GXL vs TXL Wire: Key Differences & Best Uses

Share Article:

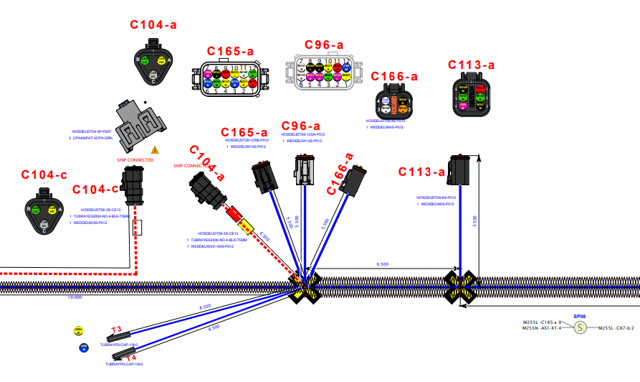

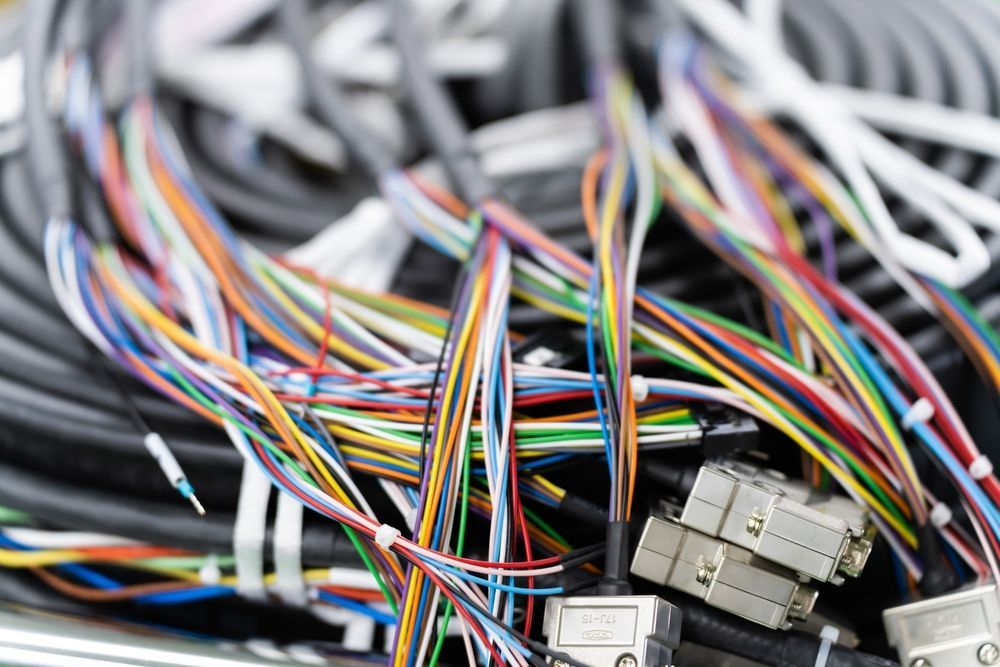

Automotive and industrial electrical systems depend on consistent performance under pressure. The wiring inside those systems plays a direct role in delivering that reliability. Two of the most common types used in harnesses and assemblies are GXL and TXL wire. Though similar in some ways, they perform differently under specific conditions. Knowing where each fits best can help OEMs make more informed decisions for their equipment.

Understanding TXL Wire

TXL wire is a lightweight, thin-wall automotive wire made with cross-linked polyethylene insulation. It's commonly used in vehicle electrical systems where space and weight are limited. The thinner insulation helps streamline harness design without sacrificing performance under high heat.

Key Conductivity Traits of TXL Wire

TXL wire typically uses stranded bare copper conductors, which offer strong electrical conductivity and flexibility. The copper strands allow the wire to carry current efficiently while handling vibration and movement common in automotive environments.

The XLPE insulation provides low dielectric loss, meaning less energy is lost as heat during transmission. This trait helps maintain voltage stability across circuits, even when the wire is routed through tight areas or exposed to thermal cycling.

TXL’s consistent conductivity under load makes it suitable for powering sensors, control modules, and lighting systems that rely on stable electrical performance.

TXL Wire’s Operating Specs and Strengths

TXL wire is rated for temperatures up to 125°C and voltages up to 50V. It performs well in under-the-hood environments where both heat and electrical load are common. The cross-linked polyethylene insulation resists abrasion, chemicals, and moisture. These properties help extend wire life across a range of operating conditions.

The thin-wall construction cuts weight and saves space in wire harnesses. This allows for tighter bundling and cleaner routing paths, which is especially valuable in compact vehicle platforms and equipment enclosures.

TXL wire also holds its shape under thermal stress. The cross-linked insulation keeps its form and flexibility over time, even after prolonged exposure to elevated temperatures.

