Why Wire Harness Design Impacts Product Reliability

Share Article:

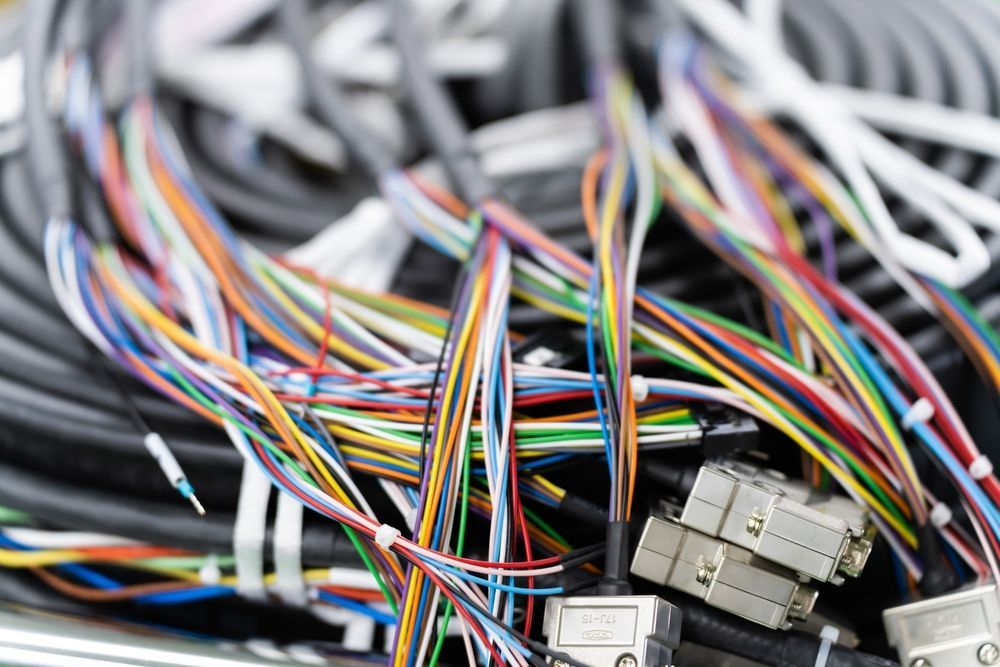

The body content of your post goes here. To edit this text, click on it and delete this default text and start typing your own or paste your own from a different source. Wire harnesses act as the electrical foundation of complex systems. In vehicles, industrial machinery, and equipment panels, they connect power and signals to every key component. When the design falls short, product performance, safety, and lifespan are at risk. A well-planned electrical wire harness design reduces failure points, simplifies assembly, and helps maintain system integrity under real-world conditions.

