Troubleshooting Guide for Cable Assemblies & Wire Harnesses

Share Article:

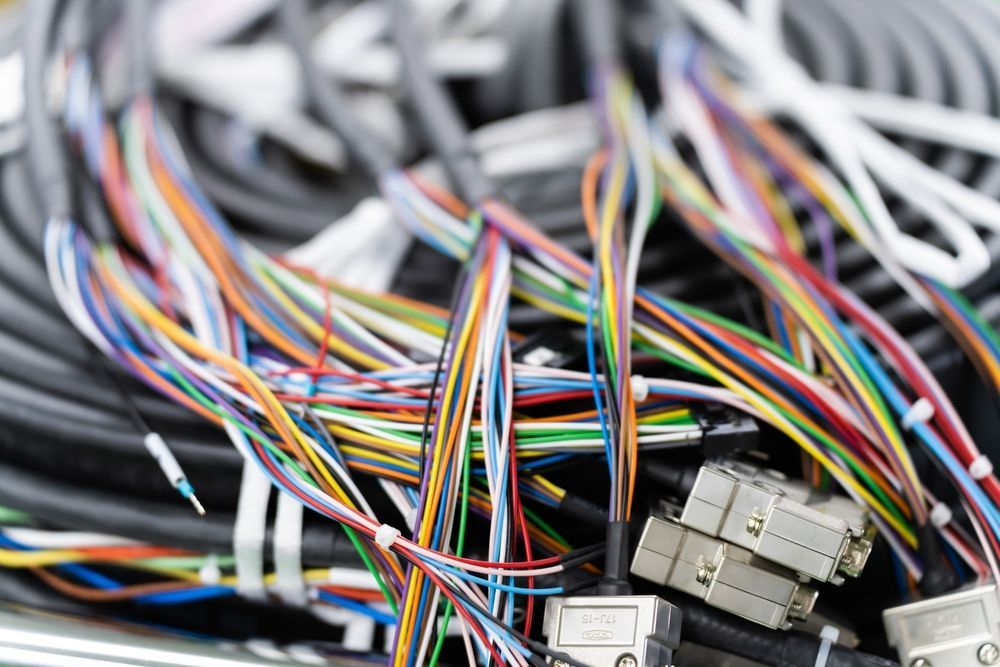

Cable assemblies and wire harnesses play a direct role in how electrical systems perform. They carry power, transmit signals, and connect key components throughout a machine or vehicle. When something goes wrong, the impact often reaches far beyond the wiring itself.

Troubleshooting these assemblies takes more than visual checks or basic continuity tests. It requires an understanding of how the system operates, where weak points typically appear, and how to trace failures back to the source.

For OEMs, cable assembly troubleshooting and wire harness troubleshooting help maintain quality, reduce field failures, and avoid production delays. Getting it right protects both equipment performance and long-term program outcomes.

Why Reliable Assemblies Matter in Critical Equipment

Electrical systems in vehicles, fire trucks, generators, boats, and industrial machinery rely on assemblies that hold up under real-world conditions. Heat, vibration, and exposure to dust, fluids, or chemicals all create stress on wires and connectors. When assemblies are poorly designed or inconsistently manufactured, those stresses can lead to intermittent faults or complete failure.

Reliable assemblies help avoid these disruptions. They maintain stable power delivery, accurate signal transmission, and dependable connections throughout the life of the

equipment. For OEMs, that means fewer warranty claims, less downtime, and stronger confidence in the final product.

Quality at the assembly stage also simplifies service and repair. Logical routing, clear labeling, and consistent workmanship make it easier for technicians to diagnose problems and perform maintenance. The result is better long-term performance and lower total cost of ownership.

Common Problems in Cable Assembly Troubleshooting

Cable assembly troubleshooting often uncovers recurring issues that affect performance and reliability. Some of the most common problems include:

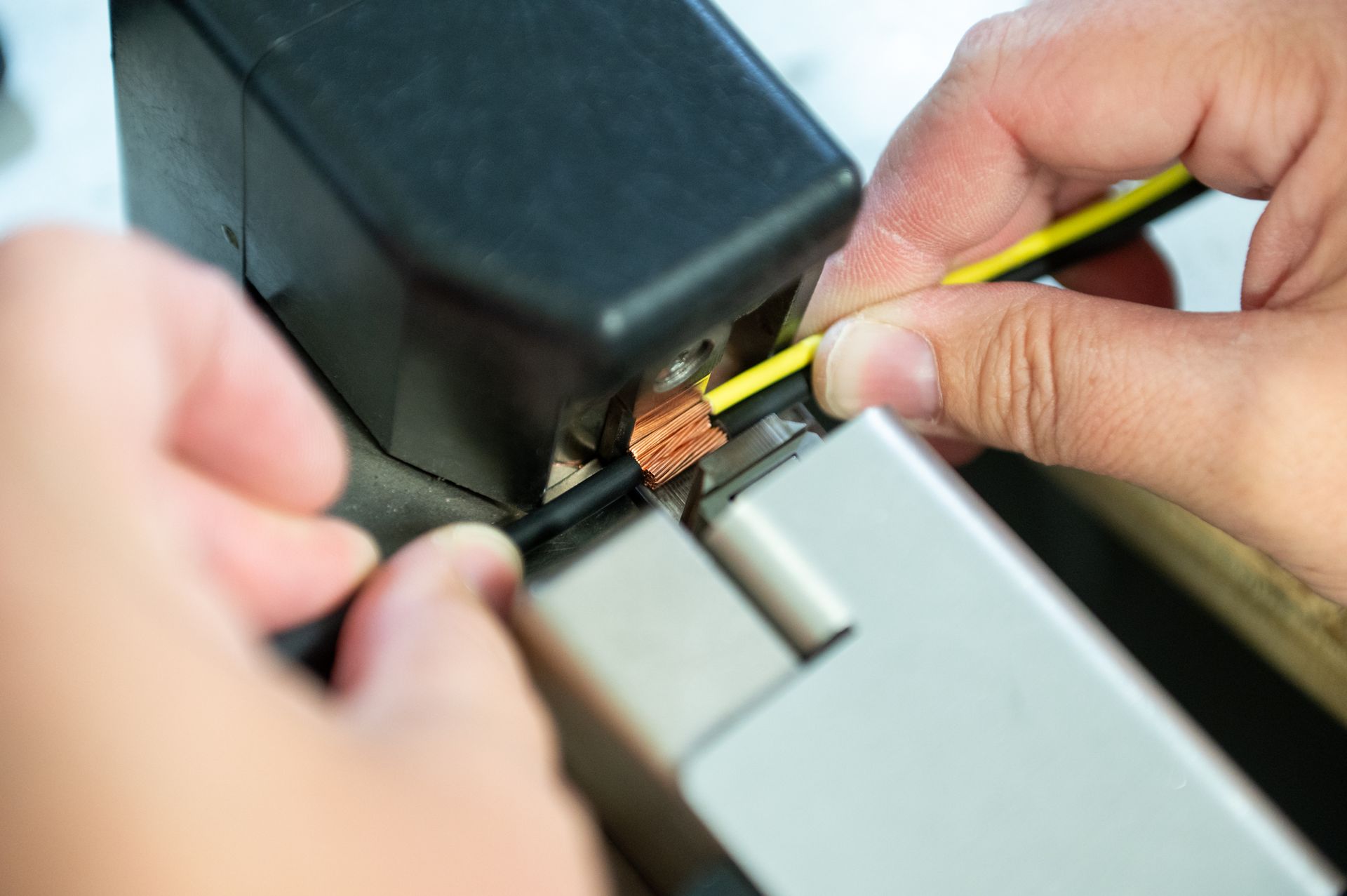

Loose or damaged connectors:

Connectors that aren’t crimped, soldered, or seated properly can create intermittent faults that are difficult to trace.

Abrasion or insulation wear:

Vibration, sharp edges, or repeated movement can wear down insulation, leading to shorts or open circuits.

Incorrect wiring:

Misrouted wires or errors in termination create mismatches that disrupt signals or overload circuits.

Corrosion:

Exposure to moisture, chemicals, or harsh environments can degrade terminals and increase resistance over time.

Improper strain relief: Without proper support, cables and wires can pull against connectors or terminations, causing breaks or weakened joints.

Each of these problems can disrupt performance in the field and lead to costly rework if not identified early.

Wire Harness Troubleshooting Challenges OEMs Face

Wire harnesses often contain dozens or even hundreds of individual wires, each with a specific function. Their complexity makes troubleshooting more difficult than a simple point-to-point cable. When something goes wrong, the issue is rarely obvious. OEM teams often face several challenges in diagnosing harness problems:

Hidden faults inside the harness

Wires may be bundled tightly, making it hard to identify a single damaged conductor or connection without disassembly. This slows down diagnosis and increases labor hours.

Intermittent performance issues

A harness may pass initial testing but fail under vibration, temperature change, or mechanical stress. These intermittent faults are especially frustrating because they are hard to replicate in controlled conditions.

Limited access to equipment

Once installed, harnesses often run behind panels, through conduits, or around tight bends. Reaching them for inspection or testing can require partial disassembly of the equipment, adding time and cost.

Impact on connected systems

A single wiring error can cascade across subsystems, disrupting sensors, controls, or power delivery. This creates a troubleshooting challenge because the symptoms appear in multiple locations, even though the root cause is in one section of the harness.

Inconsistent documentation

When drawings are incomplete or revisions are not updated, technicians waste time tracing wires and verifying terminations. This lack of clarity slows the troubleshooting process and raises the risk of overlooking the real issue.