Understanding GXL Wire

GXL wire is another automotive-grade wire featuring cross-linked polyethylene insulation. It’s known for having a medium-thickness wall that balances durability and flexibility. GXL is widely used in engine compartments, chassis wiring, and other areas exposed to heat, oil, and physical wear.

Compared to TXL, GXL wire has slightly thicker insulation, which offers added mechanical protection. It's still flexible enough for most routing needs, but it leans more toward durability than space savings.

Key Conductivity Traits of GXL Wire

GXL wire uses stranded bare copper conductors similar to TXL, delivering solid electrical conductivity for high-reliability circuits. The copper core handles current consistently, making it suitable for powering pumps, fans, ignition systems, and lighting assemblies.

The XLPE insulation minimizes dielectric loss and supports stable voltage transmission across long runs or in areas exposed to vibration. While the conductivity is nearly identical to TXL, the added insulation thickness provides a slight advantage in environments where physical abrasion or exposure to fluids is more likely.

GXL maintains conductivity even when exposed to sharp bends or fluctuating temperatures, making it dependable in both static and moving assemblies.

GXL Wire’s Operating Specs and Strengths

GXL wire is rated for continuous operation up to 125°C and up to 50V, meeting the same SAE J1128 standard as TXL. Its thicker insulation offers increased abrasion resistance and better protection in high-vibration areas.

The insulation also holds up well against fuel, oil, brake fluid, and other automotive chemicals. This makes GXL a strong fit for wiring routed through engine compartments or areas near hydraulic systems.

While slightly less flexible than TXL, GXL wire is still easy to route and install in most applications. The added wall thickness trades a small amount of bendability for a longer service life in rugged environments.

GXL vs TXL: A Head-to-Head Comparison

GXL and TXL wires serve many of the same functions but differ in construction, performance, and handling. These differences affect how each one fits into a specific design or environment.

Flexibility & Size Efficiency

TXL wire is more flexible due to its thinner insulation and smaller outer diameter. This makes it easier to bend, twist, and route in compact enclosures. GXL is slightly stiffer but still manageable for most installations.

Temperature & Voltage Ratings

Both wires are rated for up to 125°C and 50V. From a thermal and electrical standpoint, they perform similarly under standard automotive and industrial operating conditions.

Insulation & Durability Differences

GXL features a thicker insulation wall, offering more protection against abrasion and exposure to fluids. TXL uses a thinner wall, which reduces weight and bulk in the harness. For routing through tight spaces, TXL is easier to manage. For higher wear zones, GXL offers better shielding.

Best Use Cases for GXL and TXL Wires

GXL is often selected for power circuits and exposed routing where rugged insulation adds reliability. TXL is used more in signal circuits and multi-branch harnesses where space constraints and handling flexibility matter more.

Choosing Based on Environment and Equipment

Equipment layout and exposure should guide the wire choice. In open-frame designs or compartments near heat and fluid sources, GXL offers better resistance to wear. In sealed assemblies or interior routing paths, TXL simplifies installation and allows for tighter bundling.

The amount of movement or vibration in the system also plays a role. For fixed paths with more abrasion risk, GXL provides a safety margin. For confined spaces where wiring needs to bend and flex around components, TXL is easier to manage.

Cost vs. Performance Considerations

TXL wire typically costs less due to its thinner insulation and lighter construction. For high-volume builds where space and cost are priorities, it offers strong value. GXL wire may carry a slightly higher material cost, but that’s often offset by longer service life in demanding environments.

Choosing between them often comes down to total installed performance. A lower-cost wire that’s easier to route may save labor hours. A more durable wire may reduce maintenance or downtime later.

