Improving Wire Harness Outcomes Through Supplier Partnership

Share Article:

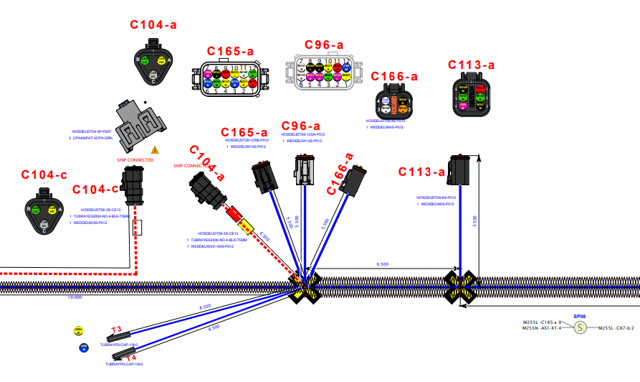

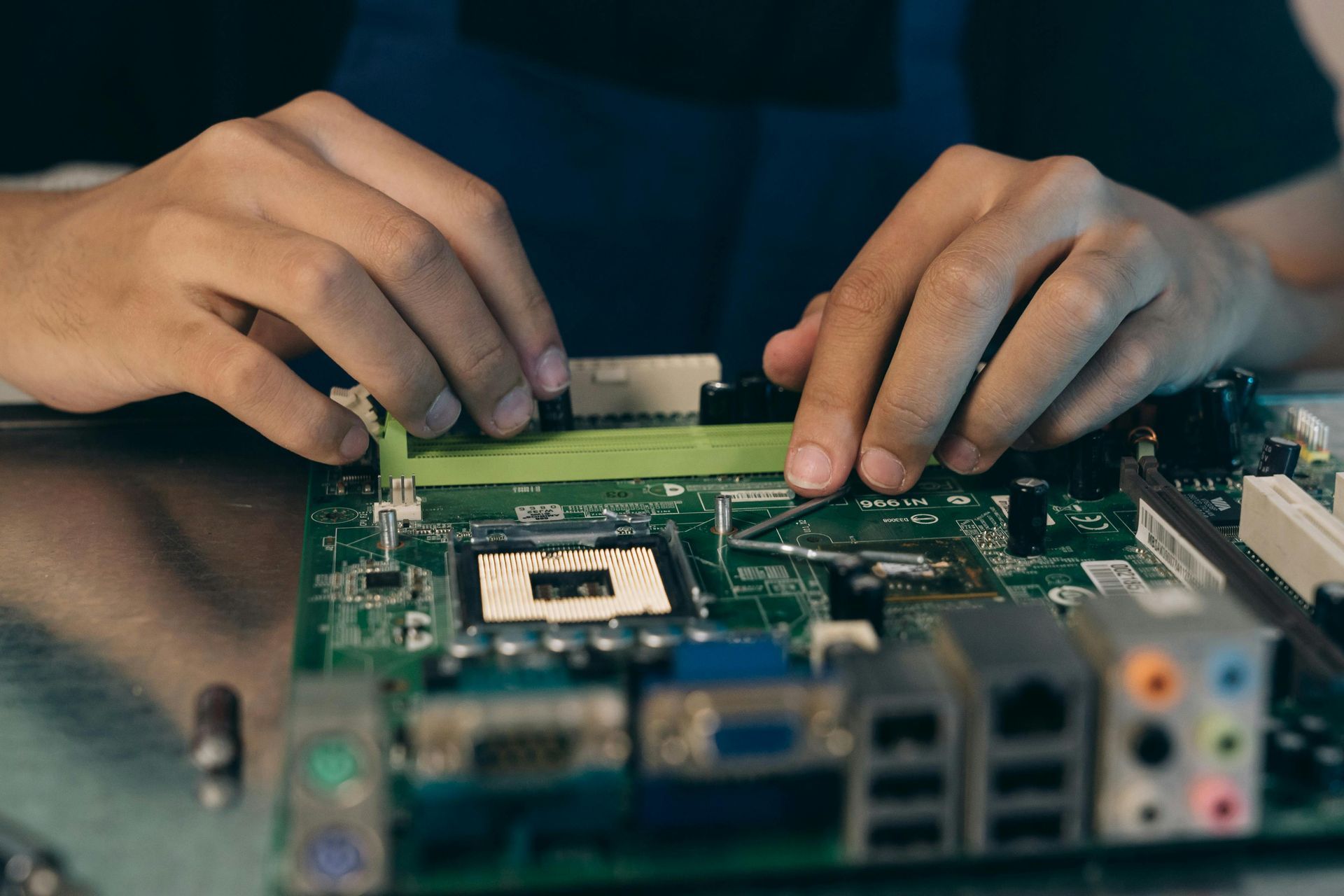

More OEMs are looking for ways to improve product performance while managing cost, reliability, and production timelines. Wire harnesses and control panels are central to these goals, but they’re often treated as fixed components once designs are set. Without supplier input, small issues in routing, layout, or part selection can lead to longer builds, higher labor costs, and quality problems down the line. Bringing a manufacturing partner in early helps simplify production, reduce errors, and create better long-term outcomes.

