The Benefits of Overmolded Cable Assemblies

Share Article:

In harsh environments where vibration, moisture, or mechanical stress are constant, traditional cable assemblies often struggle to hold up. Overmolded cable assemblies offer a more robust alternative. By encapsulating cable junctions in molded material, they provide protection, improve reliability, and streamline design without compromising performance.

From better strain relief to long-term cost savings, overmolding delivers clear advantages across a range of electrical applications.

What are Overmolded Cable Assemblies?

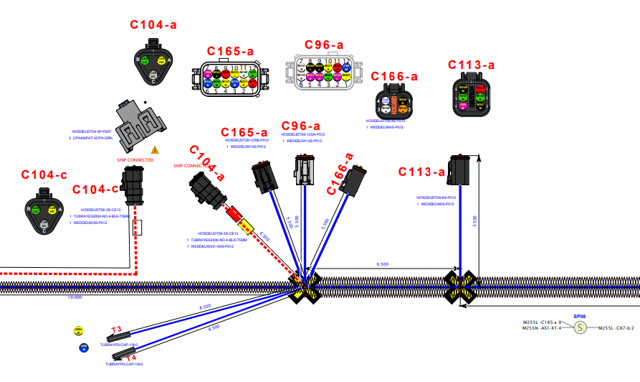

Overmolded cable assemblies are cables that have been encased in molded material, such as thermoplastic or thermoset, to protect critical connection points. The material is applied directly over the junction where wires meet connectors, creating a single, sealed unit.

This process strengthens the assembly, blocks out moisture and debris, and reduces the risk of mechanical failure. Overmolded designs can also be tailored in shape, color, and finish to meet specific application or branding needs.

Overmolded vs. Traditional Cable Assemblies

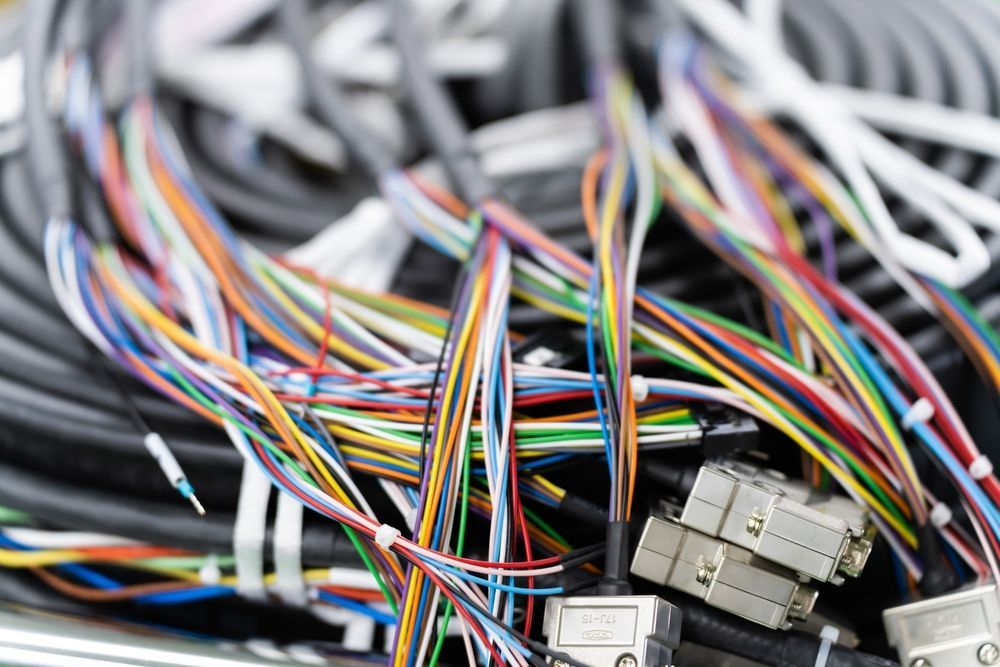

Traditional cable assemblies typically rely on heat shrink, tape, or boots to protect terminations. While these methods offer basic protection, they can wear down over time, especially in environments with constant motion, moisture, or exposure to harsh elements.

Overmolded assemblies offer a more integrated approach. Instead of adding separate protective layers, the molded material becomes part of the structure. This results in a cleaner, more secure connection with fewer points of failure.

The key difference lies in performance. Overmolded cable assemblies maintain their integrity longer, resist environmental stress more effectively, and often simplify installation by reducing the need for additional shielding or support.

