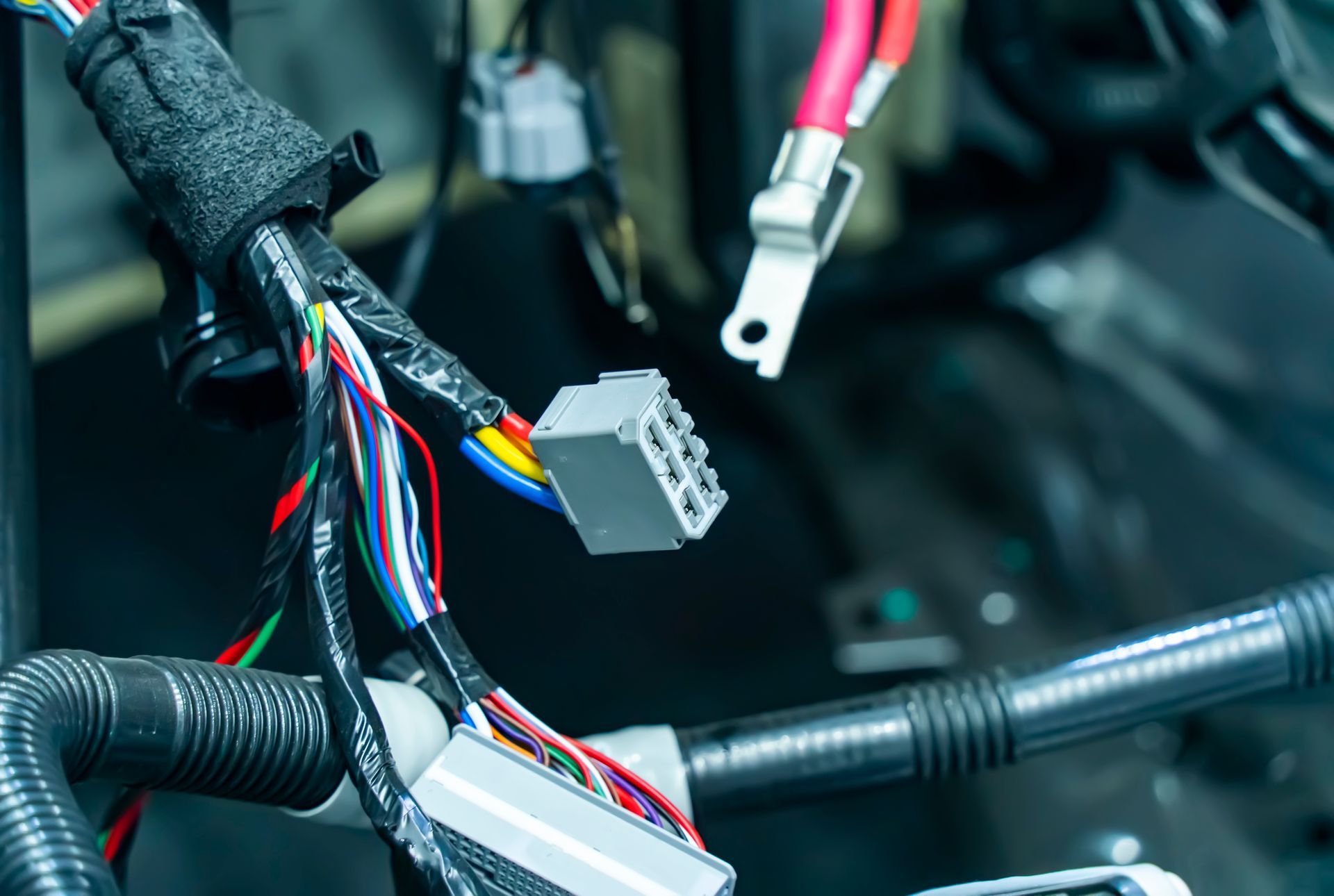

Commercial Vehicle Wiring Harnesses and Cable Assemblies

Reliable Harnesses for Heavy-Duty Vehicles

Durability, reliability and safety are ever important when you consider mobile vehicles such as Fire Trucks, Cement Mixers, Waste Management and Excavators. Downtime due to a faulty harness is not an option in these markets. Kato Cable’s harnesses range from high-volume applications to the most complex harness with hundreds of connectors and terminals produced to exacting specifications.