Why Supplier Partnerships Matter in Wire Harness Production

A complete wire harness or control panel design doesn’t always translate into efficient production. Without considering how components will be sourced, routed, and assembled, designs can create bottlenecks that slow production or introduce preventable quality issues.

Supplier partnerships give OEMs access to hands-on expertise during the early stages of development. This collaboration helps align design choices with automated processes, standardized parts, and efficient layouts, leading to fewer delays, lower costs, and more reliable outcomes.

Challenges OEMs Face in Wire Harness Production

Even well-developed wire harness or control panel designs can create challenges once they reach production. Complex routing, non-standard parts, and limited documentation can increase assembly time and raise the chance of error. When designs aren't reviewed for manufacturability, teams spend more time adjusting builds than completing them.

Sourcing can add another layer of difficulty. Long lead times, part shortages, and a high number of unique components make it harder to maintain consistent output. These issues can slow delivery schedules, drive up costs, and strain internal resources. Without a manufacturing partner to help address these obstacles early, small design choices can turn into larger production problems.

The Cost of Over-Engineered or Poorly Designed Assemblies

Wire harnesses that are difficult to build often lead to avoidable rework, longer cycle times, and higher labor costs. Assemblies with unnecessary complexity, such as excess wire length, tight bends, or hard-to-reach connectors, can slow down production and increase the chance of mistakes on the line.

Poorly optimized designs also affect testing, troubleshooting, and long-term serviceability. When harnesses aren't laid out for efficient assembly and inspection, quality issues become harder to catch before shipment. These gaps can result in warranty claims, equipment downtime, and added service costs in the field.

Key Elements of Manufacturable Wire Harness Design

Building for manufacturability starts with clear, consistent design choices that align with production capabilities.

Standardized Components and Materials

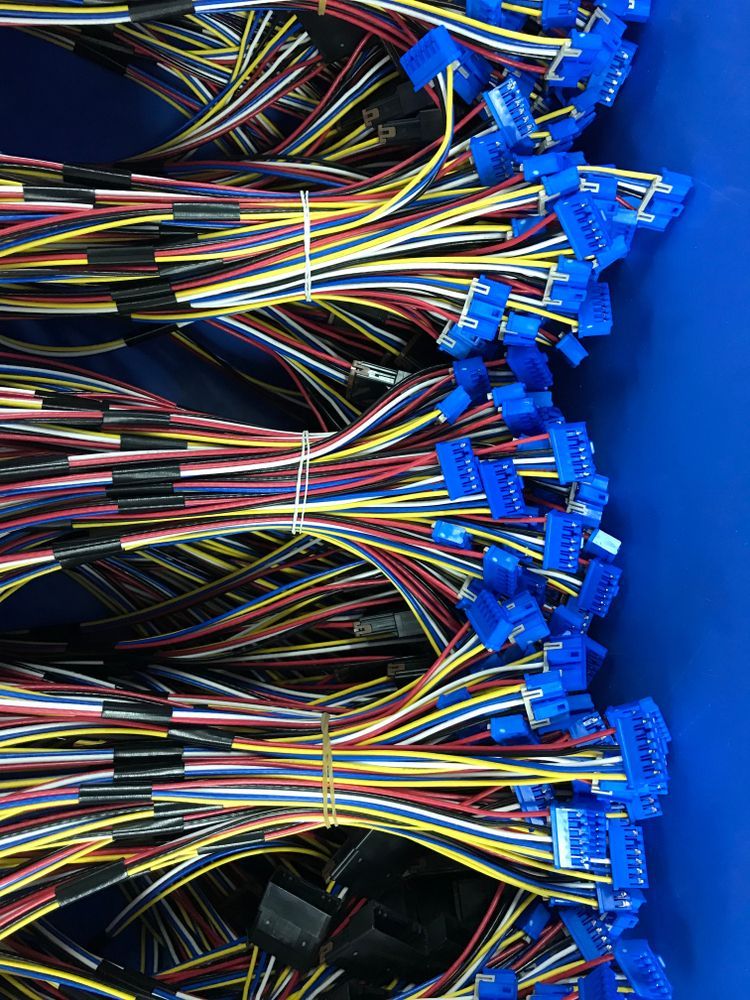

Using a wide range of unique parts may meet technical requirements, but it often adds unnecessary cost and complexity. Non-standard connectors, terminals, or wire gauges can slow procurement, increase setup time, and complicate inventory management.

