Power Generation Wiring Harnesses and Cable Assemblies

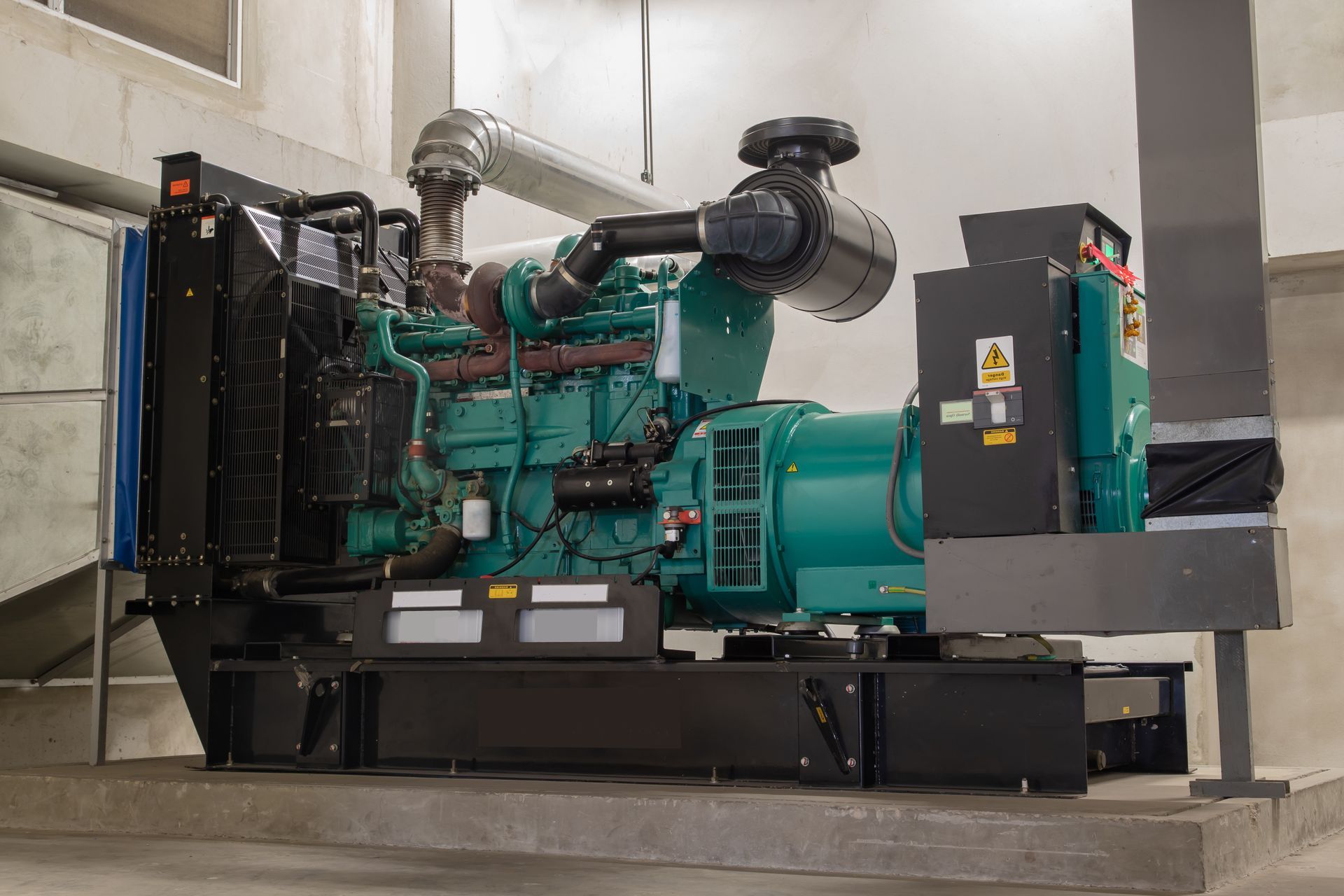

Empowering Power Generation — Big and Small

Our products range from battery cables to control panels and can be found in small to large engines — from lawnmowers to large industrial power generators that power vital data centers.

