Marine Equipment Wire Harness and Cable Assemblies

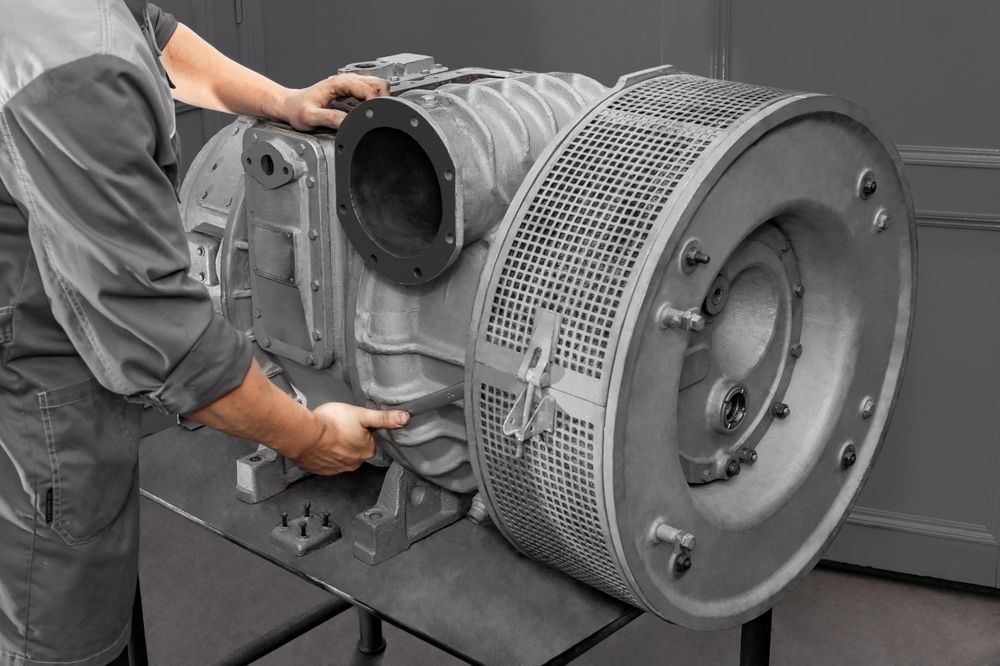

The Challenge of Marine Equipment Electrical Integration

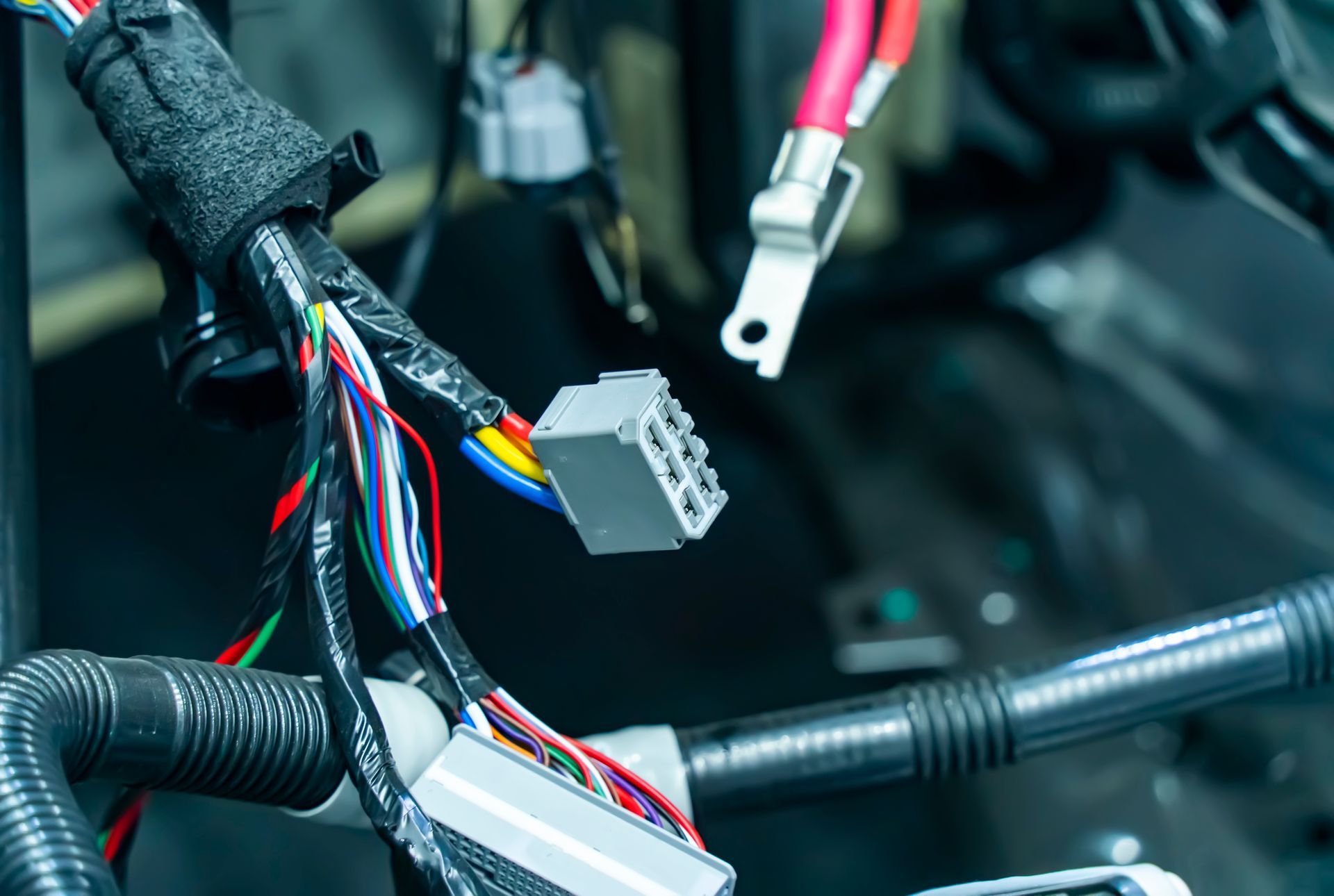

Marine environments present unique challenges for electrical systems. Equipment must operate in conditions where moisture, salt, vibration, and temperature changes are constant threats to reliability. Power distribution, control systems, and communication networks all depend on stable electrical connections to function safely and efficiently on the water.

For OEMs building marine vessels, propulsion systems, and auxiliary equipment, every marine wire harness must be designed to prevent corrosion, withstand harsh conditions, and maintain electrical integrity over time. The consequences of failure in marine applications are costly, which makes performance and durability essential at every level of the system.

Marine Wire Harness and Cable Assembly Solutions

Kato Cable designs and manufactures marine wire harness and cable assembly solutions built for reliable performance in wet, corrosive, and high-vibration environments. We work closely with OEMs to develop custom interconnect systems for vessels, power systems, control panels, and onboard electronics.

Each assembly uses marine-grade materials, sealed connectors, and rugged jacketing to resist water, abrasion, and electrical interference. Marine battery cable assemblies are also built to handle high-power loads with long-term durability. As a marine wire harness manufacturer, Kato Cable delivers the expertise and build quality required for dependable operation in challenging marine conditions.

Marine Equipment Manufacturing Standards and Quality Systems

Marine equipment demands strict adherence to quality standards due to the high-risk environments in which it operates. At Kato Cable, our manufacturing processes are built around precision, consistency, and compliance with industry best practices for marine applications.

Each marine cable assembly undergoes controlled production, thorough inspection, and detailed documentation to maintain full traceability and performance assurance. We use quality-driven workflows to meet the electrical, mechanical, and environmental requirements of marine OEMs. This disciplined approach helps reduce the risk of failure and supports long-term reliability on the water.

Our Products are Proudly Made in the USA

Process Control & Engineering Control Services

Process Control

Precision and consistency are at the heart of every custom cable solution. Our Process Control strategies ensure each assembly meets exact specifications, from initial concept to final production. Through rigorous quality checks, standardized procedures, and real-time monitoring, we optimize efficiency while maintaining the highest level of reliability.

Engineering Control

