Different Types of Cable Shielding Explained

Share Article:

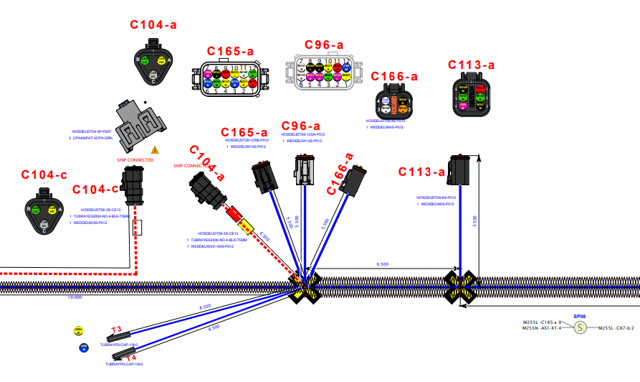

Electrical noise is a constant threat in complex assemblies. Motors, sensors, power lines, and wireless devices all generate electromagnetic interference that can disrupt signal quality. Cable shielding plays a key role in keeping communication lines stable, especially in high-noise environments like manufacturing floors, test labs, and mobile equipment.

OEMs that rely on precise data transfer and uninterrupted signals need shielding options that match both electrical demands and mechanical conditions. Understanding the differences between shielding types helps engineers make informed choices during the design and procurement process.

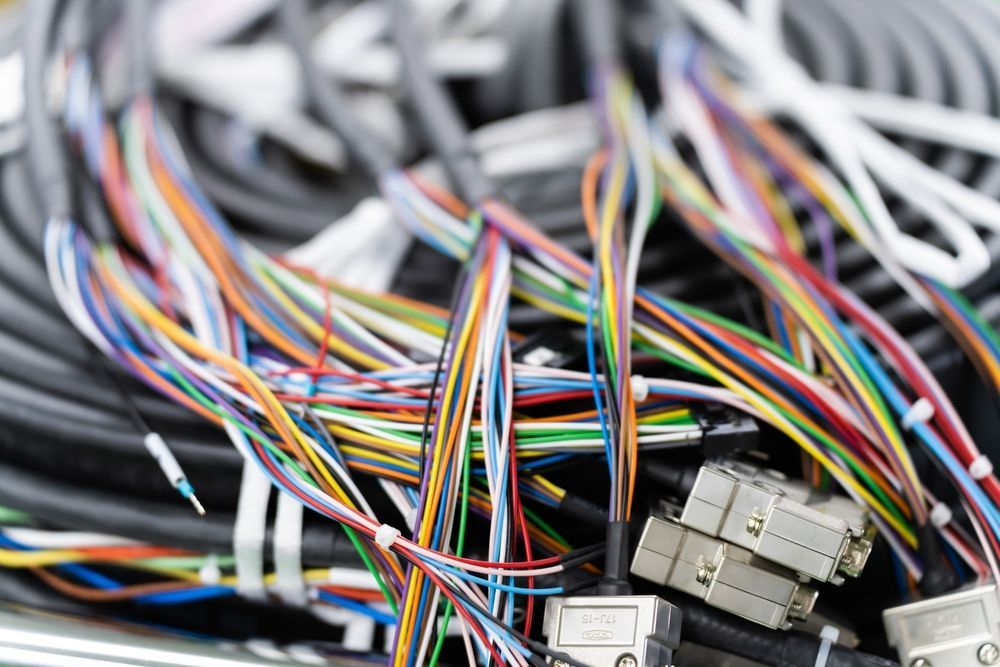

What Is Cable Shielding?

Cable shielding refers to the conductive barrier wrapped around signal-carrying conductors inside a cable. Its purpose is to block external electromagnetic interference (EMI) from reaching the inner wires and to prevent the cable itself from radiating noise that could affect nearby circuits.

This barrier can be made from metal foil, braided wire, conductive tape, or a combination of materials. The design, coverage, and grounding of the shield all influence how well it performs. Some shielding types excel at blocking high-frequency noise, while others are better at protecting against low-frequency interference or physical wear.