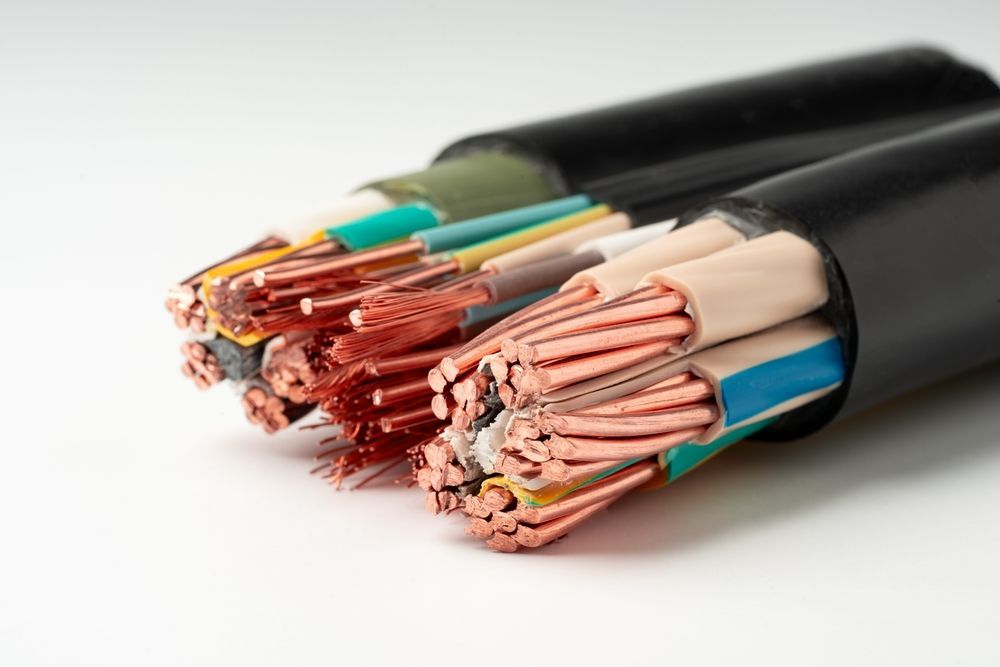

What is a Power Generation Cable Assembly?

A power generation cable assembly is a bundled group of electrical cables enclosed in a protective jacket, designed to carry power, control signals, or data within generator systems. These assemblies connect key components and support the safe and efficient operation of both standby and continuous-use equipment.

Built to perform in challenging environments, power generation cable assemblies are engineered to resist heat, vibration, and abrasion. They provide consistent power delivery in demanding conditions.

Power Generation Assemblies - How it Works

What it is:

A power generation wire harness is a bundled collection of wires, cables, and connectors designed to safely and efficiently transmit electrical power within standby power generation equipment.

Function:

These harnesses connect various components, such as generators and batteries, ensuring reliable power distribution. Built to withstand harsh conditions like heat and moisture, the wire harness improves safety, reduces the risk of electrical failures, and simplifies installation and maintenance in backup power systems.

Benefits

Enhanced Safety

• Reduced Risk of Electrical Failures: Wire harnesses bundle wires together, reducing the chances of accidental contact between wires, which can lead to short circuits or electrical fires.

• Simplified Troubleshooting: A wire harness is organized, making it easier to locate and address potential electrical faults, which increases safety for operators and maintenance staff.

Efficiency and Organization

• Reduced Clutter: Bundling wires into a harness reduces clutter and makes installation simpler and faster, improving overall efficiency.

• Simplified Installation: The pre-assembled wire harness allows for quick and accurate installation without the need to manually route each wire, reducing labor costs and installation time.

Cost-Effective

• Reduced Manufacturing Time: Since wire harnesses are pre-assembled, manufacturers save time on wiring assembly, leading to cost reductions.

• Minimized Maintenance Costs: A well-constructed wire harness reduces wear and tear on individual wires, leading to fewer repairs or replacements, which can lower maintenance costs.

Space Optimization

• Compact Design: By organizing multiple wires into a single bundle, wire harnesses help reduce the amount of space required for electrical systems, making it easier to fit the harness into tight spaces within the power generation system.

Improved Aesthetics

• Clean and Organized Appearance: Power generation wire harnesses offer a cleaner, more organized look, especially in systems with a large number of wires, which is important for both functionality and visual inspection.

Examples of Applications

Marine Power Generation

• Application: Marine power generation systems, such as those found on ships or offshore platforms, use wire harnesses to connect generators, motors, control panels, and safety systems.

