How Komax Zeta Improves Wire Processing Efficiency

Share Article:

Modern wire harness production requires speed, accuracy, and flexibility. As product designs become more complex, manual processing can slow output and introduce inconsistency. The Komax Zeta is designed to automate key stages of wire preparation, from cutting and crimping to labeling and sorting. It brings greater efficiency to

cable assembly operations and handles high-mix, high-volume production without sacrificing quality.

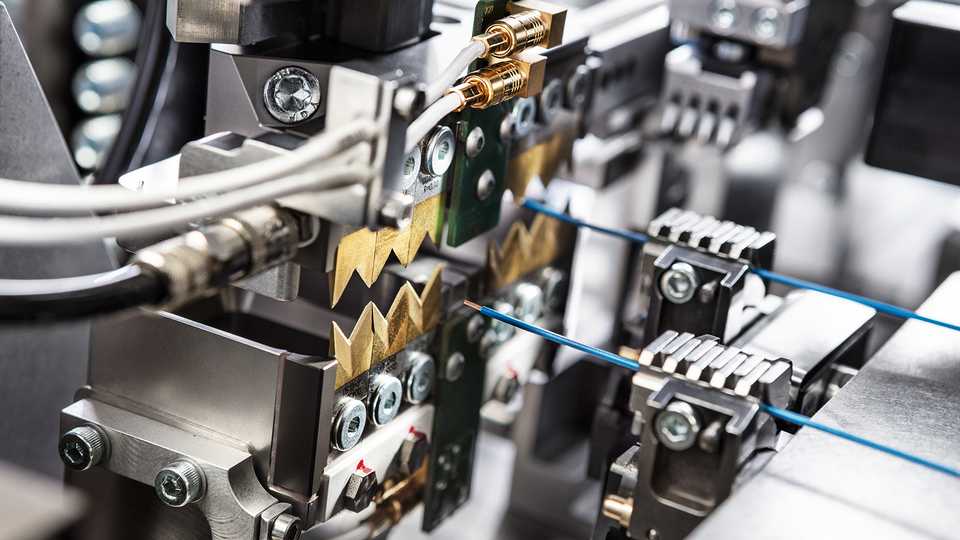

What Is the Komax Zeta Machine?

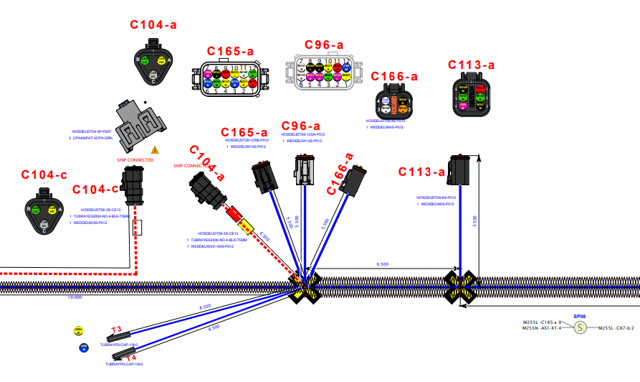

The Komax Zeta is an automated

wire processing system that handles multiple wire types, sizes, and configurations without tooling changeover. It performs cutting, stripping, crimping, labeling, and routing in one continuous workflow. Operators feed production data and wire lists into the machine, eliminating much of the manual setup. The modular design allows configuration of terminal modules, marking stations, or bundling functions to match a manufacturer’s requirements.

