Wire Twisting: Purpose, Benefits, and Applications

Share Article:

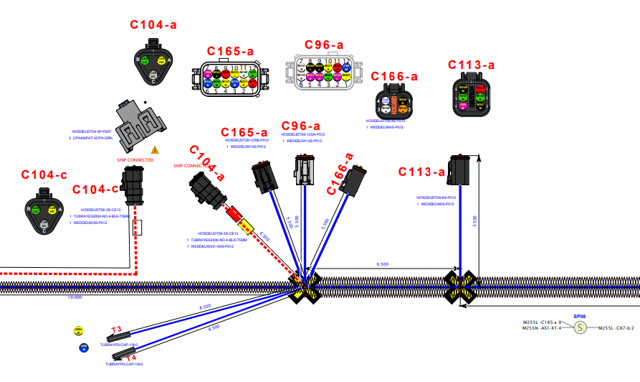

Electrical systems in OEM equipment are becoming more complex. As wiring density increases, so do the challenges around signal performance, noise reduction, and long-term reliability. Wire twisting plays a direct role in solving these problems. It’s a standard technique in custom cable assemblies that helps reduce interference, improve consistency, and protect performance in demanding environments.

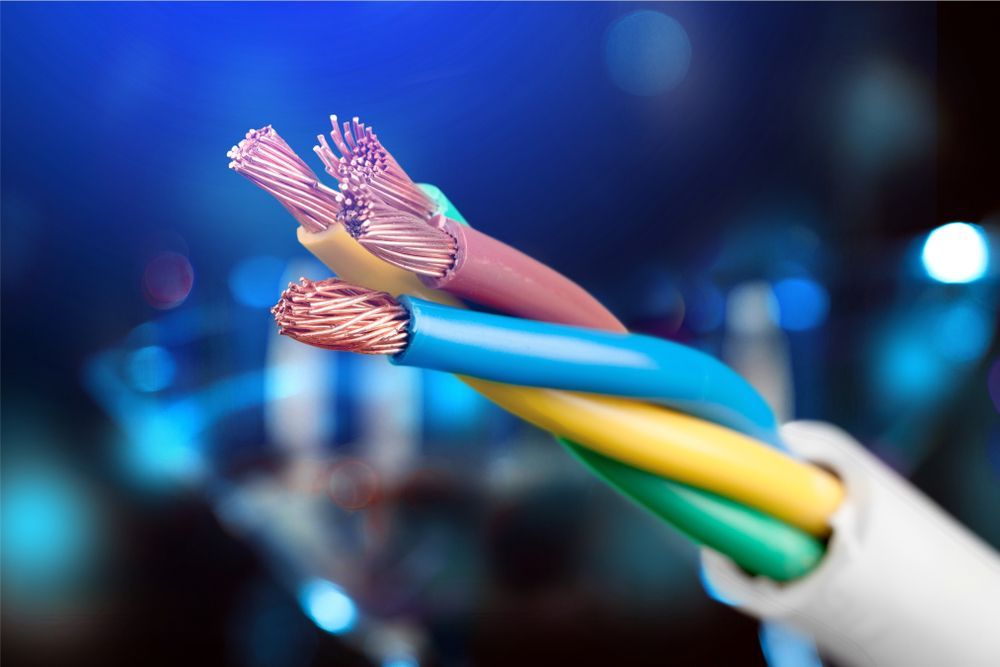

What Is Wire Twisting?

