Cable Assembly vs Wire Harness: What OEMs Need to Know

Share Article:

OEMs in the automotive, electronics, and industrial equipment industries rely on dependable electrical systems to power critical operations. Selecting the wrong interconnect solution can lead to system failures, added maintenance, or costly downtime. A key part of that reliability starts with choosing the right interconnect solution. Cable assemblies and wire harnesses are both essential components, but they serve different functions and perform best under specific conditions. Knowing the difference between the two helps engineers and procurement teams make smarter design and sourcing decisions.

What is a Cable Assembly?

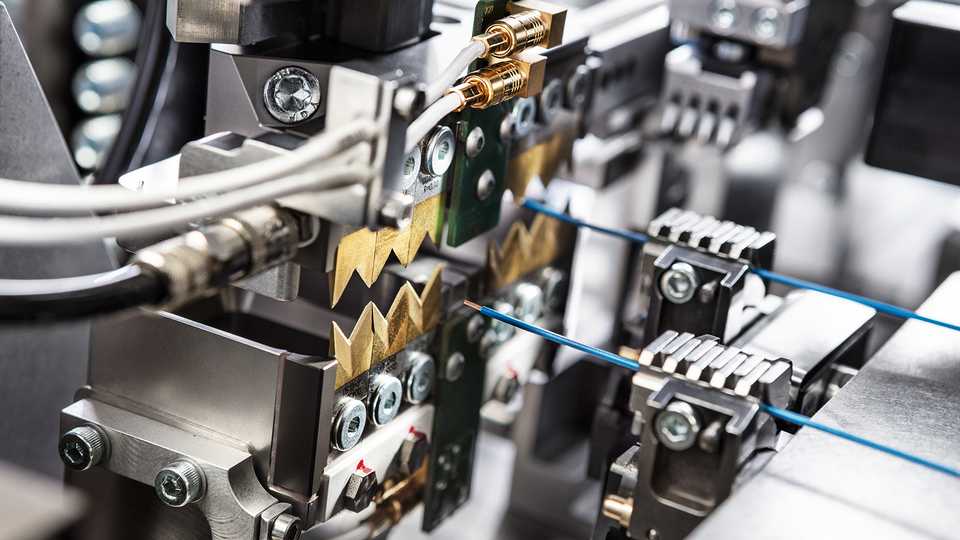

A cable assembly is a group of wires or cables bundled together within a single, unified jacket. These assemblies are designed to transmit power, data, or signals efficiently while protecting the internal conductors from environmental stressors such as moisture, heat, abrasion, or chemicals. The outer sheath is typically made of durable materials like thermoplastic, rubber, or vinyl, providing robust shielding and strain relief.

Cable assemblies are often custom-built to meet the precise specifications of a system, with terminations, connectors, and lengths tailored to fit tight spaces or complex layouts. Their design makes them ideal for high-performance applications that require durability, consistent signal transmission, and long-term reliability in demanding conditions.

What is a Wire Harness?

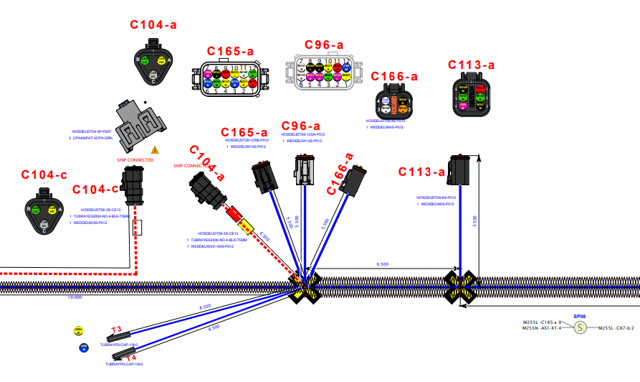

A wire harness is an organized assembly of individual wires or cables grouped together using ties, lacing, sleeves, or conduit. Unlike cable assemblies, wire harnesses typically leave the conductors exposed at various points, offering a more flexible and lightweight option for routing electrical connections through equipment or machinery.

Wire harnesses are commonly used in controlled environments where protection from harsh conditions is less critical. They simplify installation by keeping wires neatly bundled, reducing clutter, and minimizing the risk of shorts or interference. Harnesses can be customized to fit the physical layout of a system, improving assembly efficiency and overall organization.

Cable Assembly vs Wire Harness: What’s the Difference?

Cable assemblies offer enclosed protection for demanding environments. Wire harnesses organize and route wires in more controlled settings. The right choice depends on the application, conditions, and system complexity.

Application

Cable assemblies are commonly used in environments where exposure to moisture, heat, or vibration is a concern. They’re found in equipment like generators, marine systems, and industrial machinery that demand sealed, rugged connections. Their protective jacketing helps ensure stable performance under stress.

Wire harnesses are often used inside enclosures or vehicles where the environment is more controlled. They’re ideal for organizing internal wiring in dashboards, appliances, or control panels, where accessibility and ease of installation are priorities.

Environmental Factors

Cable assemblies are built to withstand exposure to harsh elements. The outer sheath shields the internal wires from moisture, chemicals, UV rays, and abrasion, making them ideal for outdoor, mobile, or high-vibration environments.

Wire harnesses, on the other hand, are better suited for dry, protected areas. Because the individual wires are only grouped together with minimal covering, they lack the same level of environmental resistance and are typically used where external shielding isn’t necessary.

Cost Considerations

Wire harnesses are generally more cost-effective due to their simpler construction and fewer materials. While initial costs are lower, it’s important to consider the total cost of ownership, especially in systems exposed to wear and tear. They require less labor and are quicker to produce, making them a practical choice for high-volume applications in stable environments.

Cable assemblies tend to have a higher upfront cost because of the added materials, design requirements, and protective features. However, in applications where exposure or durability is a factor, the investment can lead to reduced maintenance and longer service life.

Design and Complexity

Cable assemblies are often engineered for complex systems that require precise routing, shielding, and protection. They support custom configurations, including molded connectors, multi-conductor layouts, and overmolding for strain relief, making them ideal for specialized equipment.

Wire harnesses are typically simpler, designed to organize and manage basic electrical pathways. While they can be customized to fit a specific layout, they don’t offer the same level of shielding or structural integration as a cable assembly.

When to Use a Cable Assembly vs a Wire Harness

A cable assembly is the better choice when:

- The environment involves moisture, chemicals, or temperature extremes.

- Movement or vibration could damage exposed wires.

- Shielding from electrical noise or interference is required.

- A compact, protected solution is needed for complex layouts.

A wire harness is ideal when:

- The wiring is installed in a clean, enclosed space.

- Weight, flexibility, or installation speed is a factor.

- Easy access to individual wires is necessary for maintenance or adjustments.

- Cost control is important, and performance demands are moderate.

Kato Cable: Your Partner for Custom Interconnect Solutions

At Kato Cable, we specialize in manufacturing high-performance cable assemblies and wire harnesses tailored to the needs of OEMs in the automotive, electronics, and industrial equipment industries. Whether your application calls for the protection of a sealed assembly or the efficiency of a wire harness, our team works closely with you to develop a solution that fits your system and meets your specifications.

Located in Mankato, Minnesota, we bring decades of experience, advanced capabilities, and a strong commitment to quality to every project. As a strategic partner, we help you make informed decisions that impact performance, reliability, and cost.

Ready to take the next step? Request a quote or connect with us on LinkedIn or Facebook.