Optimizing Wire Harness Design for Harsh Environments

Share Article:

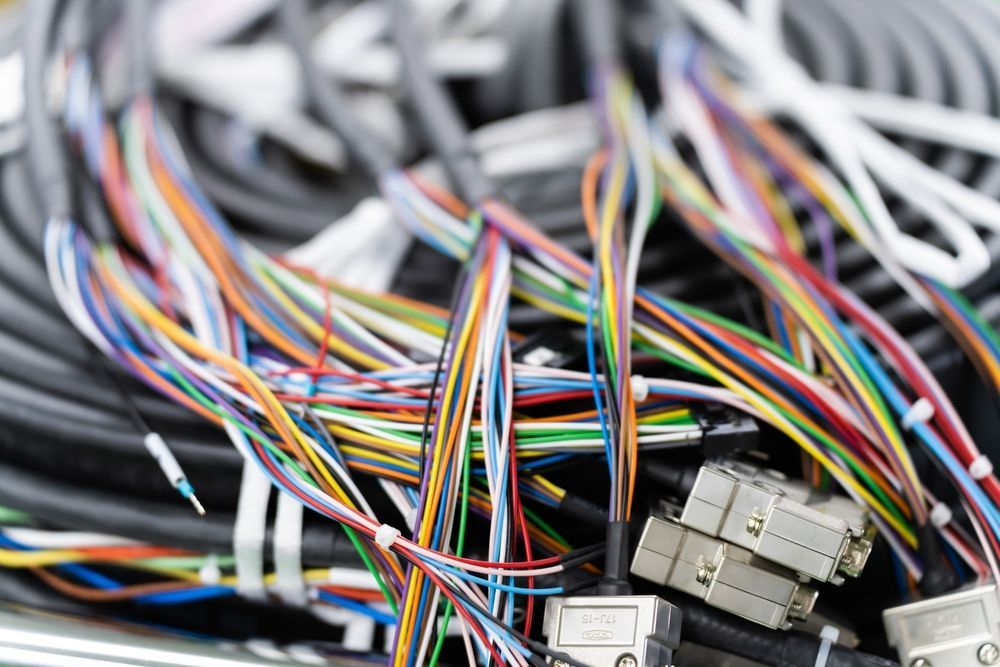

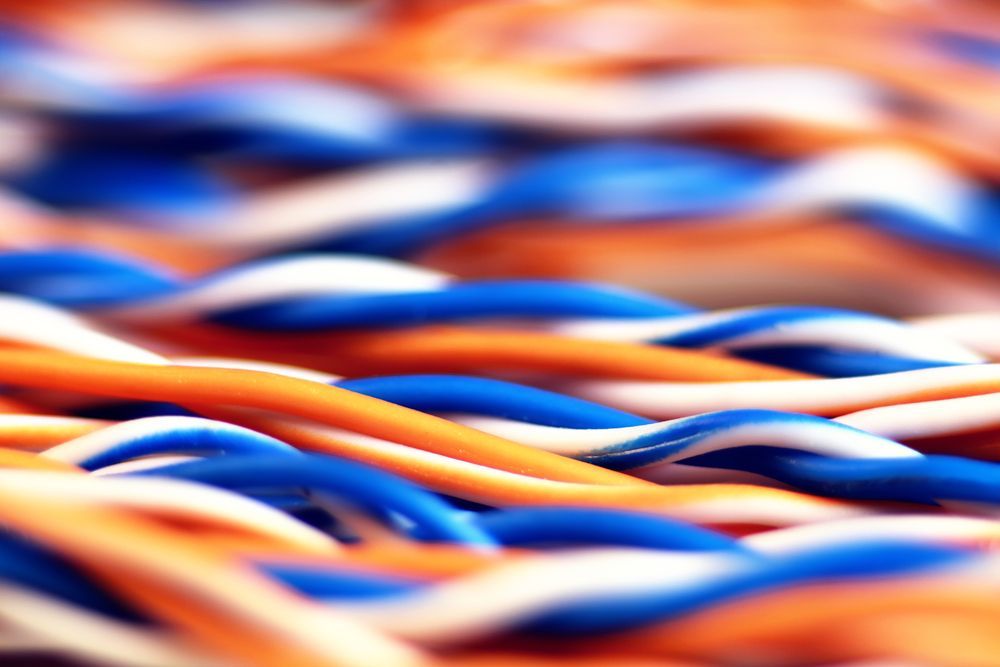

Equipment used in construction, agriculture, defense, and industrial manufacturing doesn’t operate in controlled conditions. It’s exposed to vibration, moisture, heat, cold, dust, and chemicals. In these settings, a standard wire harness won’t last. It takes a design built for the environment to deliver consistent power and signal without failure.