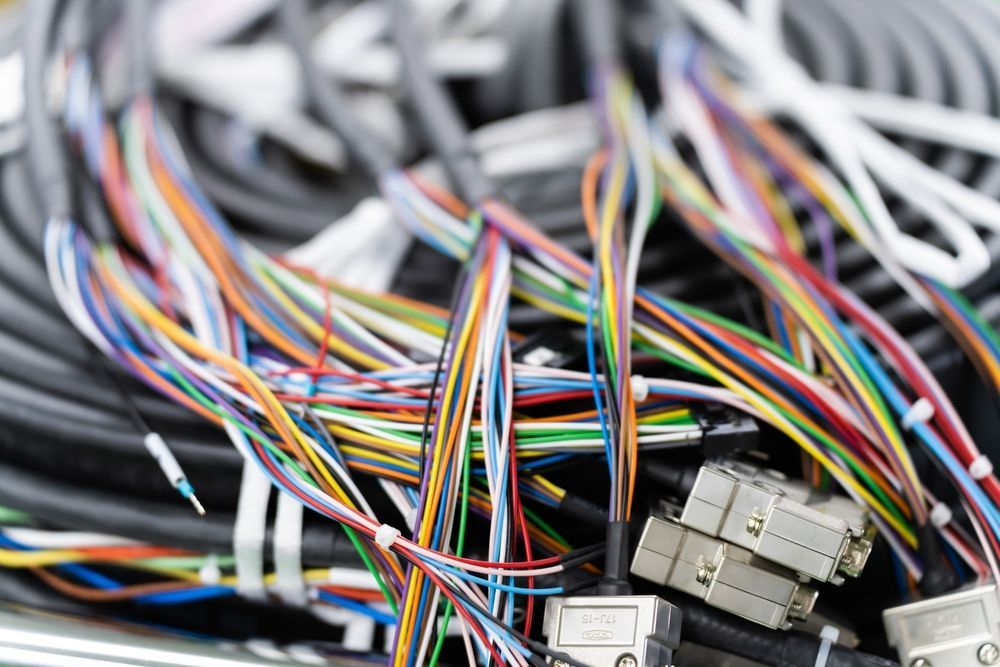

Wire twisting involves winding two or more conductors together in a uniform spiral. Originally developed to reduce interference in early telegraph and telephone systems, the method has become standard in modern cable assembly. It helps meet strict performance requirements for power, data, and signal transmission.

Twisting conductors creates consistent spacing and balanced geometry, which improves electromagnetic performance. This is especially valuable in multi-conductor cables where exposure to noise, vibration, or electromagnetic interference (EMI) could disrupt function.

Why Wire Twisting Matters for OEM Performance

OEMs in transportation, industrial automation, and heavy equipment expect consistent performance across every electrical connection. Twisted wire configurations help meet that expectation. They contribute to signal integrity, reduce the risk of failure, and help assemblies perform under mechanical and electrical stress.

In complex equipment, a poorly routed or unstable wire can lead to downtime, inaccurate data, or degraded performance. Twisting adds structure and repeatability to the cable, making it easier to install and more reliable in operation. For high-density assemblies or systems exposed to movement and vibration, this added stability plays a key role in long-term performance.

How Twisted Wires Improve Electrical Reliability

Twisted wires help maintain consistent electrical characteristics across a harness. Equal spacing and mirrored geometry reduce impedance fluctuations and signal distortion, supporting reliable power and data transmission, even in tightly packed or noise-sensitive assemblies.

Reducing Interference and Crosstalk

Electromagnetic interference and crosstalk can disrupt signal clarity in compact or high-speed systems. Twisting conductors balances the electromagnetic fields, which reduces noise pickup and prevents signals from bleeding between wires. This improves communication accuracy and system stability in sensitive applications.