For OEMs, these challenges turn wire harness troubleshooting into a demanding process that requires accuracy, patience, and coordination across engineering, production, and service teams. Working with a partner that specializes in harness design and diagnostics helps reduce that burden through clear documentation, proven testing methods, and assemblies built for easier service.

How the Right Partner Delivers Reliable Results

Troubleshooting electrical assemblies is often time-sensitive, especially when equipment downtime disrupts production or field operations. The right partner helps reduce that pressure through experience, resources, and proven processes. Instead of treating each problem as an isolated issue, they evaluate the complete system to identify weak points and recurring patterns.

A dependable partner also brings stability to sourcing and documentation. Using approved components, maintaining revision control, and following structured processes minimizes the risk of hidden faults. Thorough testing, such as continuity checks, functional validation, and inspection protocols, confirms that assemblies perform as expected before they reach the OEM.

Clear communication is another factor. When updates are consistent and technical details are well documented, troubleshooting becomes less about guesswork and more about execution.

Kato Cable’s Proven Approach to Troubleshooting

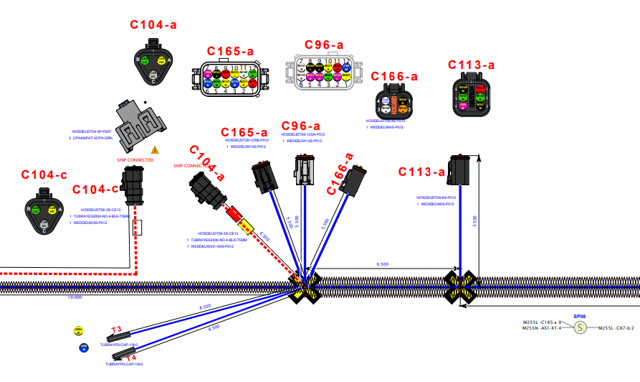

Kato Cable approaches troubleshooting as part of a broader commitment to quality and reliability. Projects begin with a review of technical documentation to confirm wiring diagrams, layouts, and Bills of Materials are accurate. That step reduces the chance of miscommunication and sets a clear direction for production.

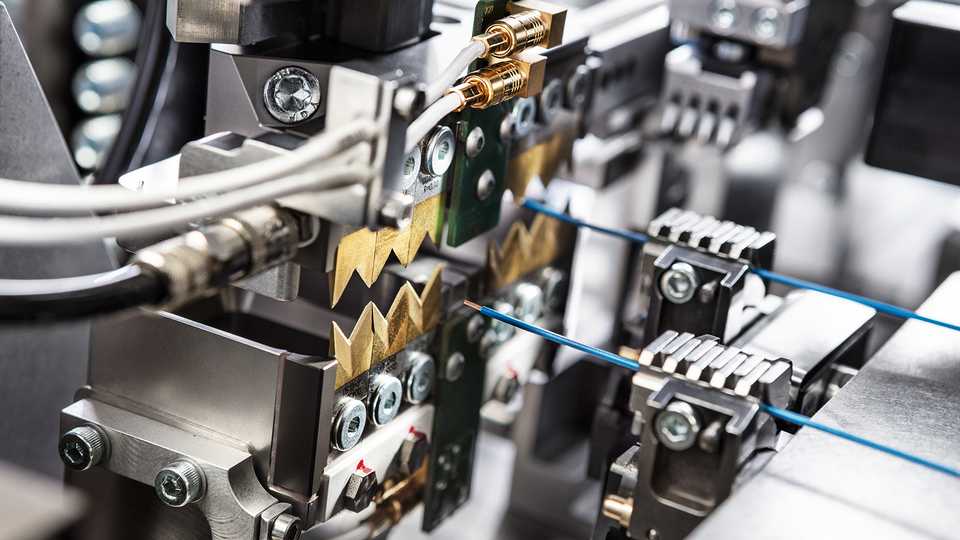

During assembly, technicians follow structured processes that emphasize precision in routing, labeling, and terminations. Any deviations are addressed immediately, supported by inspection points throughout the build. Once a harness or cable assembly is complete, it undergoes continuity testing and functional validation to confirm performance under expected operating conditions.

Troubleshooting continues beyond the production floor. Feedback from OEM partners is tracked and analyzed to refine processes and strengthen future projects. The combination of documentation review, careful assembly, and data-driven improvement allows Kato Cable to deliver assemblies that are dependable and easier to service in the field.

How to Get Started with Kato Cable

Getting started is straightforward. Share your project requirements, and the team will review documentation, provide a detailed quote, and outline timing based on your needs. Communication remains clear at each stage, so expectations match results.

Reach out today

to request a quote and discuss your cable assembly and wire harness troubleshooting needs.