An Expert Guide to Electrical Control Panel Assembly

Share Article:

Control panel assembly plays a direct role in the performance and safety of OEM equipment. Every connection, enclosure, and configuration has a purpose. When the wiring is precise and the layout is engineered to spec, systems operate reliably under pressure.

OEMs in

industries like industrial machinery rely on these

assemblies to maintain quality, meet regulatory standards, and reduce field failures. Poor execution can lead to delays, troubleshooting, and long-term maintenance issues.

Experienced manufacturers like Kato Cable help OEMs meet electrical and mechanical requirements while keeping production on track.

Why Control Panel Assembly Matters for OEMs

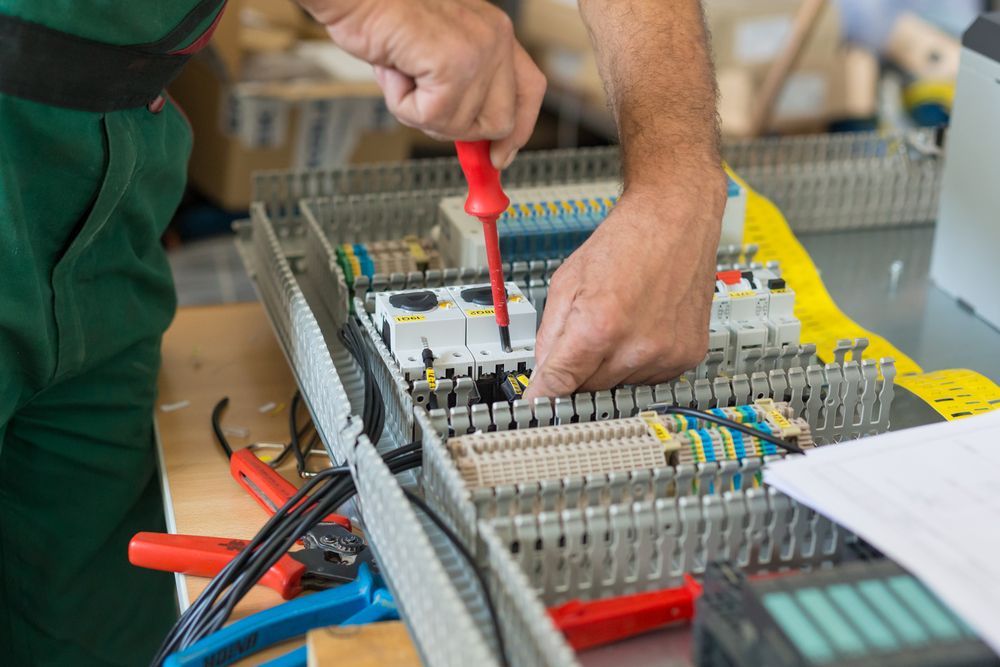

Control panels coordinate and manage electrical functions across complex systems. They house components like circuit breakers, relays, PLCs, terminal blocks, and wiring, all configured to meet specific equipment needs. For OEMs, these assemblies are not just part of the build. They directly affect how equipment performs under real-world conditions.

A well-designed panel protects electrical systems, improves serviceability, and reduces the risk of failure. It also helps meet regulatory and safety requirements. These outcomes carry weight in industries where downtime can lead to operational losses or safety concerns.

OEMs need a control panel assembly that matches their performance standards, installation methods, and production schedules. When panels are built to spec and delivered ready for integration, internal teams can stay focused on delivering complete systems.

The Common Challenges OEMs Face

OEMs often run into delays, cost overruns, and technical issues during control panel assembly. These problems usually trace back to miscommunication, inconsistent quality, or a lack of specialized expertise. Some of the most common challenges include:

Incomplete or inaccurate documentation: Missing wire lists, unclear schematics, or outdated drawings lead to mistakes during production.

Inconsistent component sourcing: When parts are backordered or substituted without proper review, it can compromise panel performance or delay delivery.

Limited capacity during production spikes: Tight timelines and shifting priorities can overwhelm internal teams or underprepared suppliers.

Quality issues during installation: Panels that don’t align with mounting specs or enclosure requirements often require rework in the field.

Lack of standardization: Inconsistent builds from one panel to the next make troubleshooting and scaling more difficult over time.

OEMs that face these challenges repeatedly risk delays, budget pressures, and added strain on engineering and operations teams. Reducing those risks starts with selecting the right manufacturing partner.

