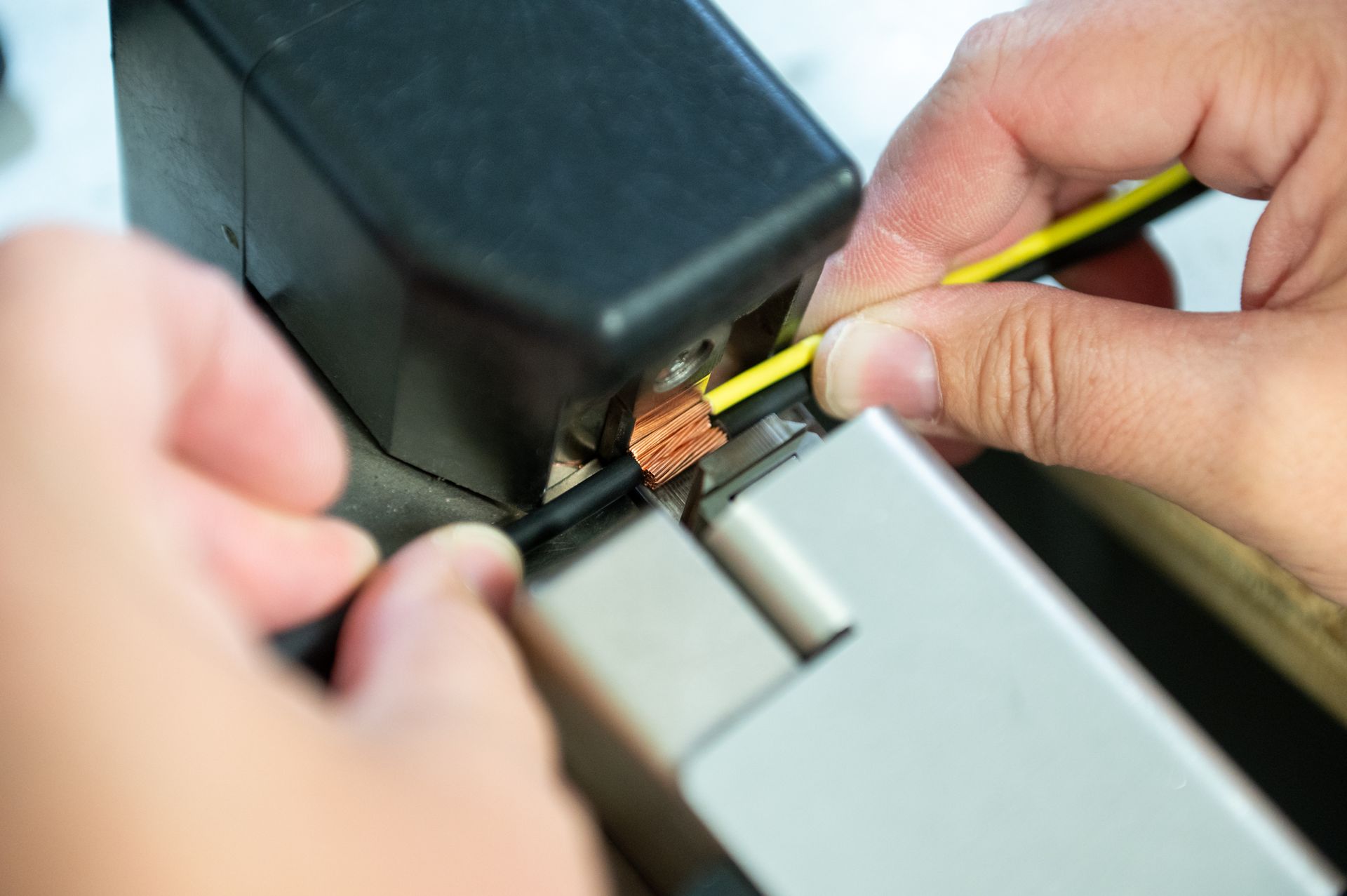

Custom Cable Assemblies

Custom cable assemblies route power and signals throughout the system. These assemblies are built to match the exact length, connector type, and configuration required for the application.