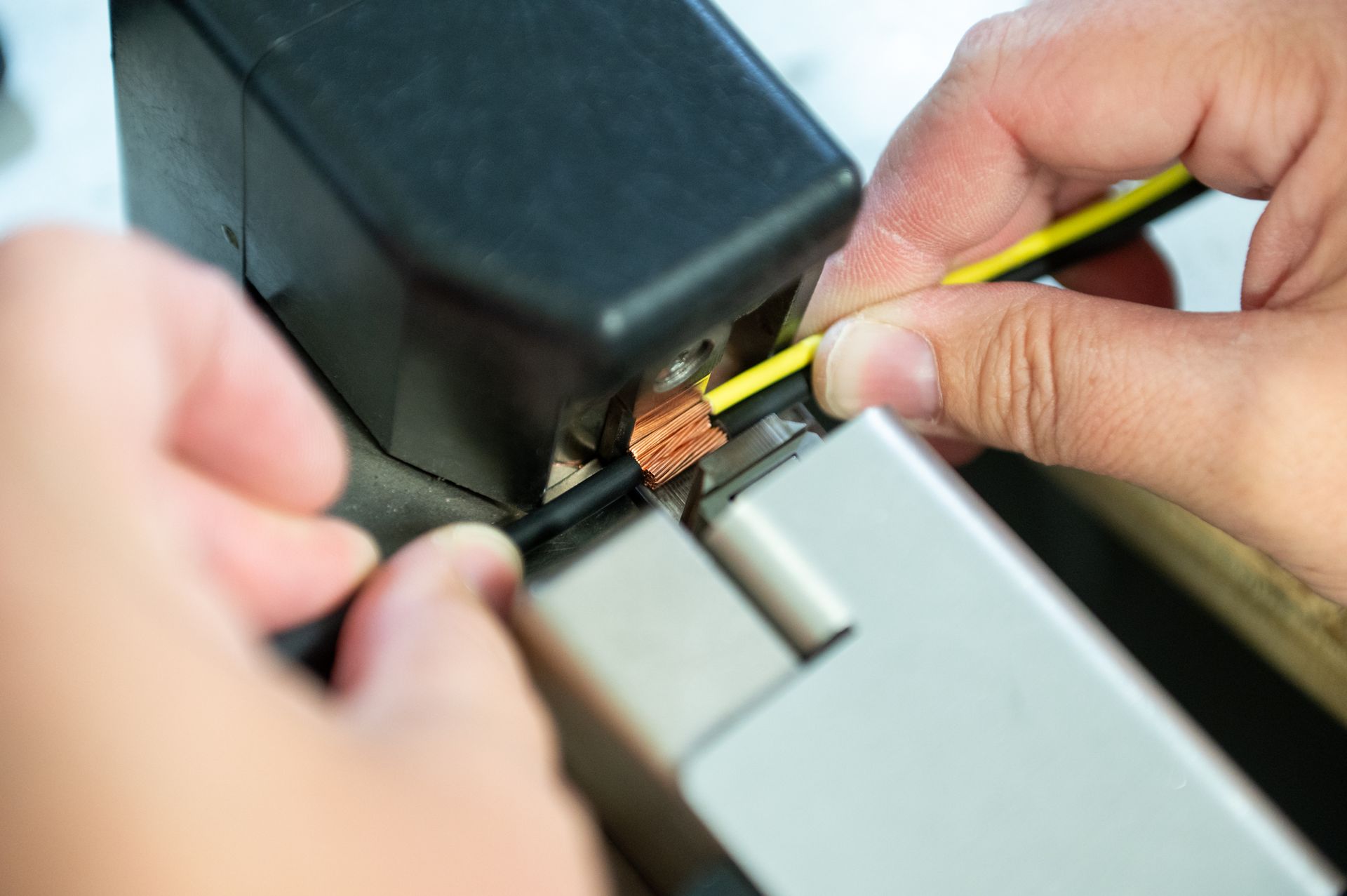

Enhancing Durability and Flexibility

Twisting adds structure to the cable, which helps prevent kinks, snags, and uneven stress during installation or movement. The uniform pattern distributes mechanical load more evenly across the conductors, reducing wear over time.

In harnesses exposed to vibration, motion, or repeated handling, this added flexibility extends the usable life of the assembly while helping it maintain consistent performance.

Common Wire Twisting Applications in Modern Equipment

Wire twisting is used across a

range of OEM assemblies where electrical stability and physical resilience matter. It supports both signal and power transmission in systems that face vibration, EMI, or space constraints. Applications span vehicles, generators, industrial controls, and specialized machinery.

Automotive and Heavy Equipment

Wire twisting is used in harnesses for powertrains, sensors, lighting, and control systems. In heavy-duty environments, it helps cables resist vibration, heat, and movement without signal disruption. Structured wire layouts also make routing more predictable, which improves reliability in systems that operate under continuous mechanical and thermal stress.

