Defense Wire Harnesses and Cable Assemblies

The Challenge of Defense Electrical Integration

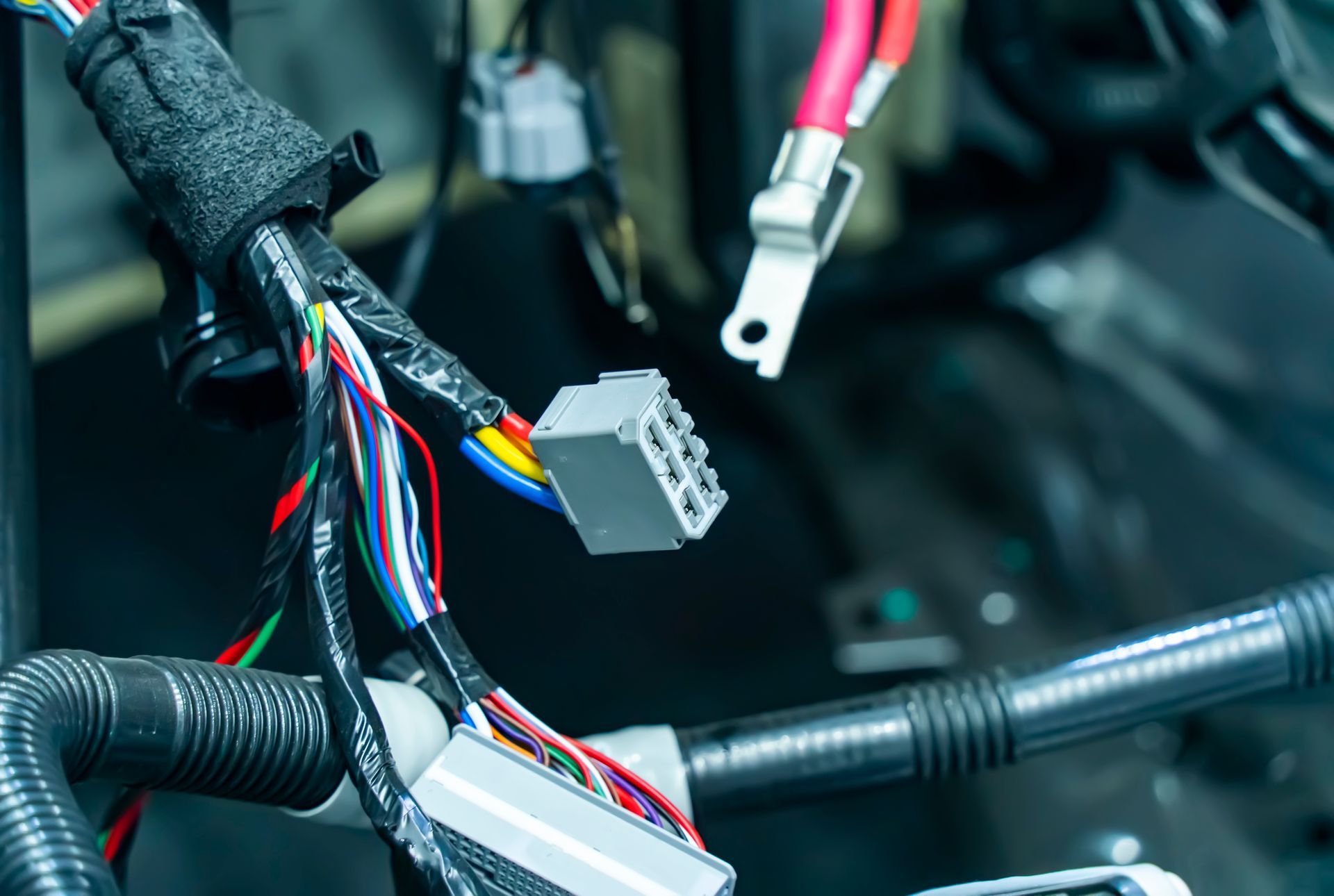

Defense systems demand rugged, mission-ready electrical infrastructure capable of withstanding the harshest environments. Equipment used in land, air, and sea operations must maintain uninterrupted connectivity despite exposure to vibration, moisture, temperature extremes, and electromagnetic interference.