Standardizing components across assemblies makes sourcing more predictable and allows for faster processing during production. It also supports automation, reduces the chance of handling errors, and simplifies documentation and testing procedures.

Efficient Routing and Layout

Routing and layout choices influence how quickly and accurately a wire harness can be assembled. Designs that include sharp angles, congested paths, or overlapping circuits can create stress points and make handling more difficult on the production floor.

A clean layout reduces wire length, avoids pinch points, and allows enough space for secure fastening and airflow. Clear routing improves visibility during inspection and helps teams identify connection points without delays or confusion.

Labeling, Identification, and Access

Clear labeling and identification reduce mistakes during assembly, testing, and service. When wires, connectors, and terminals in both harnesses and control panels are easy to read and trace, technicians spend less time verifying connections or referencing documentation.

Good visibility also improves accuracy during inspections and future maintenance. Accessible designs that allow tools and hands to reach connection points make production faster and field repairs more efficient, lowering both labor time and the chance of damage during handling.

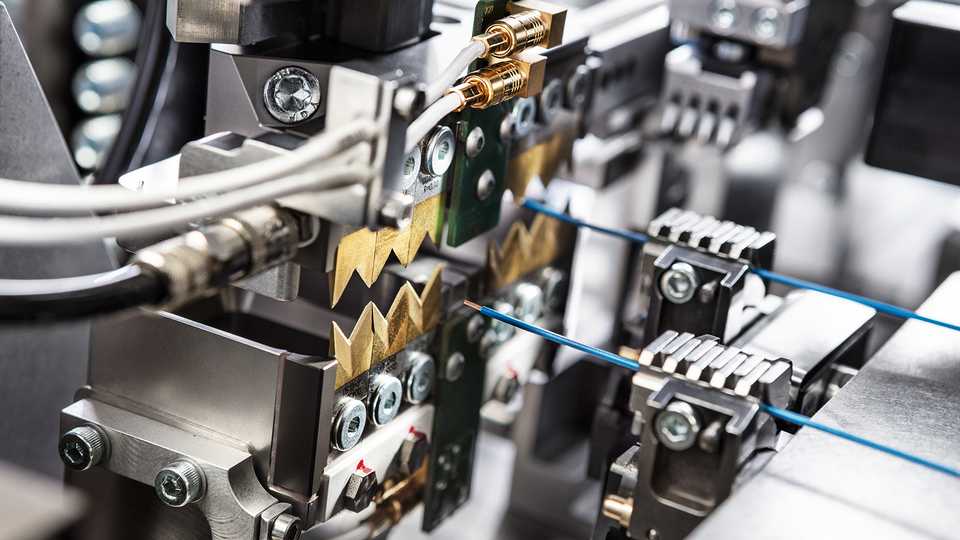

Compatibility with Automated Assembly

Designs that align with automated processes help reduce manual labor, speed up production, and improve consistency across units. Wire harnesses that use consistent lengths, pre-terminated connectors, and repeatable layouts are easier to cut, strip, crimp, and test using automated equipment.

When components are selected and positioned for machine compatibility, production lines can run more efficiently and with fewer interruptions. This approach also lowers the risk of human error and helps maintain quality across higher volumes.