From concept to completion, Engineering Control ensures every design is optimized for functionality, manufacturability, and long-term performance. Our expert team evaluates form, fit, and function, applies industry best practices and testing protocols, and leverages innovative solutions to deliver high-quality and cost-effective cable and harness assemblies.

Your Industry, Our Vision

The Kato Cable Advantage

The Kato Cable Advantage is a holistic approach to looking at the value that you bring to your customers, employees and community. Our customers relate directly to our responsiveness and engineering value, to the investments that we have made into efficiencies and automation, and to the key metrics of industry leading Quality and On Time Delivery. Our employees relate to a sense of inclusion, an appreciation and value to feedback, and the philosophy of making improvements every day. Our community relates to our growth and volunteerism and leadership that we strive for in our region. Together these attributes and values truly deliver the Kato Cable Advantage!

Quality & Reliability

Delivering precision-engineered wire harnesses, cable assemblies, and electro-mechanical assemblies that meet the highest industry standards.

Innovation

Continuously improving processes and technologies to provide cutting-edge solutions for diverse industries.

Customer Commitment

Building strong partnerships through collaboration, responsiveness, and tailored solutions.

Why OEMs Partner With Kato Cable for Marine Equipment

Marine OEMs partner with Kato Cable for dependable solutions and hands-on support throughout the product lifecycle. Our team understands the unique electrical challenges of marine environments and works closely with customers to deliver assemblies that perform under pressure.

We provide guidance during design, recommend the right materials for harsh conditions, and maintain tight control over production quality. As a marine wire harness manufacturer, we focus on delivering reliable products backed by responsive service and deep technical knowledge. Customers trust Kato Cable to help them build safer, more efficient marine systems.

Our Certifications

Stay Connected with our Blog

Industry Template Contact Us

We will get back to you as soon as possible.

Oops, there was an error sending your message. Please try again later.

Request a Quote for Marine Equipment Cable Assemblies

Reliable electrical systems are essential for safe and efficient marine operations. Kato Cable provides custom marine cable assemblies and wire harnesses engineered for high performance in the harshest conditions.

If you're looking for a partner who understands the technical demands of marine equipment and meets them with precision and consistency, we're ready to help. Request a quote today and move forward with confidence in your interconnect solution.