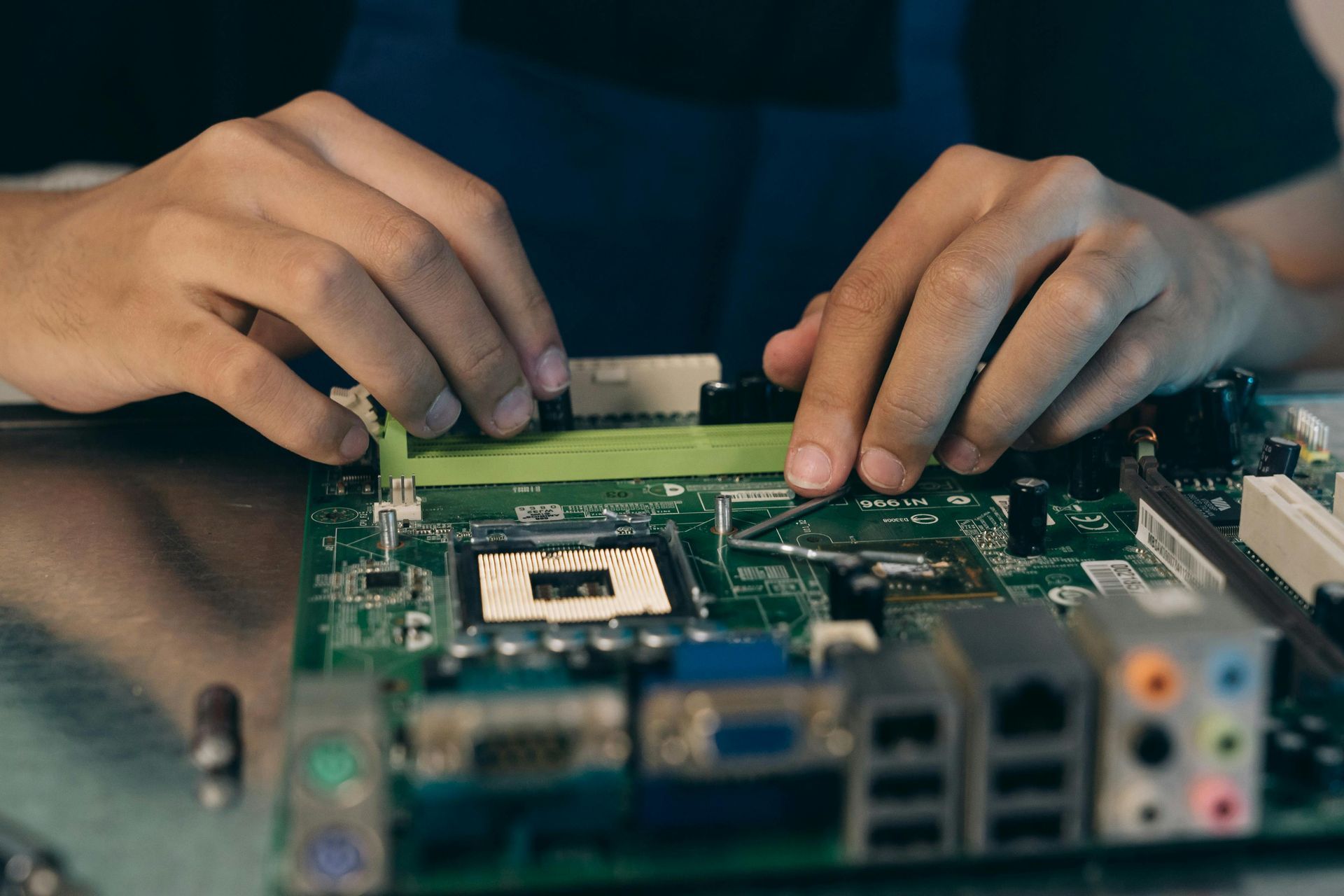

Industrial and Electronics Manufacturing

Twisted wire assemblies are common in control panels, robotic systems, and

industrial machinery. These environments often involve dense wiring, moving parts, and electrical noise. Consistent twisting helps preserve signal clarity and keeps wiring stable during repeated motion, tight routing, and exposure to interference from nearby equipment.