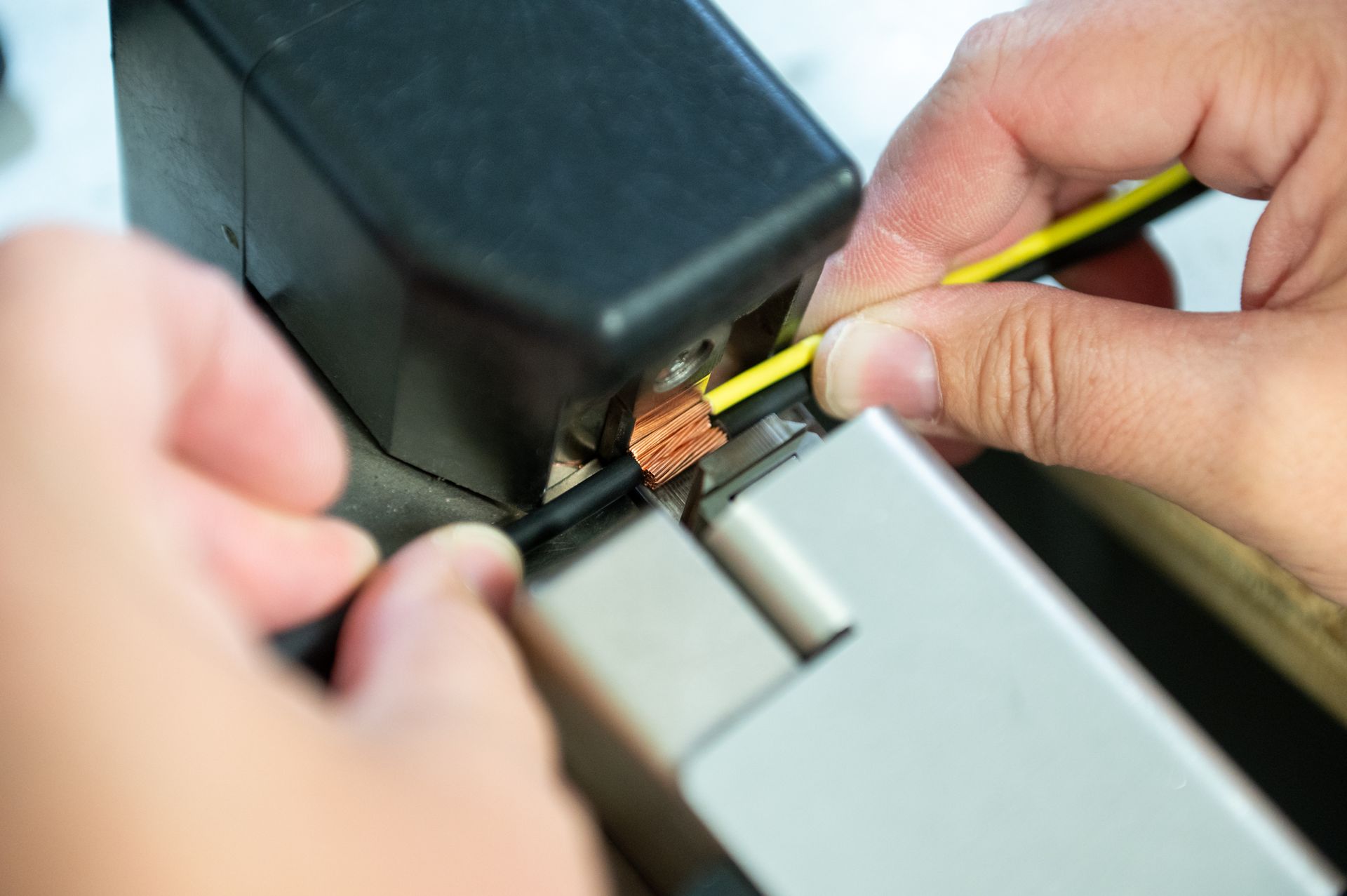

How DFM Drives Long-Term Performance and Reliability

Designing for manufacturability (DFM) does more than streamline production. It helps reduce wear on components, improve consistency across builds, and lower the risk of electrical faults in the field. When harnesses are built from tested processes using repeatable methods, long-term reliability improves without adding unnecessary cost.

DFM principles also make it easier to scale production without sacrificing quality. Consistent designs are easier to document, replicate, and test, which leads to stronger results throughout the product’s lifecycle.

What OEMs Gain from Partnering with an Experienced Manufacturing Supplier

An experienced supplier helps bridge the gap between design intent and production reality. Early input on harness or panel layouts can eliminate unnecessary complexity, reduce part counts, and improve flow on the assembly line. These adjustments lead to faster builds, lower costs, and fewer production issues.

Beyond production, a knowledgeable partner understands testing requirements, documentation standards, and

industry compliance. That level of support helps OEMs launch more reliable

products while staying on schedule and within budget.

Build Smarter with Kato Cable

Partnering with Kato Cable helps OEMs create wire harnesses and control panels that are ready for efficient, high-quality production. Our team works alongside customers to adjust designs for automation, reduce complexity, and meet performance requirements without adding unnecessary cost.

If you’re looking to improve performance and simplify production, we’re ready to help.

Request a quote to start your next project.