Wire harness design for harsh environments focuses on durability, insulation integrity, and protection against mechanical and environmental stress. When engineered correctly, a harsh environment wire harness can improve uptime, reduce maintenance, and extend the life of the entire system.

Why Harsh Environments Demand Superior Wire Harness Design

Heat, abrasion, water ingress, and chemical exposure can all compromise cable performance. In harsh environments, failure isn’t just inconvenient. It can lead to safety issues, system downtime, or permanent equipment damage. Wire harnesses that aren’t built to handle extreme conditions are more likely to crack, short, or corrode under stress.

A well-engineered design accounts for these risks from the start. It uses materials, routing strategies, and sealing methods that reduce wear and protect connections. Choosing the right approach up front helps prevent field failures and avoids costly rework or redesign later in the production cycle.

Understanding What Defines a Harsh Environment

A harsh environment isn’t limited to a single type of exposure. It’s any setting where the wire harness faces physical, chemical, or environmental stress that can reduce performance over time. This includes:

- High vibration from engines, pumps, or heavy machinery

- Wide temperature swings, including freezing or sustained heat

- Moisture and humidity, especially in outdoor or marine applications

- Dust, dirt, and debris that can clog or wear down insulation

- Exposure to oil, fuel, solvents, or corrosive chemicals

Each application brings its own mix of challenges. Designing for harsh environments means understanding the full range of conditions the harness will face over its service life.

Key Factors in Designing Wire Harnesses for Durability

Harsh conditions expose weak points in cable assemblies. Designing for durability means making smart choices at every stage, starting with the basics and building in protection where it's needed most.

Important factors include:

Material selection:

Wire insulation and jacketing must handle temperature extremes, fluid exposure, and abrasion. Thermoplastic elastomers, cross-linked polyethylene, and fluoropolymers offer better performance than standard materials.