What Is a Commercial Vehicle Cable Assembly?

A commercial vehicle cable assembly is a bundled system of electrical conductors encased in a protective jacket, used to transmit power, signals, or control data throughout work trucks, buses, emergency vehicles, and other heavy-duty platforms. These assemblies connect systems such as lighting, power distribution, engine control, and safety equipment.

Designed for rugged, high-vibration environments, commercial vehicle cable assemblies must stand up to constant use, exposure to the elements, and demanding operating cycles. Their construction helps maintain system performance and vehicle uptime in both on-road and off-road applications.

Automobile Design Wire Harness - How it works

In commercial vehicles, a wire harness acts as a structured system of wires and connectors, organizing and transmitting electrical power and signals between various components, ensuring efficient and reliable operation of the vehicle's systems.

What it is:

A wire harness is a bundle of wires, cables, and connectors designed to transmit electrical signals and power within a vehicle.

Function:

It organizes and routes the numerous wires needed to connect different electrical components, like the engine, braking system, lights, and safety systems.

Custom Design:

Wiring harnesses are often custom-designed for specific vehicle models and applications, ensuring optimal performance and fit.

Importance in Commercial Vehicles:

In commercial vehicles, where electrical systems are often complex and critical for operation, a reliable and well-designed wiring harness is essential for ensuring the vehicle's safe and efficient operation.

Benefits

Enhanced Durability and Reliability:

Vehicles like garbage trucks and emergency vehicles operate under demanding conditions. Wire harnesses are built to withstand vibrations, extreme weather, moisture, and physical stresses. They ensure that electrical systems remain operational under tough working conditions.

Simplified Installation and Maintenance:

Wire harnesses allow for faster and more organized installation of electrical components, such as lights, sirens, radios, and hydraulic systems. A well-designed harness reduces installation time and makes maintenance easier by providing clear and manageable wiring.

Vibration Resistance:

Vehicles like garbage trucks and emergency vehicles often face constant vibrations from heavy-duty operations. Wire harnesses are engineered to absorb vibrations and prevent wires from loosening or fraying over time, ensuring the electrical systems remain secure.

Space Optimization:

Specialized vehicles often have limited space to accommodate all the electrical components needed. Wire harnesses provide a compact, organized way to route multiple wires, freeing up space and ensuring a tidy, efficient electrical layout.

Reduced Risk of Damage:

By consolidating wires into a single organized bundle, wire harnesses reduce the likelihood of abrasion, wear, and accidental damage. This protection ensures that wiring stays intact even in environments with heavy movement or contact with debris.

Improved Aesthetics

and Organization:

By grouping wires together and keeping them organized, wire harnesses reduce visual clutter in the vehicle. This makes it easier to inspect, repair, and upgrade electrical systems without the mess of loose or tangled wires.

Safety and Compliance:

Mobile vehicles like emergency vehicles require high safety standards. Wire harnesses are designed to ensure that all electrical connections are secure and meet relevant safety regulations, minimizing the risk of electrical failures during critical operations.

Examples of Applications

Garbage Trucks:

- Application: Wire harnesses in garbage trucks manage the electrical systems that control hydraulics for lifting bins, compacting waste, controlling lighting, and powering onboard cameras or GPS systems.

- Why: These trucks operate in demanding conditions, including frequent stops, vibrations, exposure to dirt, and moisture. Wire harnesses ensure the electrical components remain reliable and protected under these circumstances.

Service Vehicles (Utility Trucks, Tow Trucks):

- Application: Service vehicles use wire harnesses for powering lighting, emergency beacons, hydraulic equipment (like cranes), and communication systems.