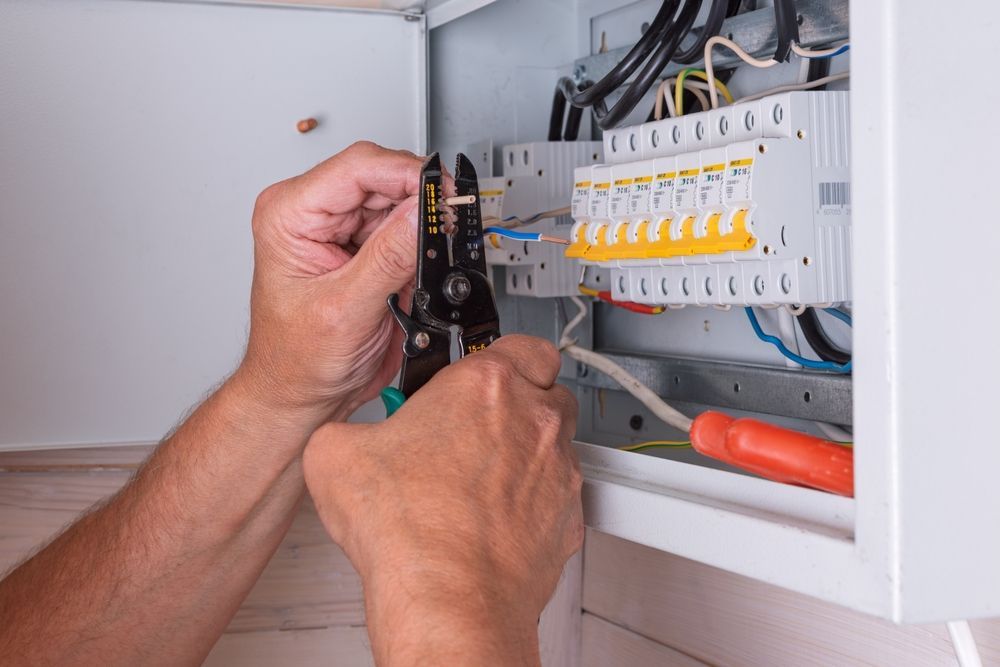

Manual Wire Processing Challenges

Traditional wire harness assembly often involves multiple steps done by hand. Each wire must be cut, stripped, crimped, labeled, and organized individually. The process takes time and depends on operator skill and consistency. Fatigue, technique variation, and human error can lead to defects or rework.

As harness designs become more complex and production volumes increase, manual methods create delays. Switching between wire types, adjusting tooling, and repeating the same tasks adds downtime and increases labor costs. These limitations make it difficult to scale efficiently or meet tight production schedules.

How Komax Zeta Improves Wire Processing

The Komax Zeta simplifies production by combining multiple wire handling steps into one

controlled process. It reduces setup between jobs, limits handling errors, and keeps production moving without interruptions. Operators spend less time staging materials or adjusting equipment, which frees up resources and shortens lead times.