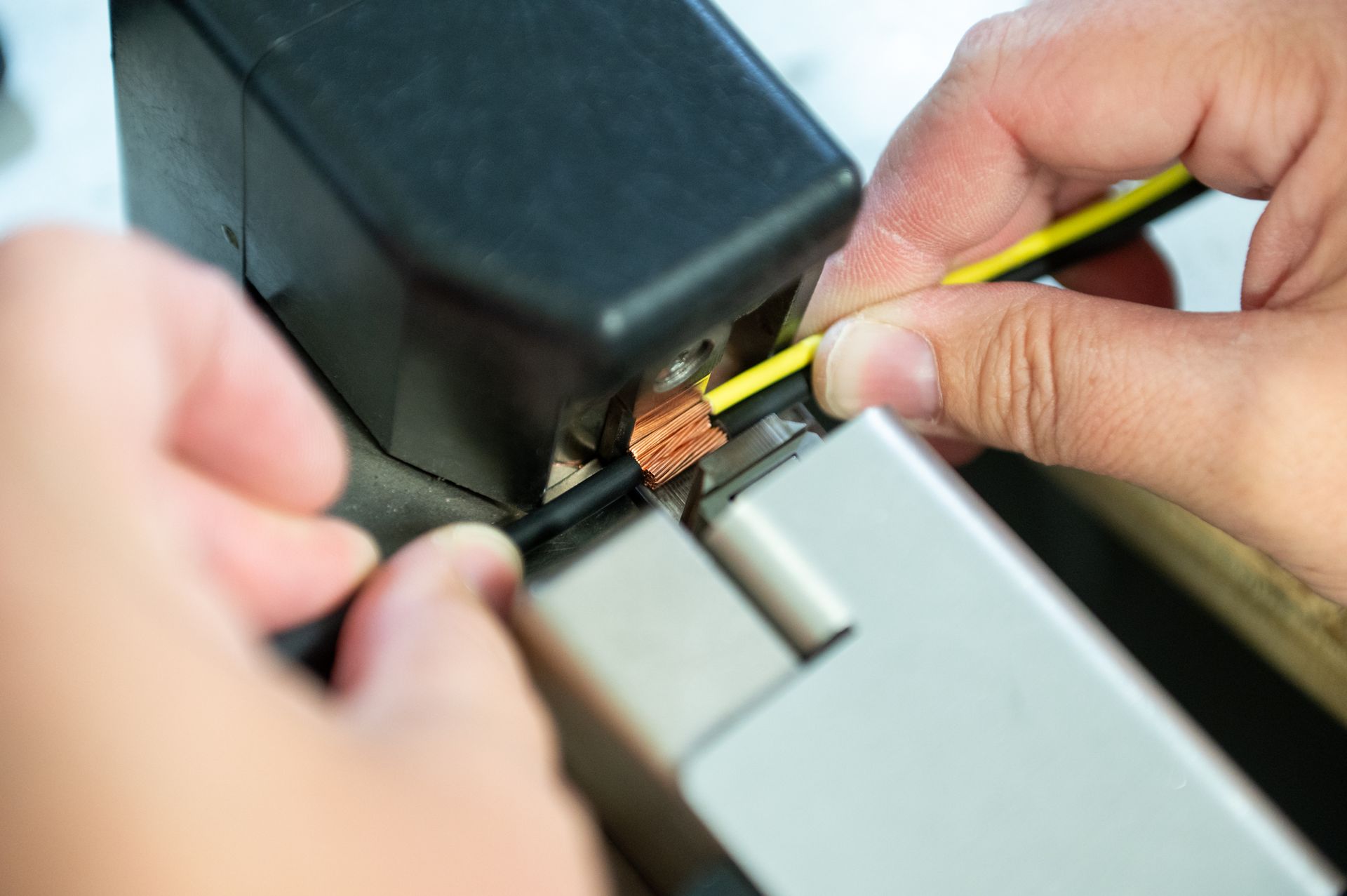

Sealing and strain relief:

Grommets, boots, and heat shrink tubing help keep out moisture and debris while protecting terminals and crimps from movement.

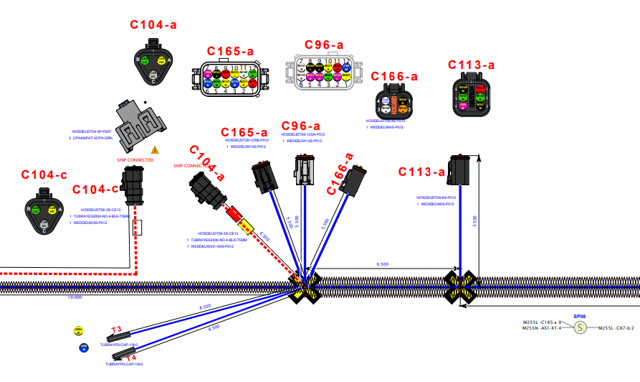

Routing and mounting:

Cables should be positioned to avoid sharp edges, friction, or excessive flexing. Secure mounting reduces wear caused by vibration.

Connector selection:

Use sealed connectors rated for moisture, dust, and chemical resistance. Designs with positive locking mechanisms and backshells provide better long-term reliability.

Common Design Mistakes That Reduce Harness Reliability

Even small oversights in design can lead to large problems once the harness is in use. Failures in harsh environments are rarely caused by a single issue. More often, they result from a combination of weak points that could have been addressed earlier in the process.

Avoidable mistakes include:

Underrated materials:

Using insulation or jacketing not suited for the environment can lead to cracking, melting, or chemical breakdown.

Overlooking strain relief:

Without proper support at connection points, wires can pull loose or wear out from vibration.

Improper routing:

Routed too close to heat sources or sharp surfaces, cables wear faster and are more likely to fail.

Weak sealing methods:

Poor sealing allows moisture and debris to reach conductors, increasing the chance of shorts or corrosion.

Inconsistent testing:

Skipping key tests or relying on outdated procedures can allow hidden defects to pass through production.

