Control Panel Wiring: Connection and Routing Tips

Share Article:

OEMs rely on control panels to manage power, signal flow, and system automation across their equipment. These panels serve as central command units, connecting switches, relays, sensors, and circuit protection devices into one organized interface. Wiring brings structure to that system. Every connection must support electrical performance, environmental demands, and maintenance needs. Getting the wiring right at the start saves time, improves uptime, and keeps assemblies field-ready.

What Is Control Panel Wiring?

Control panel wiring connects the electrical and electronic components that manage equipment functions. It includes every conductor inside the enclosure, from power supply lines and control circuits to signal cables and communication links. Each wire plays a role in activating relays, energizing motors, reading sensors, or triggering alarms.

The layout must match the demands of the application. Voltage ratings, current loads, environmental factors, and safety requirements all influence how the wiring is selected and installed. Organized routing prevents interference, while proper termination maintains conductivity and prevents failure. A well-wired panel delivers consistency, clarity, and control in the field.

Wiring Standards Every OEM Should Know

Standardization helps OEMs build safer, more reliable panels. It also simplifies inspection, maintenance, and troubleshooting. These key standards guide how wires are selected, routed, and labeled:

UL 508A

Covers the construction of industrial control panels for North American markets. Specifies wire types, spacing, overcurrent protection, and labeling requirements.

NFPA 79

Applies to electrical wiring in industrial machinery. Sets rules for conductor sizing, color coding, grounding, and routing inside equipment.

IEC 60204-1

Focuses on electrical safety in machinery for international markets. Details insulation types, wire identification, and system protection.

NEC (National Electrical Code)

Establishes safe practices for wiring, grounding, and circuit protection. Often used alongside UL and NFPA standards.

Color Coding Conventions

Follow recognized color systems for conductors, such as black for AC power, red for DC power, blue for control wiring, and green/yellow for ground.

Meeting these standards helps panels pass inspections and operate reliably in the field. It also reduces downtime caused by wiring faults or mislabeling.

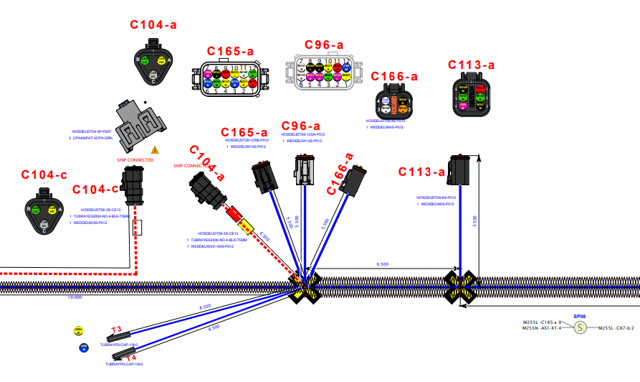

Smart Layout Tips for Panel Designers

Tangled wiring and tight clearances slow down both assembly and troubleshooting. Clean layout starts long before the first component is mounted. These practices help designers stay organized and efficient throughout the build:

Group Components Logically

Keep relays, circuit breakers, PLCs, and motor starters arranged by function. This improves readability and supports faster maintenance.

Follow a Left-to-Right Flow

Start with incoming power on the left and move toward control and output devices on the right. Aligning physical layout with electrical schematics speeds up wire routing and testing.

Maintain Clearances

Allow room between components for airflow, wire routing, and tool access. Crowded panels increase the risk of connection errors and heat buildup.

Plan for Wire Ducts Early

Select duct sizes based on wire counts and bending radius. Planning this after the layout leads to congestion and lost time.

Reserve Room for Expansion

Unused DIN rail and spare terminals give room for future I/O or system modifications without a full redesign

Keep Labels Visible

Position devices so that terminal markings and labels remain readable after wiring.

Wire Routing Best Practices

Wiring should follow a layout that’s easy to trace and built to handle real-world use. Routing decisions affect airflow, durability, and how quickly a technician can make changes.