Key Benefits of Overmolded Cable Assemblies

Overmolded cable assemblies combine protection, precision, and performance in a single solution. They help reduce failure points, improve handling, and support consistent operation in a wide range of conditions.a

Enhanced Durability and Environmental Protection

Overmolded cable assemblies are engineered to perform in harsh environments where traditional solutions often fall short. The molded material creates a continuous barrier that seals out moisture, dust, chemicals, and other contaminants.

This added protection also helps prevent wear from friction, movement, and impact. As a result, assemblies last longer and maintain their integrity even under repeated stress.

Space and Weight Savings in Complex Assemblies

Overmolded designs help consolidate multiple components into a single, compact unit. Without the need for external boots, clamps, or added hardware, assemblies take up less space and weigh less than traditional alternatives.

This simplified form factor is ideal for tight enclosures and equipment that must stay lightweight. It also allows for cleaner routing and easier integration into densely packed systems.

Improved Strain Relief and Flexibility

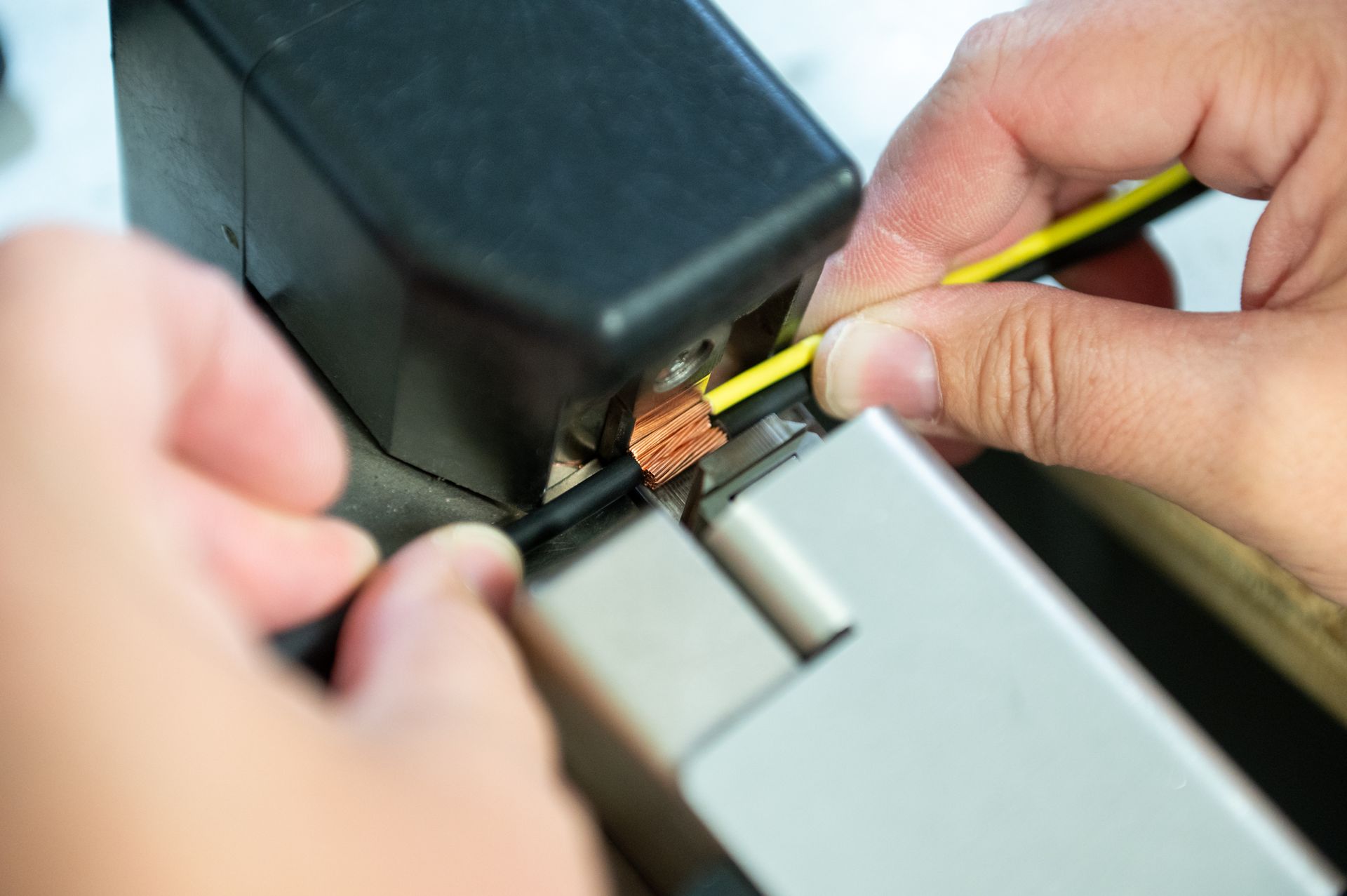

Overmolded cable assemblies provide built-in support where cables are most vulnerable. The molded material reinforces the transition between the cable and connector, helping to absorb movement and minimize mechanical stress.