Identifying and correcting these design gaps early helps prevent performance issues and unplanned downtime later.

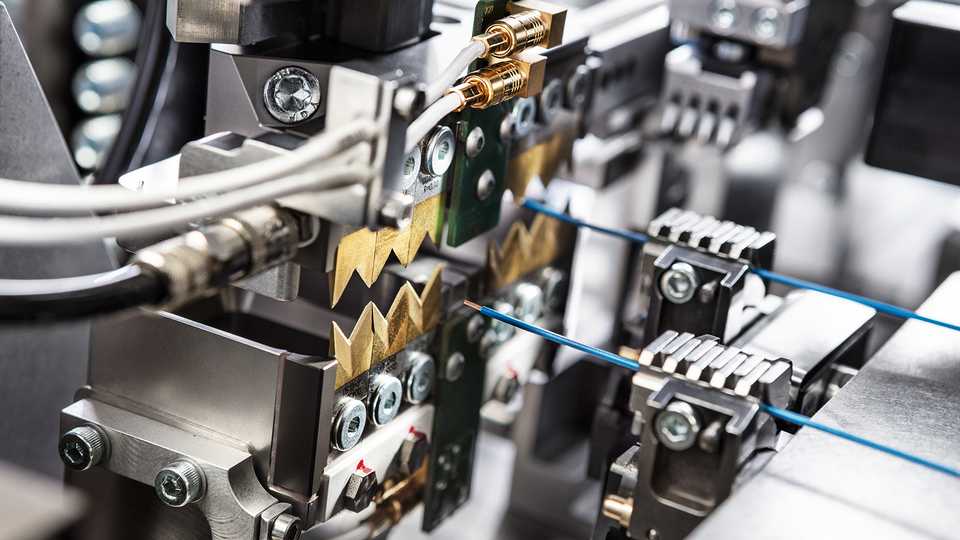

Proven Testing Methods for Harsh Environment Wire Harnesses

Design alone isn’t enough. Every harsh environment wire harness must be verified through testing that reflects real-world conditions. This step confirms that the assembly will hold up under the physical and electrical demands of its application.

Common test methods include:

Continuity and insulation resistance testing:

Confirms that circuits are complete and that insulation prevents unwanted current flow.

High-potential (hipot) testing:

Applies a controlled voltage to identify breakdowns in insulation.

Thermal cycling:

Exposes the harness to alternating hot and cold temperatures to simulate field conditions.

Vibration testing:

Replicates the impact of continuous movement and mechanical stress during use.

Ingress protection (IP) testing:

Validates the sealing of connectors and boots against dust and moisture.

How Kato Cable Engineers for Reliability and Performance

Kato Cable approaches every project with a focus on application-specific design. Our team evaluates environmental challenges, material options, and connector performance before production begins. Each harness is made to meet the exact conditions it will face in the field.

Engineering and production teams work together to apply proven design principles, follow industry testing standards, and document each step for traceability. This process helps reduce variation and gives OEMs a consistent, dependable product across every order.

From prototype through full-scale production, Kato Cable builds harnesses that perform reliably where failure isn’t an option.

Industries That Depend on Rugged Wire Harness Design

Wire harness design for harsh environments plays a key role in industries where equipment is exposed to heavy use, weather, vibration, and contaminants. Construction, agriculture, defense, and industrial automation all require electrical systems that keep working under pressure. In these settings, a harness failure can stall operations, create safety risks, or damage high-value equipment.

OEMs in these

industries count on reliable performance over long cycles of use. That reliability begins at the design stage and is carried through to material selection, assembly, and testing. Working with a partner who understands the demands of the application helps avoid delays, warranty claims, and system downtime.

Strengthen Performance in Every Condition With Kato Cable

Building a harsh environment wire harness takes more than good materials. It takes experience, process control, and a clear understanding of the conditions the harness will face. Kato Cable brings all of that to the table, along with a team that collaborates directly with OEMs to get every detail right.

If your equipment needs to perform in heat, cold, vibration, or exposure to moisture and chemicals, Kato Cable can help. Request a quote or follow us on LinkedIn and Facebook to

start a conversation about high-performance solutions that match your environment.