OEMs in the defense sector face unique challenges when integrating electrical systems into tactical vehicles, communication platforms, radar systems, and weapons technology. Each defense wire harness must be engineered for durability, accuracy, and performance under pressure. There's no margin for error in critical missions, which makes reliability, consistency, and quality non-negotiable in every cable assembly design.

Defense Wire Harness and Cable Assembly Solutions

Kato Cable delivers defense wire harness and cable assembly solutions designed to perform in extreme and unpredictable environments. We partner with OEMs to develop custom interconnect systems that meet strict military specifications and application-specific requirements.

Each build is engineered for ruggedness, with materials and configurations selected to handle shock, vibration, moisture ingress, and long-term field use. Our team supports a range of defense applications, including ground vehicles, surveillance systems, electronic warfare equipment, and mobile command infrastructure. As a trusted defense wire harness manufacturer, we bring the technical expertise and production flexibility needed to keep programs moving without compromise.

Defense Manufacturing Standards and Quality Systems

Kato Cable operates with a quality system built to meet the rigorous demands of defense manufacturing. Our processes are aligned with military standards and best practices to ensure each assembly meets the highest levels of performance, reliability, and compliance.

Every defense cable assembly goes through controlled production workflows, detailed inspections, and full traceability. We utilize precision documentation, testing protocols, and configuration management to maintain consistency from prototype through full production. This commitment to quality helps our defense partners meet contract requirements and maintain operational readiness in the field.

Our Products are Proudly Made in the USA

Process Control & Engineering Control Services

Process Control

Precision and consistency are at the heart of every custom cable solution. Our Process Control strategies ensure each assembly meets exact specifications, from initial concept to final production. Through rigorous quality checks, standardized procedures, and real-time monitoring, we optimize efficiency while maintaining the highest level of reliability.

Engineering Control

From concept to completion, Engineering Control ensures every design is optimized for functionality, manufacturability, and long-term performance. Our expert team evaluates form, fit, and function, applies industry best practices and testing protocols, and leverages innovative solutions to deliver high-quality and cost-effective cable and harness assemblies.

Your Industry, Our Vision

The Kato Cable Advantage

The Kato Cable Advantage is a holistic approach to looking at the value that you bring to your customers, employees and community. Our customers relate directly to our responsiveness and engineering value, to the investments that we have made into efficiencies and automation, and to the key metrics of industry leading Quality and On Time Delivery. Our employees relate to a sense of inclusion, an appreciation and value to feedback, and the philosophy of making improvements every day. Our community relates to our growth and volunteerism and leadership that we strive for in our region. Together these attributes and values truly deliver the Kato Cable Advantage!

Quality & Reliability

Delivering precision-engineered wire harnesses, cable assemblies, and electro-mechanical assemblies that meet the highest industry standards.

Innovation

Continuously improving processes and technologies to provide cutting-edge solutions for diverse industries.

Customer Commitment

Building strong partnerships through collaboration, responsiveness, and tailored solutions.

Why OEMs Partner With Kato Cable for Defense

OEMs in the defense sector choose Kato Cable for our ability to deliver dependable results in high-stakes environments. We bring together technical knowledge, hands-on collaboration, and a deep understanding of military program demands.

Our team helps customers address complex design requirements, navigate compliance needs, and stay aligned with production schedules. As a defense wire harness manufacturer, we focus on long-term performance and consistent quality. Customers value our commitment to detail, accountability, and the ability to deliver on critical objectives without compromise.

Our Certifications

Stay Connected with our Blog

Industry Template Contact Us

We will get back to you as soon as possible.

Oops, there was an error sending your message. Please try again later.

Request a Quote for Defense Cable Assemblies

Mission success starts with dependable interconnect solutions. Kato Cable provides custom-engineered defense cable assemblies and wire harnesses built to meet the highest standards of durability and performance.

If you're looking for a defense

wire harness manufacturer that understands your technical challenges and delivers with precision, we’re ready to help. Request a quote today to begin a conversation with a team committed to supporting your goals from design through production.