• Why: Marine environments are challenging, with exposure to saltwater, humidity, and rough conditions. Wire harnesses help keep electrical systems safe, organized, and functioning under these demanding circumstances.

Industrial Machinery

• Application: Wire harnesses are commonly used in industrial power generation machinery like gas and steam turbines, compressors, and heavy-duty motors.

• Why: Industrial machines operate in environments that require high performance and resistance to mechanical stress, heat, and vibration. Wire harnesses help protect the electrical connections, making the machinery more efficient and reducing the risk of electrical malfunctions.

Battery Storage Systems

• Application: In large-scale battery storage systems (such as those used for grid stabilization or backup power), wire harnesses are used to interconnect batteries, inverters, and controllers.

• Why: These systems require high current-carrying capabilities and tight organization to prevent overheating and ensure the efficient and safe flow of electricity. Wire harnesses also simplify installation and maintenance in such large-scale setups.

Uninterruptible Power Supplies (UPS)

• Application: UPS systems, which provide backup power to critical equipment like data centers, hospitals, and manufacturing plants, use wire harnesses to connect batteries, inverters, and control circuits.

• Why: UPS systems require reliability and fast response times. Wire harnesses help ensure the system operates smoothly and is capable of quickly switching between grid power and backup power when needed.

Data Centers

• Application: Wire harnesses are used in data centers to manage power distribution to servers, cooling systems, and backup generators.

• Why: Data centers rely on constant power available.

OEM Support for Power Generation Cable Design

Power generation systems demand accurate, dependable connections tailored to specific performance requirements. Kato Cable partners with OEMs to develop wire harnesses and cable assemblies that match electrical loads, environmental conditions, and spatial constraints within the equipment.

Our team provides material and component selection guidance, routing strategies, and manufacturability insight early in the design process. This support helps reduce rework, improve consistency, and maintain production schedules.

Process Control & Engineering Control Services

Process Control

Precision and consistency are at the heart of every custom cable solution. Our Process Control strategies ensure each assembly meets exact specifications, from initial concept to final production. Through rigorous quality checks, standardized procedures, and real-time monitoring, we optimize efficiency while maintaining the highest level of reliability.

Engineering Control

From concept to completion, Engineering Control ensures every design is optimized for functionality, manufacturability, and long-term performance. Our expert team evaluates form, fit, and function, applies industry best practices and testing protocols, and leverages innovative solutions to deliver high-quality and cost-effective cable and harness assemblies.

Why OEMs Trust Kato Cable for Interconnect Solutions

In power generation, every component must perform without fail. Kato Cable delivers wire harnesses and cable assemblies designed for the demands of high-load, high-vibration environments. Our solutions are built to handle the electrical and mechanical stress found in generator sets, control panels, and switchgear.

OEMs in this space choose Kato for our technical support, product consistency, and ability to meet exacting specifications. Our attention to design detail and build quality helps customers avoid costly delays and meet tight delivery timelines with confidence.

Our Products are Proudly Made in the USA

The Kato Cable Advantage

The Kato Cable Advantage is a holistic approach to looking at the value that you bring to your customers, employees and community. Our customers relate directly to our responsiveness and engineering value, to the investments that we have made into efficiencies and automation, and to the key metrics of industry leading Quality and On Time Delivery. Our employees relate to a sense of inclusion, an appreciation and value to feedback, and the philosophy of making improvements every day. Our community relates to our growth and volunteerism and leadership that we strive for in our region. Together these attributes and values truly deliver the Kato Cable Advantage!

Quality & Reliability

Delivering precision-engineered wire harnesses, cable assemblies, and electro-mechanical assemblies that meet the highest industry standards.

Innovation

Continuously improving processes and technologies to provide cutting-edge solutions for diverse industries.

Customer Commitment

Building strong partnerships through collaboration, responsiveness, and tailored solutions.

Your Industry, Our Vision

Our Certifications

Stay Connected with our Blog

Power Generation Contact Us

We will get back to you as soon as possible.

Oops, there was an error sending your message. Please try again later.

Looking for Support?

Our team is here to help. Whether you’re looking for a custom solution or need support with an existing project, we’re just a message away. Reach out today, and let’s find the right solution for you.