How the Right Partner Simplifies Control Panel Assembly

A capable manufacturing partner helps reduce delays, protect quality, and keep programs on track. They understand how to translate electrical and mechanical requirements into accurate, repeatable builds that meet performance expectations.

At the start of a project, they review schematics and layouts to confirm clarity and consistency. Throughout production, they follow documented processes that align with approved specifications. If sourcing issues come up, they manage lead times and substitutions without compromising quality or timelines.

They also handle functional testing and inspection before shipment, so panels arrive ready for integration. This approach limits rework, improves installation consistency, and helps internal teams stay focused on final assembly and delivery.

Kato Cable’s Approach to Control Panel Assembly

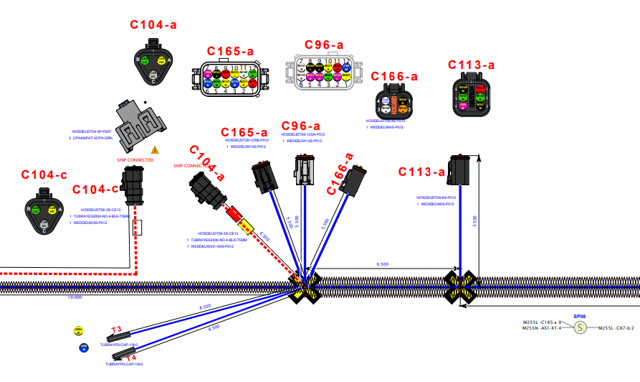

Kato Cable builds every control panel to meet the specific needs of the OEM and the equipment it powers. Projects begin with a review of all technical documentation, including wiring diagrams, layout drawings, and a detailed Bill of Materials (BOM). Their team works directly with engineers to clarify details, address potential issues, and align on build expectations before production begins.