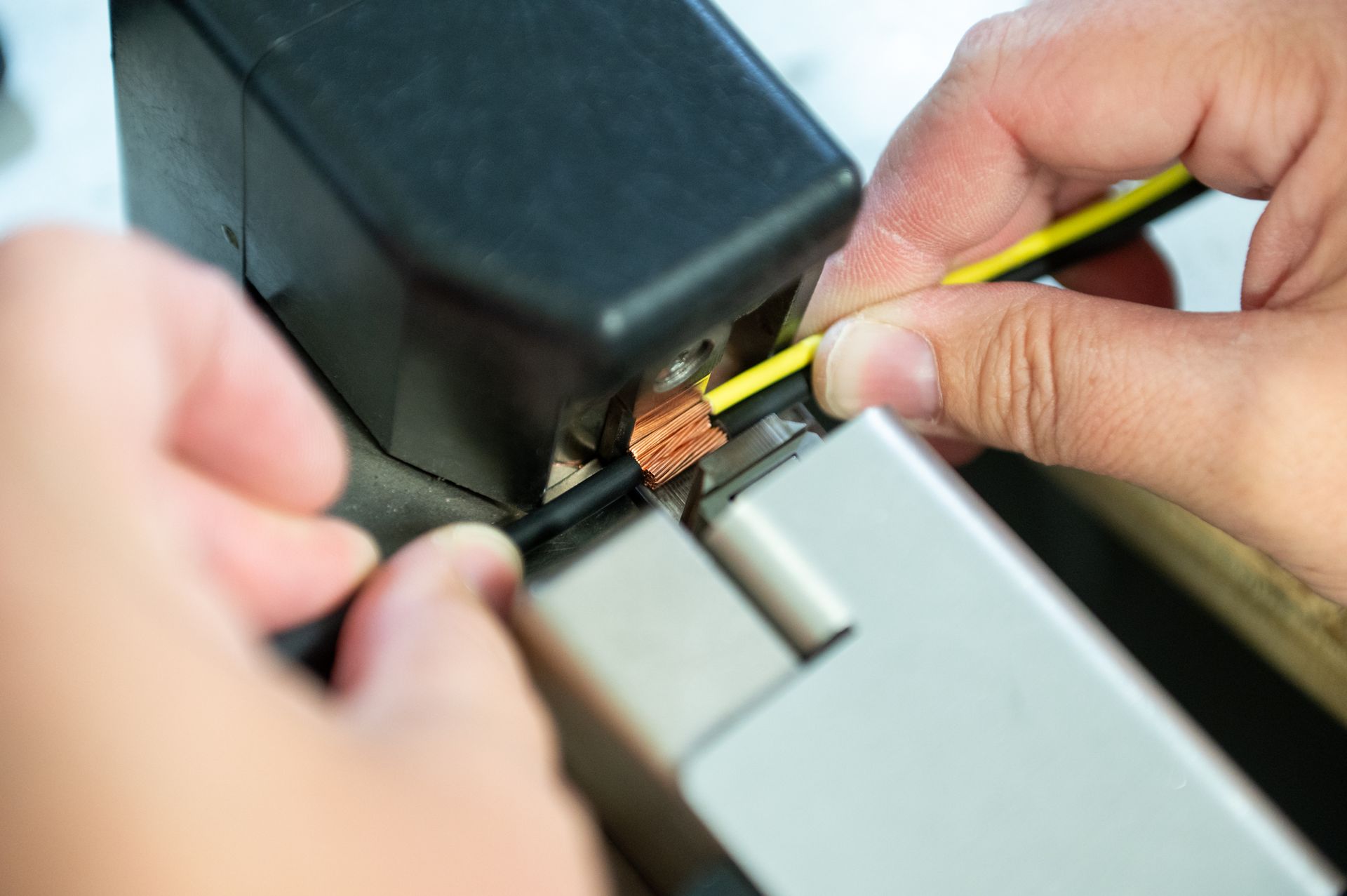

Automated Cutting and Crimping

The Komax Zeta handles cutting and crimping in a unified workflow, using precision tools programmed with job parameters. The machine processes a wide range of wire sizes and terminals, applying consistent settings for each job. It reduces variation and lowers the risk of manual errors in cut length or crimp height.

Automation also cuts down on manual setup tasks, such as measuring, tool changes, or recalibrating crimp settings between runs.

Smart Programming and Wire Libraries

High-mix production often requires fast changeovers and precise job setup. Built-in software makes that possible by storing wire data, terminal specifications, strip lengths, and crimp settings in organized libraries. Operators can load wire lists directly from job files or manufacturing systems, reducing the risk of entry mistakes.

Once a job is saved, the Komax Zeta retrieves the settings automatically, making it easier to switch between projects without stopping production.

Batch Production for Lean Workflows

Producing harnesses in batches can reduce waste, improve traceability, and shorten lead times. The Komax Zeta is designed to support this approach through automated sequencing and job queuing. Multiple wire types, lengths, and terminations can be processed in a single run without stopping to reconfigure the machine.

This capability aligns well with lean manufacturing goals, where efficiency and consistency are key to meeting delivery schedules and controlling costs.

Benefits of Komax Zeta for OEM Manufacturers

Automating wire processing brings measurable gains to OEM operations. The Komax Zeta reduces manual labor, cuts down on errors, and accelerates production timelines. Consistent output and faster changeovers make it easier to meet tight deadlines while maintaining quality across every harness configuration.

Faster Turnaround and Higher Throughput

The Komax Zeta completes multiple wire processing steps in one uninterrupted sequence. This reduces idle time between operations and eliminates the need for manual transitions from one task to the next. With programmable wire lists and automatic job setup, the system moves quickly from batch to batch without delays.

Higher throughput allows OEMs to meet production targets without increasing headcount or extending shifts.

Improved Quality and Consistency

Manual wire processing can lead to variation in cut lengths, strip depth, or crimp quality. The Komax Zeta reduces this variability by using programmable settings that apply consistent parameters across each wire. When paired with quality monitoring modules, the system can detect deviations in crimp force and other key metrics during production.

Fewer handling steps and controlled automation contribute to more repeatable results across batches.

How Kato Cable Delivers Precision with Komax Zeta

At Kato Cable, we use the Komax Zeta to meet tight production timelines without sacrificing consistency. Our team programs each job based on the exact wire specifications required, including cut length, strip dimensions, and terminal configurations. The machine’s automation allows us to reduce handling, speed up production, and maintain accuracy across every harness.

We configure the system with monitoring tools that help us catch irregularities early, so each assembly meets the quality standards our OEM partners expect.