Understanding Wire Harness Design

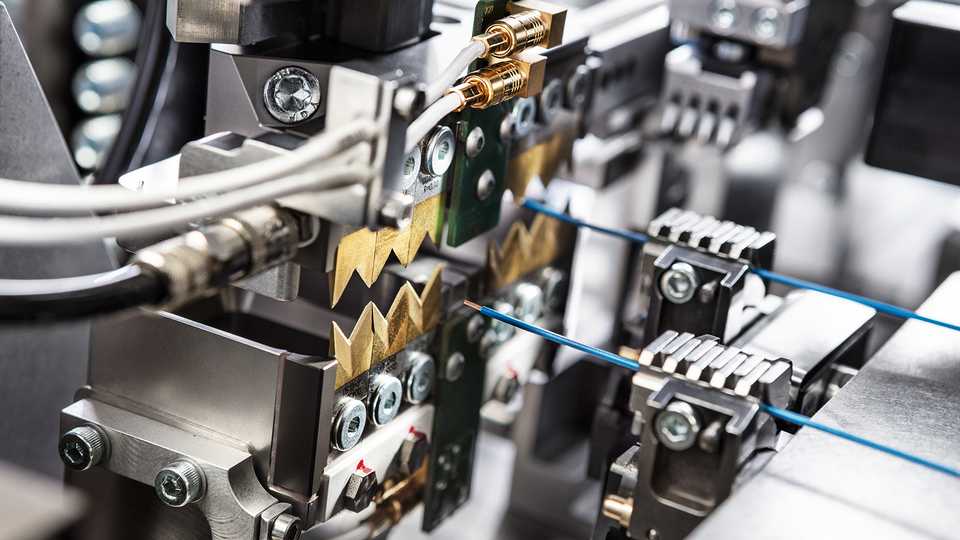

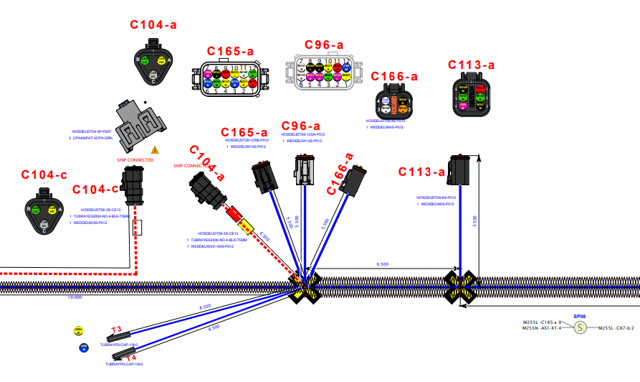

Wire harness design shapes how power and signals move through a system. It brings together routing paths, connector types, shielding needs, and environmental constraints. Every detail, including bend radius and mounting method, affects performance under load, vibration, and temperature changes.

A dependable electrical wire harness design supports consistent function, easier maintenance, and longer service life. Getting the design right reduces stress on wires and connectors, cuts the risk of electrical faults, and keeps systems running as intended.

The Cost of Poor Wire Harness Design

Weak wire harness design can lead to performance issues that appear early and compound over time. Loose connections, incorrect routing, and inadequate protection can cause short circuits, voltage drops, and signal interference. These failures are difficult to trace once a product is in the field and often result in costly repairs or unplanned downtime.

Design flaws can also slow assembly and increase the chance of human error during installation. When harnesses are hard to fit, label, or secure, teams spend more time correcting problems instead of moving forward. For OEMs, this can delay production, increase labor costs, and damage product reliability.

Key Principles of Reliable Wire Harness Design

Reliable wire harness design starts with clarity. Each part of the system should be built for the environment it will face, the loads it will carry, and the space it fits into. That means careful attention to materials, layout, protection, and labeling.

When these elements work together, the result is a harness that installs cleanly, performs consistently, and lasts longer in the field.