Keep power lines away from signal conductors

Separate paths help prevent noise interference and protect communication circuits from electrical disturbances.

Use direct, parallel runs

Straight lines look cleaner and make it easier to follow circuits during inspection. Avoid zigzags and overlapping routes.

Allow for smooth bends

Sharp turns stress the insulation and terminals. Larger conductors need wider curves to stay intact.

Fasten wiring along its path

Tied-down wires are less likely to move, wear, or loosen during machine operation or transport.

Leave breathing room in ductwork

Crowded channels slow down repairs and increase heat inside the enclosure.

Match routes to connection points

Bring wires into terminals cleanly, without twisting or unnecessary turns.

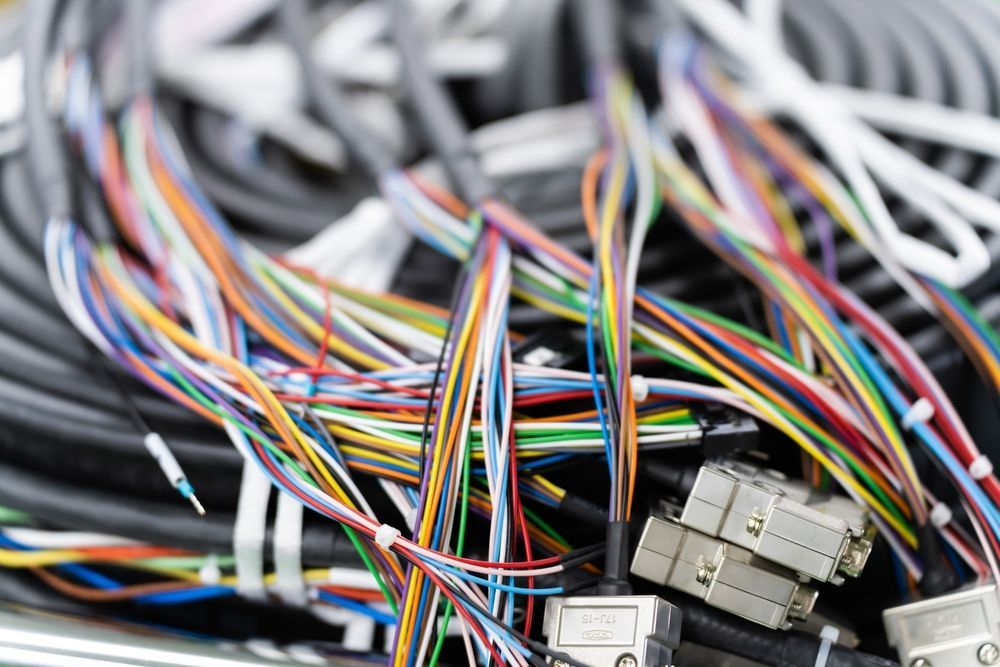

Choosing the Right Wire Types & Sizes

The wrong wire can cause performance problems that aren't always easy to trace. Choosing the right type starts with knowing the current the circuit will carry and how far that current needs to travel. Length, load, and layout all affect what gauge is appropriate.

Insulation matters just as much. Some wires are made for high heat. Others hold up better around moisture, oil, or vibration. The conditions inside the panel and around the equipment help determine what materials make sense.

Stranded wire is often the better choice for control panels. It's easier to route, handles movement better, and fits securely in most terminal types. Solid wire may work for short runs, but is more likely to fatigue over time.

Voltage ratings need to match or exceed what is present in the circuit. Anything less can break down under normal use. Using a consistent color scheme for each function, such as power, control, and ground, makes the panel easier to read and safer to work on.