Specialized Vehicles and Equipment

Twisted wire assemblies are used in fire trucks, generators, marine engines, and off-road machinery. These systems run in harsh conditions where electrical noise, vibration, and shifting components can affect performance. Twisting maintains consistent wire geometry, limits interference, and improves the long-term stability of harnesses used in control, lighting, and engine systems.

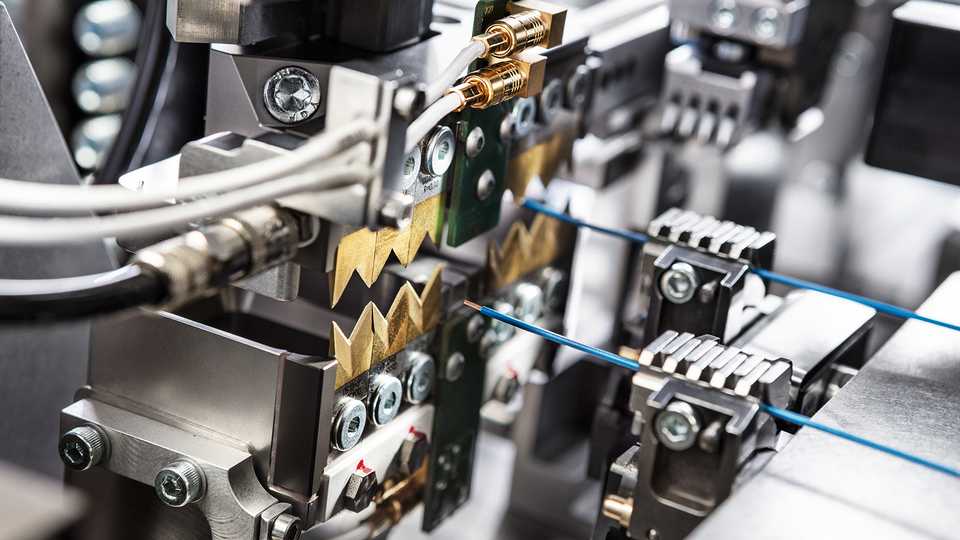

Choosing the Right Wire Twisting Method

Not all wire twisting techniques perform the same across different applications. Twist pitch, conductor type, insulation material, and layout all affect how a cable behaves in the field. Tight twists may reduce noise more effectively but can increase stiffness. Looser twists offer more flexibility but may allow more interference. The right method depends on the electrical requirements, physical routing, and mechanical stress the assembly will face.

Working with a manufacturing partner that understands these tradeoffs ensures the final product matches the application. At the engineering stage, precise decisions around twist configuration contribute directly to reliability, performance, and ease of installation.

How We Engineer Reliable Wire Twisting Solutions

At Kato Cable, wire twisting is built into the

design process, not added as a secondary step. We evaluate every harness based on how it will be used, where it will be installed, and what types of

wire processing or mechanical challenges it needs to overcome. That includes selecting the right twist pitch, conductor type, and insulation to match the application.

Our engineers work closely with customers to meet specific goals for EMI reduction, cable routing, and durability. Through a combination of design expertise, automation, and hands-on quality control, we produce twisted wire assemblies that perform reliably under real-world conditions.

Partner with Kato Cable for Custom Wire Harness Solutions

Wire twisting improves the performance, consistency, and durability of complex assemblies. At Kato Cable, it’s one part of a broader approach to building reliable interconnect solutions for OEMs. We collaborate closely with your team to align design, production, and performance goals at every stage of the project.

Looking for a partner who understands the technical demands of your equipment? Request a quote or follow us on LinkedIn and Facebook to connect.