Material Selection and Environmental Considerations

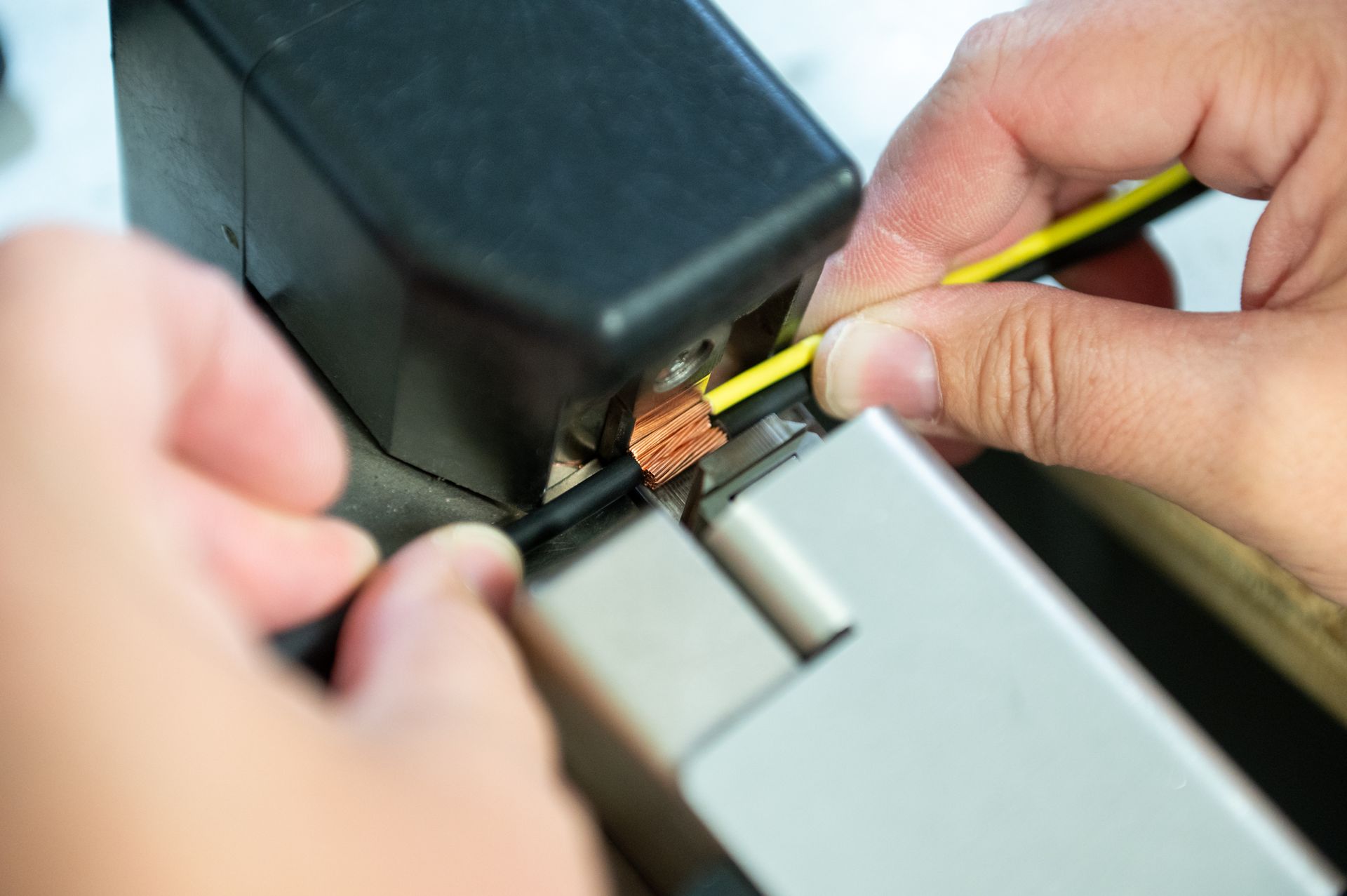

Wire harness performance depends heavily on material quality and compatibility. Conductors, insulation, and connectors must match the electrical load and resist the conditions they’ll face in use. Exposure to moisture, oil, vibration, or extreme temperatures can wear down components quickly if materials are poorly matched.

Choosing the right insulation and jacketing helps prevent cracking, abrasion, and thermal breakdown. Corrosion-resistant terminals and seals reduce failure points in wet or high-humidity environments. These choices directly affect how well the harness holds up over time and how reliably it supports the system it powers.