- Why: These vehicles are often used in the field for extended hours, requiring their electrical systems to be durable, secure, and easy to maintain. Wire harnesses help ensure the longevity and functionality of their electrical components.

Emergency Vehicles (Ambulances, Fire Trucks, Police Vehicles):

- Application: Wire harnesses are used to control the lighting systems (sirens, emergency lights, flashers), communication equipment (radios, GPS), and specialized equipment (defibrillators, pumps, etc.).

- Why: Emergency vehicles need immediate reliability in critical situations. The wire harness ensures that emergency systems are operational at all times, even under high-stress conditions.

Refrigerated Delivery Trucks:

- Application: In refrigerated trucks, wire harnesses connect the refrigeration system, cargo lights, temperature monitoring systems, and power systems for refrigeration units.

- Why: The harsh conditions of refrigerated trucks (extreme cold, moisture, and heavy vibrations) require specialized wire harnesses to ensure the cooling system and other electrical components function without failure.

Construction and Landscaping Vehicles:

- Application: These vehicles use wire harnesses to control heavy-duty equipment, lighting, and sensors used in construction and landscaping work.

- Why: These vehicles operate in extreme cold and harsh conditions. Wire harnesses must be able to resist freezing temperatures, moisture, and the vibrations that come with heavy snow removal equipment.

OEM Support for Commercial Vehicle Cable Design

Commercial vehicle platforms often involve complex electrical systems with tight packaging and high functional demands. Kato Cable collaborates with OEMs to design wire harnesses and cable assemblies that meet electrical, environmental, and regulatory requirements across a wide range of vehicle types.

We assist with component selection, routing layouts, and design for manufacturability to support efficient

assembly and long-term durability. Our team helps you meet critical timelines while minimizing installation challenges and electrical faults in the field.

Process Control & Engineering Control Services

Process Control

Precision and consistency are at the heart of every custom cable solution. Our Process Control strategies ensure each assembly meets exact specifications, from initial concept to final production. Through rigorous quality checks, standardized procedures, and real-time monitoring, we optimize efficiency while maintaining the highest level of reliability.

Engineering Control

From concept to completion, Engineering Control ensures every design is optimized for functionality, manufacturability, and long-term performance. Our expert team evaluates form, fit, and function, applies industry best practices and testing protocols, and leverages innovative solutions to deliver high-quality and cost-effective cable and harness assemblies.

Why OEMs Trust Kato Cable for Interconnect Solutions

Manufacturers of commercial vehicles depend on electrical systems that perform under load, in motion, and across varying climates. Kato Cable delivers assemblies that meet these demands with precision and consistency.

OEMs trust us to help streamline production, reduce field failures, and meet evolving system requirements without delays. Our industry knowledge, hands-on design support, and dependable turnaround times make us a reliable partner throughout the vehicle development cycle.

Our Products are Proudly Made in the USA

The Kato Cable Advantage

The Kato Cable Advantage is a holistic approach to looking at the value that you bring to your customers, employees and community. Our customers relate directly to our responsiveness and engineering value, to the investments that we have made into efficiencies and automation, and to the key metrics of industry leading Quality and On Time Delivery. Our employees relate to a sense of inclusion, an appreciation and value to feedback, and the philosophy of making improvements every day. Our community relates to our growth and volunteerism and leadership that we strive for in our region. Together these attributes and values truly deliver the Kato Cable Advantage!

Quality & Reliability

Delivering precision-engineered wire harnesses, cable assemblies, and electro-mechanical assemblies that meet the highest industry standards.

Innovation

Continuously improving processes and technologies to provide cutting-edge solutions for diverse industries.

Customer Commitment

Building strong partnerships through collaboration, responsiveness, and tailored solutions.

Your Industry, Our Vision

Our Certifications

Stay Connected with our Blog

Mobile Vehicle Contact Us

We will get back to you as soon as possible.

Oops, there was an error sending your message. Please try again later.

Looking for Support?

Our team is here to help. Whether you’re looking for a custom solution or need support with an existing project, we’re just a message away. Reach out today, and let’s find the right solution for you.