Proper cable design supports clean installation, reduces clutter, and helps prevent connection issues. By tailoring each assembly to the system, performance and reliability are both improved.

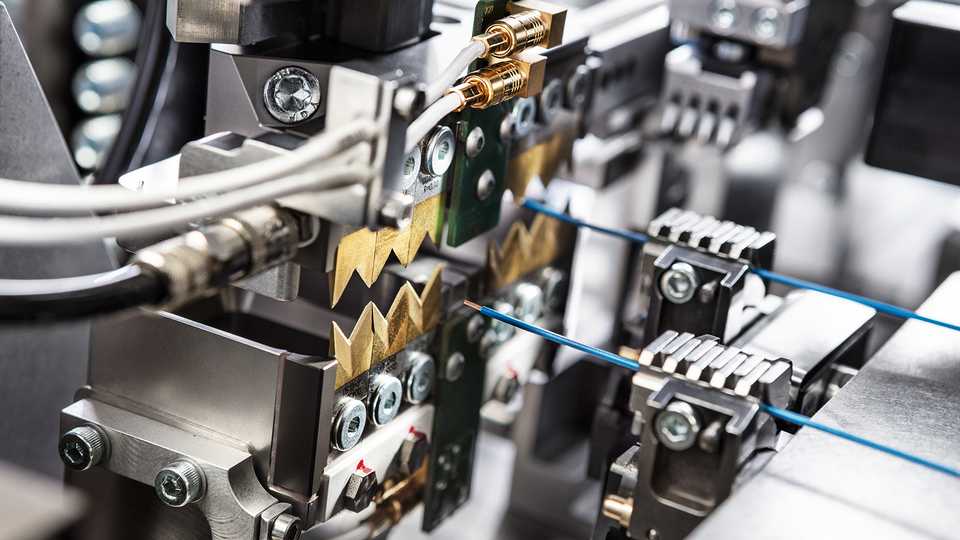

Precision Wire Harnesses

Wire harnesses group multiple wires into a single, organized structure. This arrangement helps prevent tangling, reduces wear, and keeps connections clearly defined.

Accurate layout and labeling are especially important in compact or complex systems. A properly assembled harness makes installation easier and maintains clean, reliable performance over time.

Where Electromechanical Assemblies Are Used

Electromechanical assemblies enable complex systems to manage power, movement, and control with accuracy. They are a key part of the equipment that operates under demanding conditions and must deliver consistent performance.

Automotive and Specialty Vehicles

Electromechanical assemblies manage key systems in today’s vehicles, including power control, lighting, diagnostics, and onboard electronics. In fire trucks, service fleets, and other specialty platforms, they enable essential functions under demanding conditions.

Heavy Equipment and Industrial Machinery

In industrial environments, electromechanical assemblies handle high-power loads, automation controls, and rugged mechanical interfaces. These systems must operate reliably under extreme conditions, including vibration, heat, and constant use.

Well-planned assemblies contribute to machine uptime, safety, and overall system efficiency.

Technology and Electronics

Many advanced systems rely on electromechanical assemblies to manage power, control interfaces, and coordinate motion. These solutions are used in medical devices, lab instruments, industrial controls, and high-precision electronics.

Power Generation

Power generation systems depend on electromechanical assemblies to manage distribution, monitoring, and control. These units often link sensors, breakers, and interface panels within generators or backup systems.

Durability and electrical integrity are especially important in this setting, where consistent output and fast response are critical.

Build Your Electromechanical Solution with Us

At Kato Cable, we design and assemble electromechanical systems tailored to application requirements. Our team works closely with OEMs to provide solutions that combine precision, reliability, and efficiency.

Bring us your next project, new designs, upgrades, or replacements, and we’ll help take it from concept to production with confidence.