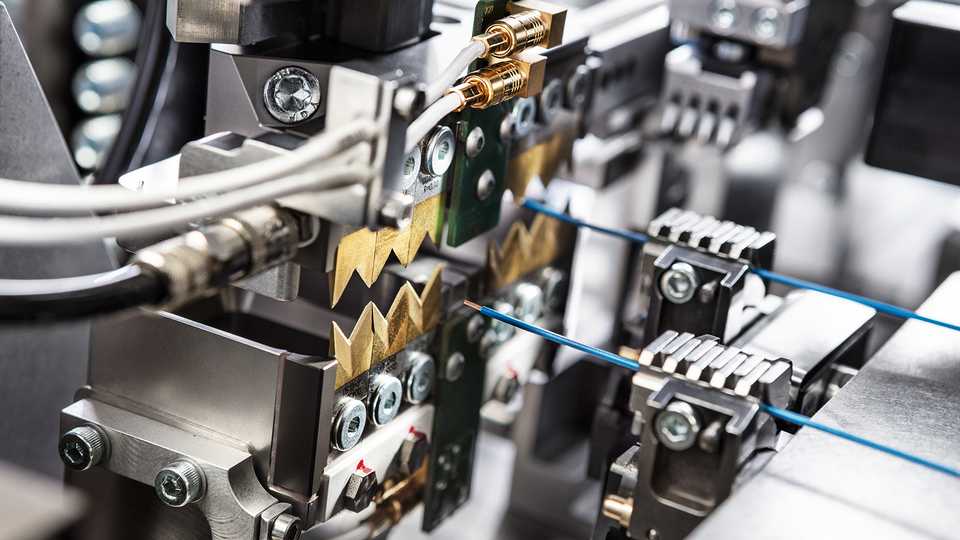

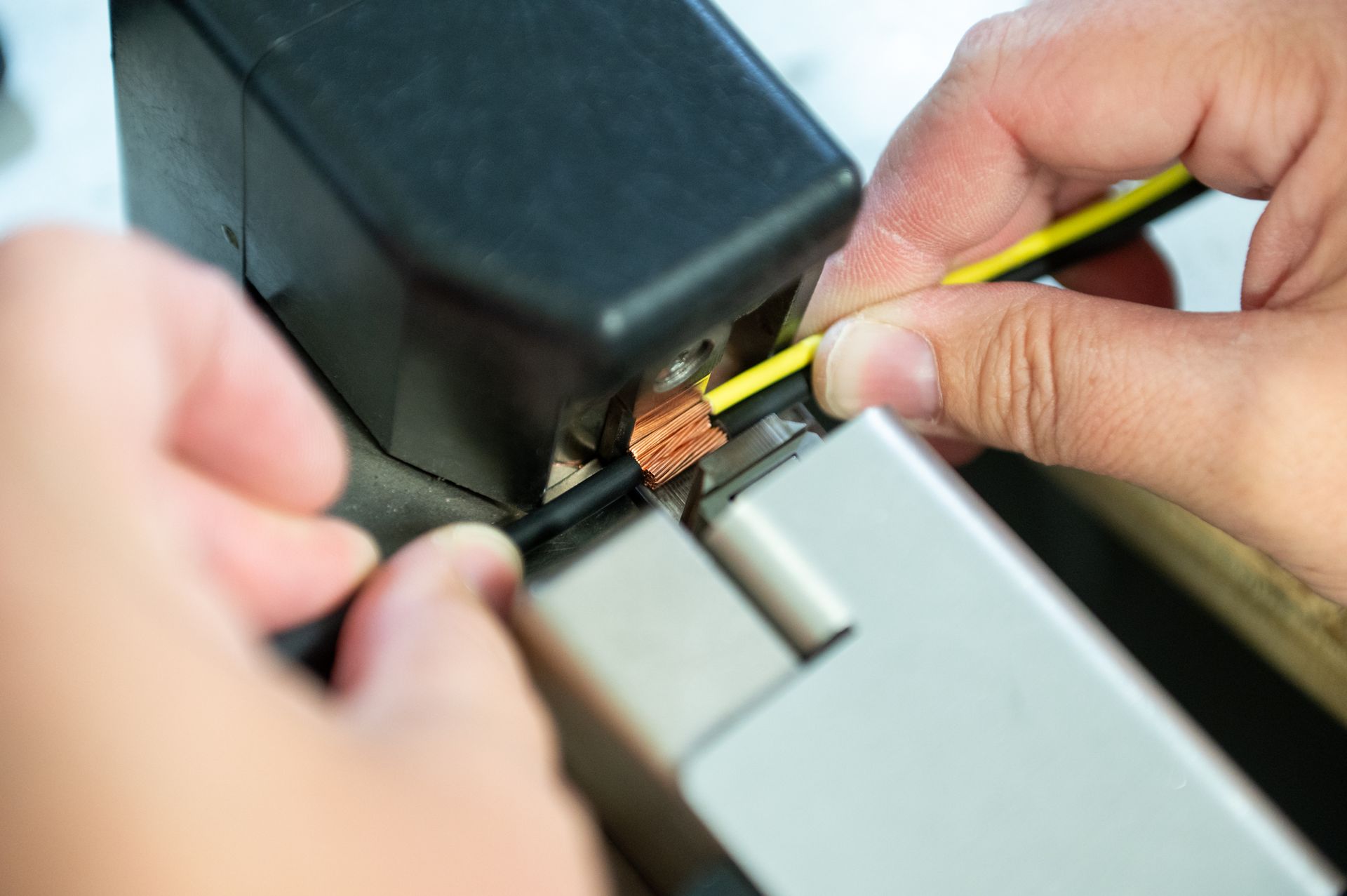

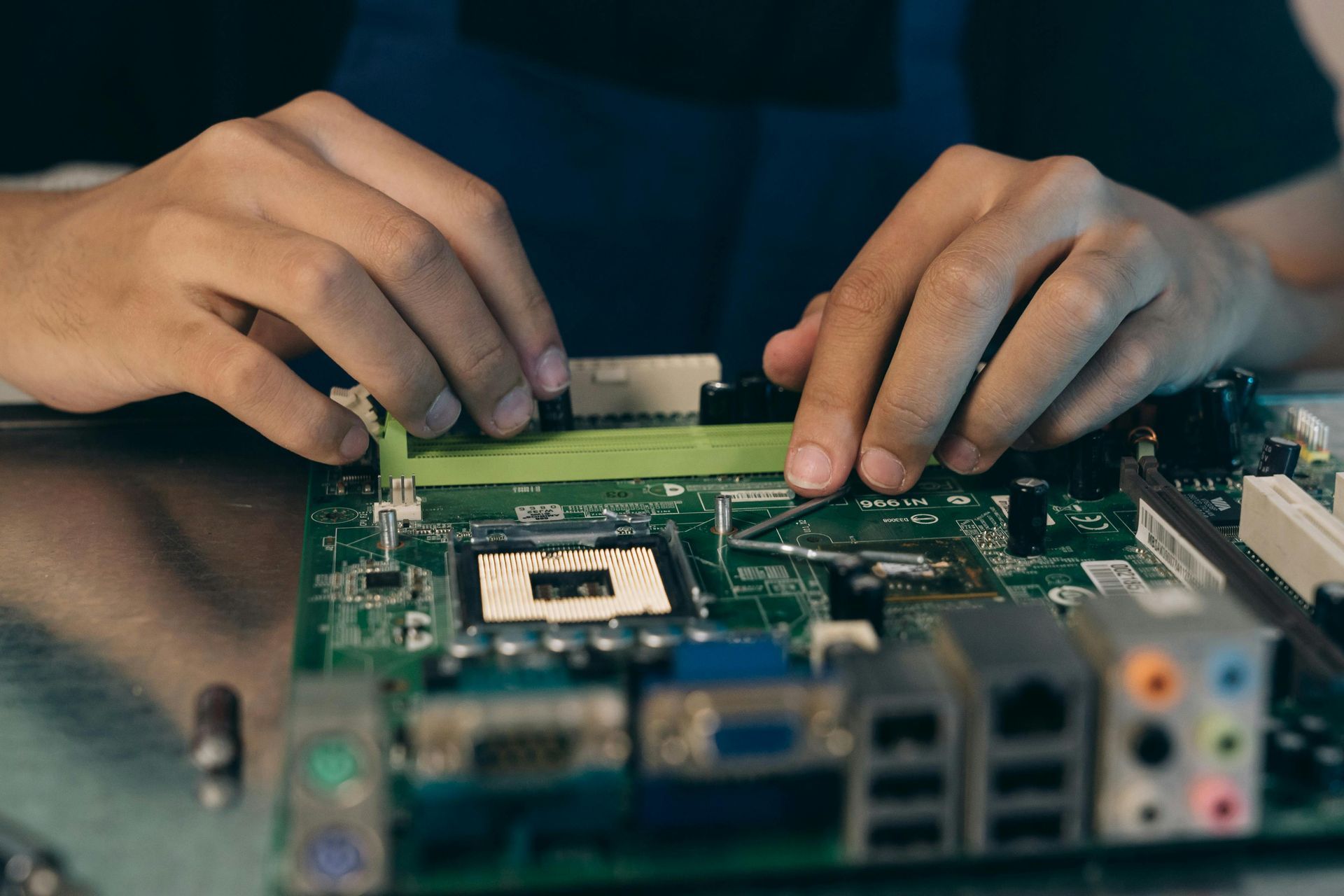

Assembly takes place in a controlled environment using documented procedures and industry-standard tools. Technicians follow work instructions tailored to each panel, which helps maintain consistency across orders and build cycles. Panels are tested for continuity, proper labeling, wire routing, and component fit to confirm they meet exact requirements.

Kato Cable also brings discipline to sourcing and material planning. Approved components are stocked, tracked, and verified ahead of each build to avoid supply-related disruptions. Throughout the process, OEMs have access to regular status updates, clear documentation, and direct communication.

Every panel reflects the level of care put into the build. Wire routing

is clean, labeling is precise, and quality stays consistent from unit to unit.

Steps to Get Started with Kato Cable

The onboarding process is structured to keep projects organized, timelines realistic, and communication clear from the beginning.

1. Share your project details

Provide your wiring diagrams, layout drawings, and BOMs. These documents give the team what they need to understand scope, materials, and technical requirements.

2. Technical review

Each project is reviewed to confirm specifications are complete and feasible. Any gaps or questions are addressed before moving forward.

3. Receive a quote

You’ll receive a detailed quote that includes pricing, tooling, lead time, and any sourcing considerations that could affect scheduling.

4. Approve and schedule

Once approved, and the PO is received, your project enters the production queue. Timelines are confirmed based on material availability and current capacity.

5. Track progress

Updates are provided during production. Any changes or adjustments are communicated quickly, so there are no surprises.

Request a Quote for Reliable Control Panel Assembly

Reliable control panel assembly starts with a partner who understands the technical and production pressures OEMs face. Kato Cable delivers consistent results through clear communication, accurate execution, and attention to detail at every stage.

To request a quote,

reach out to their team with your project requirements. For updates and insights, connect on LinkedIn or Facebook.