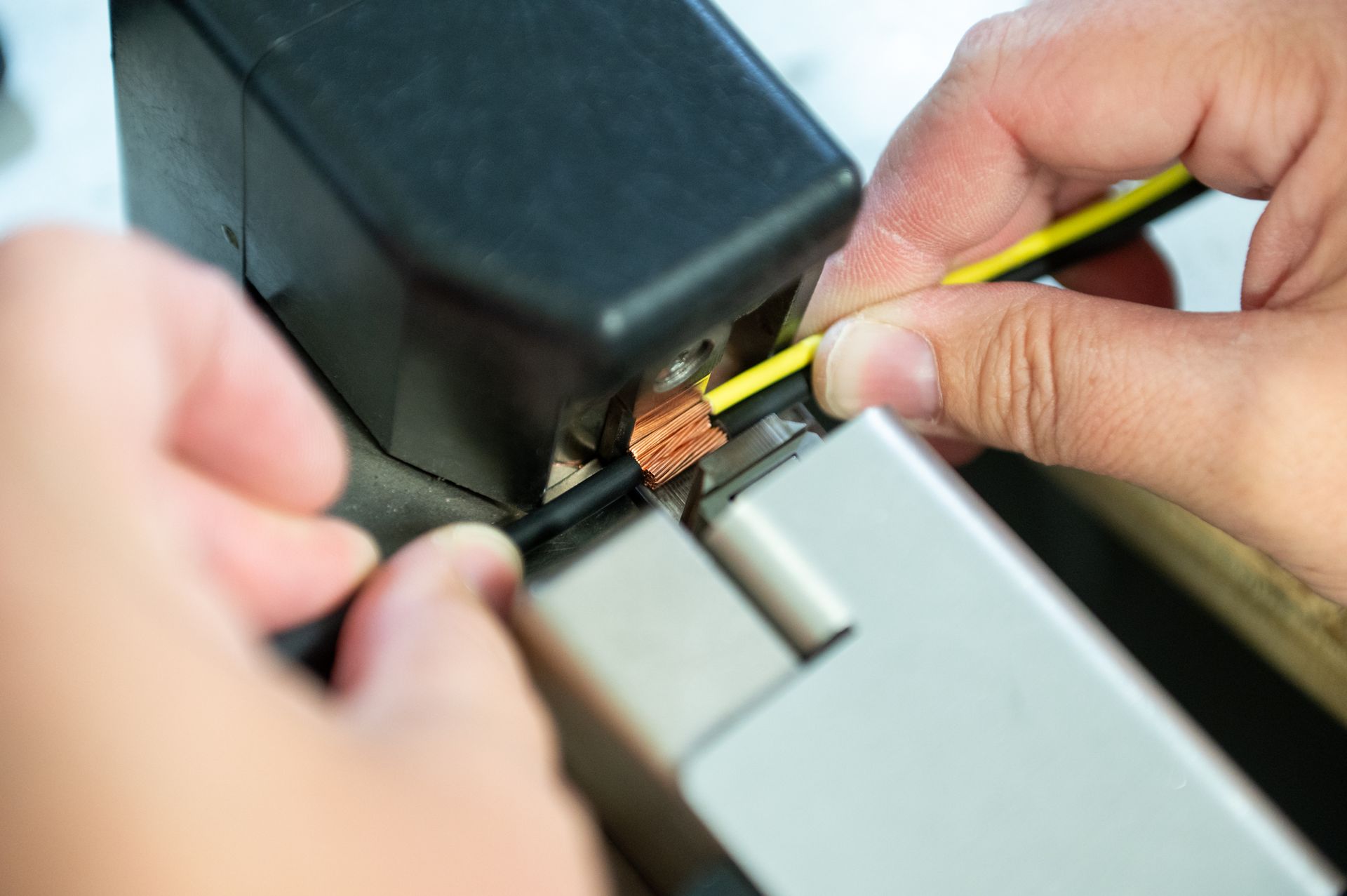

Termination, Ferrules & Labeling Tips

Wiring isn’t finished until the ends are secure and labeled. A clean cut and proper strip length make the difference between a strong connection and one that fails under load. Jagged strands or damaged insulation lead to weak spots.

Ferrules help stranded wire stay intact inside screw or spring-clamp terminals. They improve pressure distribution and make maintenance easier. Pre-insulated ferrules also reduce wear during service.