Partner With Kato Cable for Custom Wire Harnesses

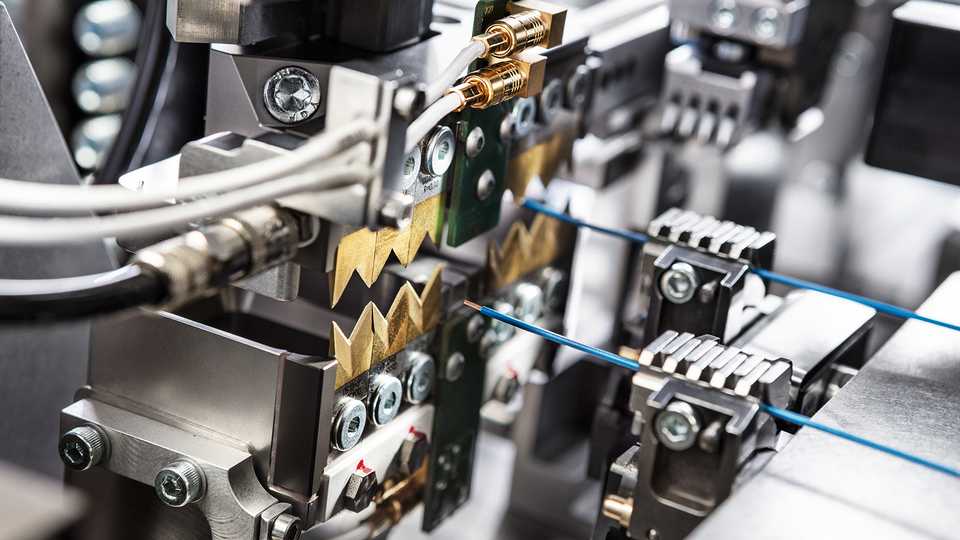

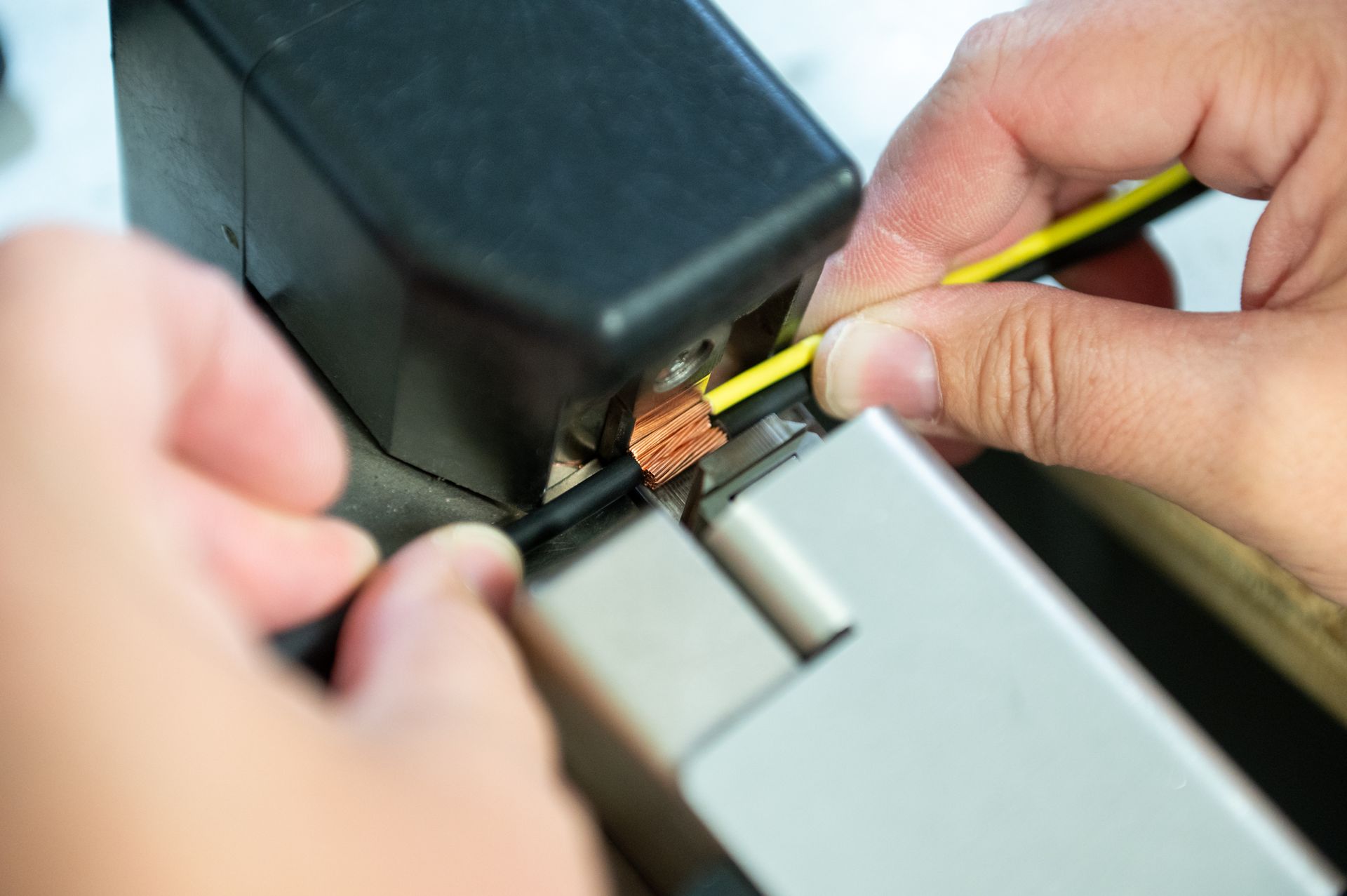

Kato Cable designs and manufactures wire harnesses built for performance, longevity, and efficient integration. We collaborate directly with OEMs to evaluate options like GXL and TXL wire based on electrical load, routing constraints, and environmental exposure.

Our process covers everything from initial design through production, using consistent quality checks and proven assembly methods. These harnesses are engineered to perform reliably under heat, vibration, and fluid contact, all while meeting the exact fit and function your systems require.

Request a Quote to start a conversation, or connect with us on LinkedIn and Facebook to see how we work with OEMs across industries.