This design prevents excessive pulling or bending from damaging internal conductors. It also maintains consistent performance in dynamic environments where cables are in motion or under load. The added flexibility reduces fatigue and extends the life of the assembly.

Increased Reliability and Performance

Overmolded cable assemblies maintain stable electrical contact, even in high-vibration or high-use environments. Molded housings secure the components in place, limiting movement that could lead to connection issues.

This construction helps prevent signal loss, electrical noise, and other failures that compromise performance in critical systems.

Streamlined Assembly and Cost Savings Over Time

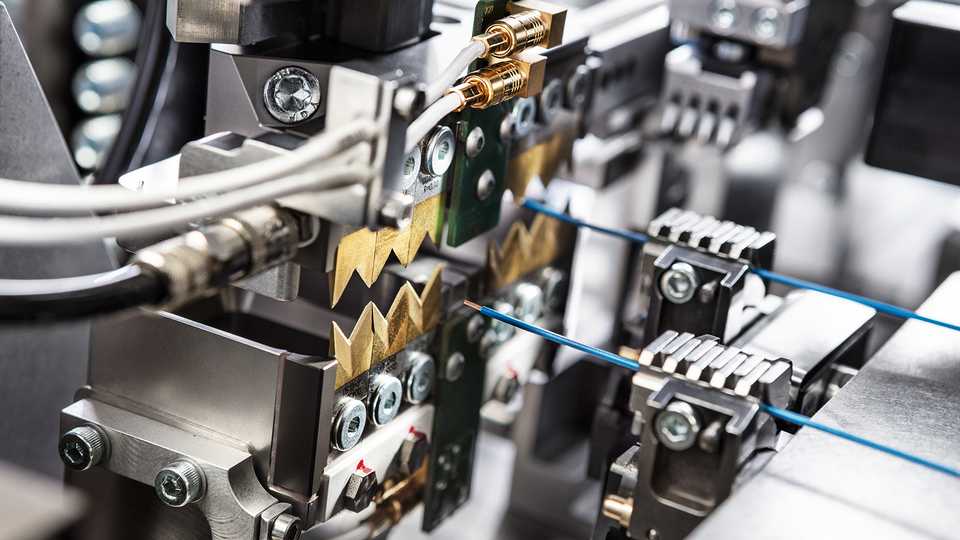

Overmolded cable assemblies simplify the production process. With the connector and strain relief molded into a single unit, installation becomes faster and more efficient.

Fewer components also mean less material handling, lower inventory demands, and fewer chances for assembly errors. These efficiencies contribute to long-term cost savings, improved throughput, and more consistent results across production runs.

Industries That Use Overmolded Assemblies

Overmolded cable assemblies are a strong fit for industries where cables face constant motion, exposure, or wear. Their sealed construction, mechanical reinforcement, and design flexibility make them ideal for environments that demand dependable electrical performance.

Common applications include:

- Automotive: Wiring for sensors, lighting, infotainment, and engine components

- Industrial Equipment: Assemblies for control panels, robotics, and factory automation

- Electronics: Precision connections for instrumentation, testing, and signal processing

- Emergency and Specialty Vehicles: Wiring systems exposed to vibration, weather, and field use

- Marine and Recreation: Moisture-resistant cables for boats, trailers, and outdoor power systems

-

Each of these sectors benefits from the reliability, compact design, and long service life that overmolded solutions provide.

How to Choose an Overmolded Assembly Partner

Finding the right partner for overmolded cable assemblies requires more than just production capacity. Look for a provider with proven engineering expertise, material knowledge, and a track record of supporting high-performance applications.

Kato Cable offers all of the above. With in-house design support, precision tooling, and a collaborative approach, we help OEMs create overmolded solutions that meet tight specs and real-world demands. Our team understands how to balance performance, manufacturability, and long-term reliability.

Trusted Overmolded Assemblies by Kato Cable

At Kato Cable, overmolding is a specialized capability backed by years of hands-on experience. We build cable assemblies that perform reliably in real-world conditions, with attention to both detail and long-term value.

Our team supports OEMs through every stage of development, from initial design input to production-ready solutions. We focus on delivering assemblies that align with your application goals, technical requirements, and project timelines.

Request a quote or connect with us on LinkedIn to start your next project with confidence.