Labeling must be permanent and easy to read. Each wire should match the schematic and stay visible after routing. Placing labels too close to terminals or behind duct covers slows down work.

Getting this right saves time and avoids confusion during installation, repair, or upgrades.

Avoid These Common Wiring Mistakes

- Improper terminal torque

Over-tightening damages components. Under-tightening allows movement and heat buildup. - Mismatched connector types

Using the wrong terminal or skipping sleeves results in poor contact. - Relying on memory for the wire ID

Faded or missing labels cause errors during service. - Running conductors across ventilation paths

Blocking airflow raises internal temperatures. - Leaving sharp wire ends

Rough cuts or splayed strands can cause shorts or pierce insulation. - Ignoring panel motion or vibration

Panels on mobile equipment need routing and anchoring that hold up under motion.

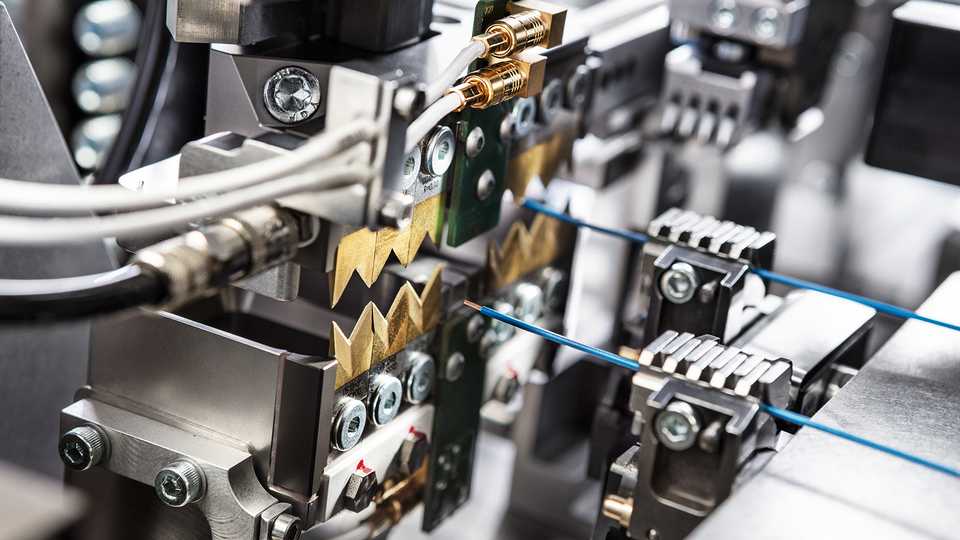

Tools That Make Wiring More Efficient

- Automatic wire strippers

Speed up prep and reduce the risk of nicking conductors. - Crimping tools with ratcheting action

Deliver consistent pressure and better terminations for ferrules or terminals. - Label printers

Create durable, readable markers faster than handwriting and reduce labeling errors. - Cable tie guns

Apply uniform tension to zip ties and trim excess in one motion for a cleaner finish. - Wire duct cutters

Make clean, fast cuts for routing channels without cracking or rough edges. - Digital multimeters with continuity mode

Quickly verify circuit paths and terminal assignments during the final check.

Designing for Maintenance & Scalability

Flexible panels make future changes easier. Extra terminals, space in wire ducts, and consistent labeling allow for quick updates without a full rebuild.

Mounting parts on DIN rail simplifies replacement. Components snap in or out without modifying the enclosure.

Key parts like relays and fuses should be easy to reach. Removable backplates and swing-out sections help with faster service.

Clear schematics that match the final build reduce errors and keep maintenance efficient.

Why OEMs Choose Kato for Control Panel Assembly

Kato Cable delivers control panels built for reliability, clean layout, and field-ready performance. Each build reflects precise coordination and a focus on what OEMs need to keep operations moving.

Customers count on fast response times, consistent results, and clear communication at every step.

Looking for a dependable partner in control panel assembly? Request a quote or connect with us on LinkedIn.