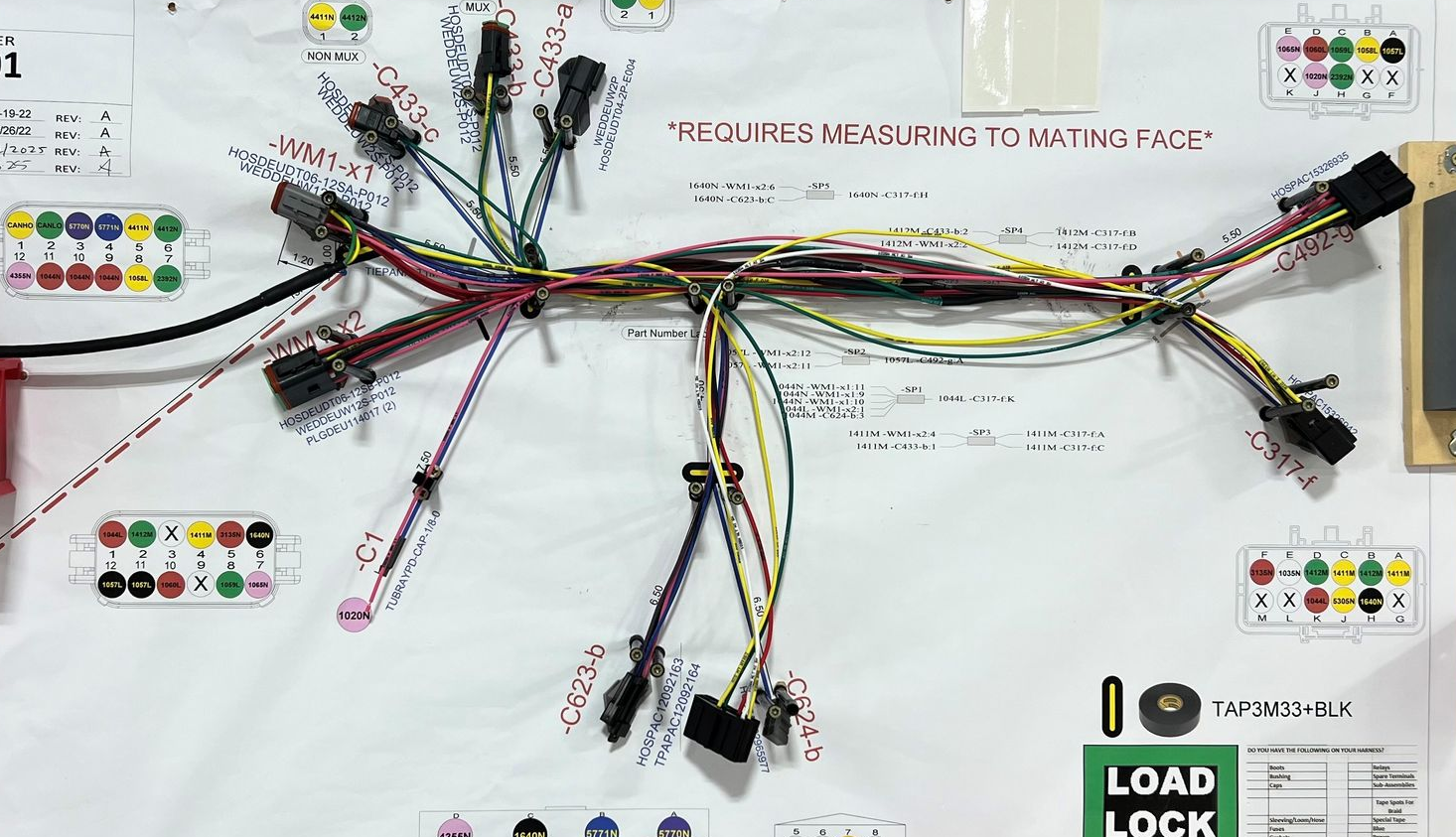

Precision in Layout, Routing, and Labeling

A well-planned layout reduces strain on wires and connectors, lowers the risk of interference, and simplifies installation. Routing paths should avoid sharp edges, tight bends, and areas of high movement or heat. Proper spacing helps manage airflow and supports consistent performance across the system.

Clear labeling and logical connector placement speed up assembly and reduce wiring errors. When harnesses are easy to identify and connect, teams spend less time troubleshooting and more time moving forward. These details help maintain quality through every stage of production and service.

Testing and Validation for Performance Assurance

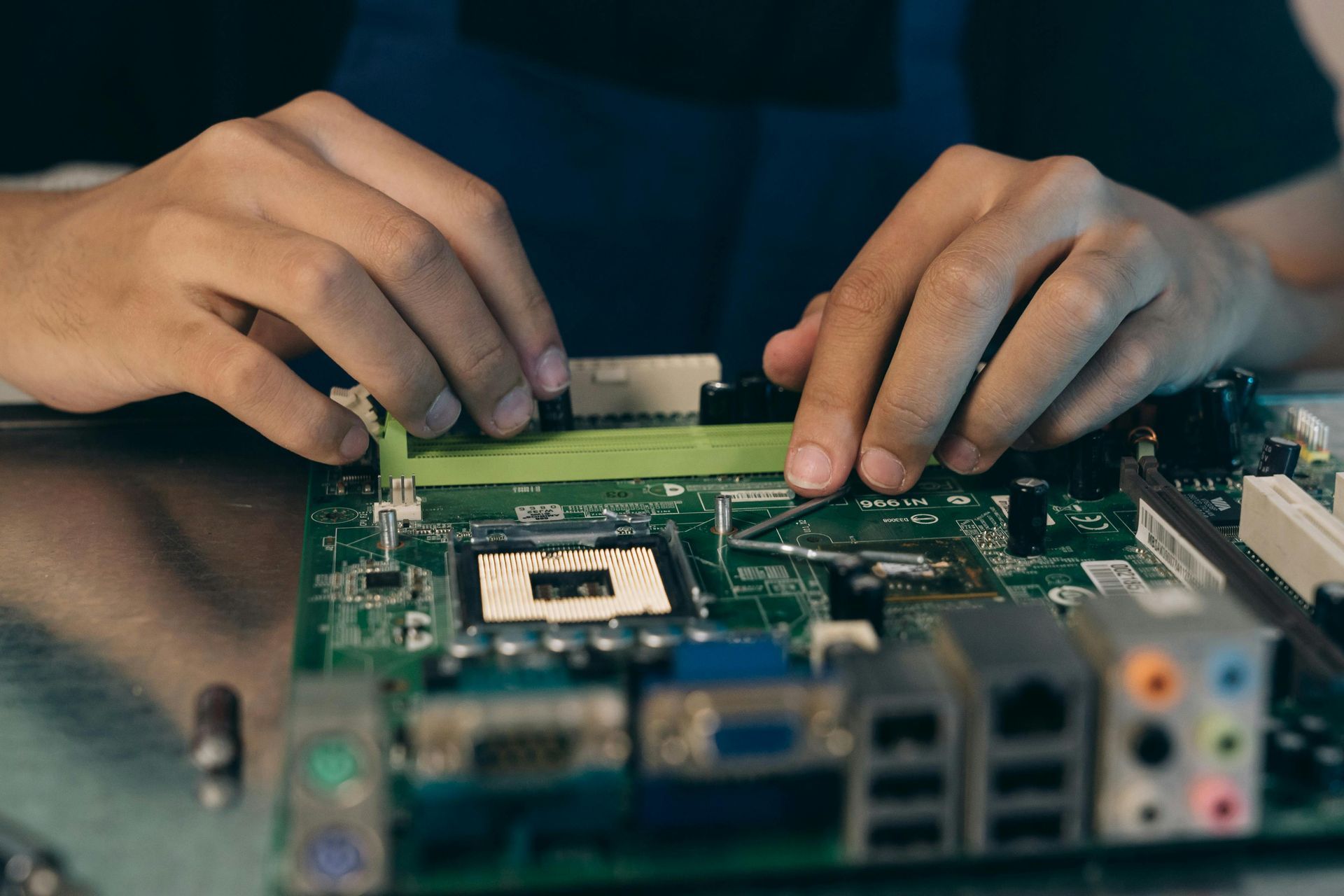

Thorough testing confirms that a wire harness will perform as expected under real-world conditions. Electrical tests check for continuity, resistance, and insulation integrity. Mechanical checks verify fit, retention, and durability under stress or vibration.

Validation also helps catch design flaws before production scales. Dimensional checks, pull testing, and environmental cycling reveal weak points that could lead to failure in the field. A harness that passes these tests is more likely to hold up over time and perform reliably in its intended application.

Designing for Long-Term Reliability and Performance

Reliability starts at the design stage and carries through to every connection, clamp, and routed path. Harnesses that last are built to handle mechanical stress, thermal cycling, and environmental exposure without degrading. Attention to bend radius, strain relief, and secure mounting helps prevent fatigue and failure over time.

Good design also considers serviceability. When wires are accessible and clearly labeled, repairs and replacements are faster and less prone to error. These factors reduce downtime, extend product life, and improve performance in the field.

How OEMs Gain from Expert Harness Design

A well-executed wire harness design can speed up production, reduce field failures, and simplify compliance. OEMs that prioritize quality in the design phase benefit from fewer warranty claims, lower rework rates, and faster assembly times.

Partnering with experienced engineers adds value beyond the harness itself. Early input helps avoid compatibility issues, reduces back-and-forth during prototyping, and leads to a cleaner, more efficient final build.

Partner with Kato Cable for Proven Reliability

Product reliability begins at the harness level. At Kato Cable, every design decision is backed by experience, engineering insight, and a focus on long-term performance. We work closely with OEMs across industries to develop wire harnesses that match application needs, simplify installation, and hold up under real-world conditions.

Our approach combines collaborative design, careful material selection, and proven validation processes. The result is a harness that performs consistently over time and helps reduce downtime, rework, and service calls.

If you’re looking for a partner who understands the impact of wire harness design on product quality, we’re ready to help. Request a quote or

contact Kato Cable to get started.