Shielding becomes especially important in environments where multiple systems operate side by side. It keeps signals clean, consistent, and isolated from surrounding noise sources.

Why Shielding Matters in OEM Assemblies

In tightly packed assemblies, electrical noise becomes a real design challenge. Shielding helps prevent outside interference from distorting signals or causing devices to misfire. Without it, systems that rely on clean data or stable communication often experience unpredictable behavior.

Sensitive components placed near power lines, motor drives, or switching equipment can pick up stray signals. That noise travels through unprotected wiring and disrupts functions like timing, feedback, or control logic.

Shielding blocks that interference at the source. It also helps maintain signal integrity across longer runs or in electrically noisy environments. In OEM builds, it’s a practical tool for reducing downtime, limiting rework, and delivering consistent performance in the field.

Common Types of Cable Shielding

Shielding comes in several forms, each designed to handle specific noise levels, frequencies, and mechanical demands. The most common options include foil, braid, tape, and spiral designs. Some cables use a combination for added protection.

Foil Shielding

Foil shielding uses a thin layer of metal, usually aluminum, bonded to a polyester or similar backing. This creates a lightweight wrap that offers full coverage around the conductors.

It’s effective at blocking high-frequency interference and is commonly used in data cables, audio lines, and low-voltage signal applications. Because of its flexibility and low profile, foil shielding fits well in tight spaces or bundles with multiple conductors.

However, it’s less durable under mechanical stress and doesn't perform as well in environments with frequent bending or vibration. For static installations or cables with minimal movement, foil shielding provides a compact and cost-effective solution.

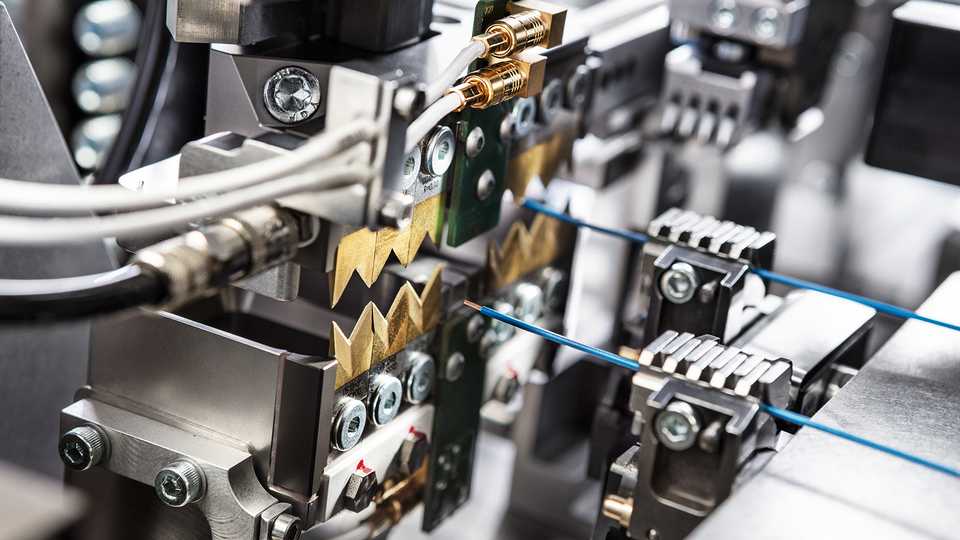

Braided Shielding

Braided shielding uses woven strands of copper or tinned copper to form a mesh around the conductors. This structure holds up well under motion, making it suitable for cables routed through moving equipment or exposed to vibration.

The braid helps block low to mid-frequency interference and creates a reliable grounding path. It also adds physical reinforcement, protecting internal conductors from abrasion during handling or flexing.

While the weave doesn’t fully block high-frequency noise, it performs well in electrical systems where strength and durability matter more than total coverage. Many OEMs rely on braided shielding in applications that combine mechanical stress with electrical sensitivity.

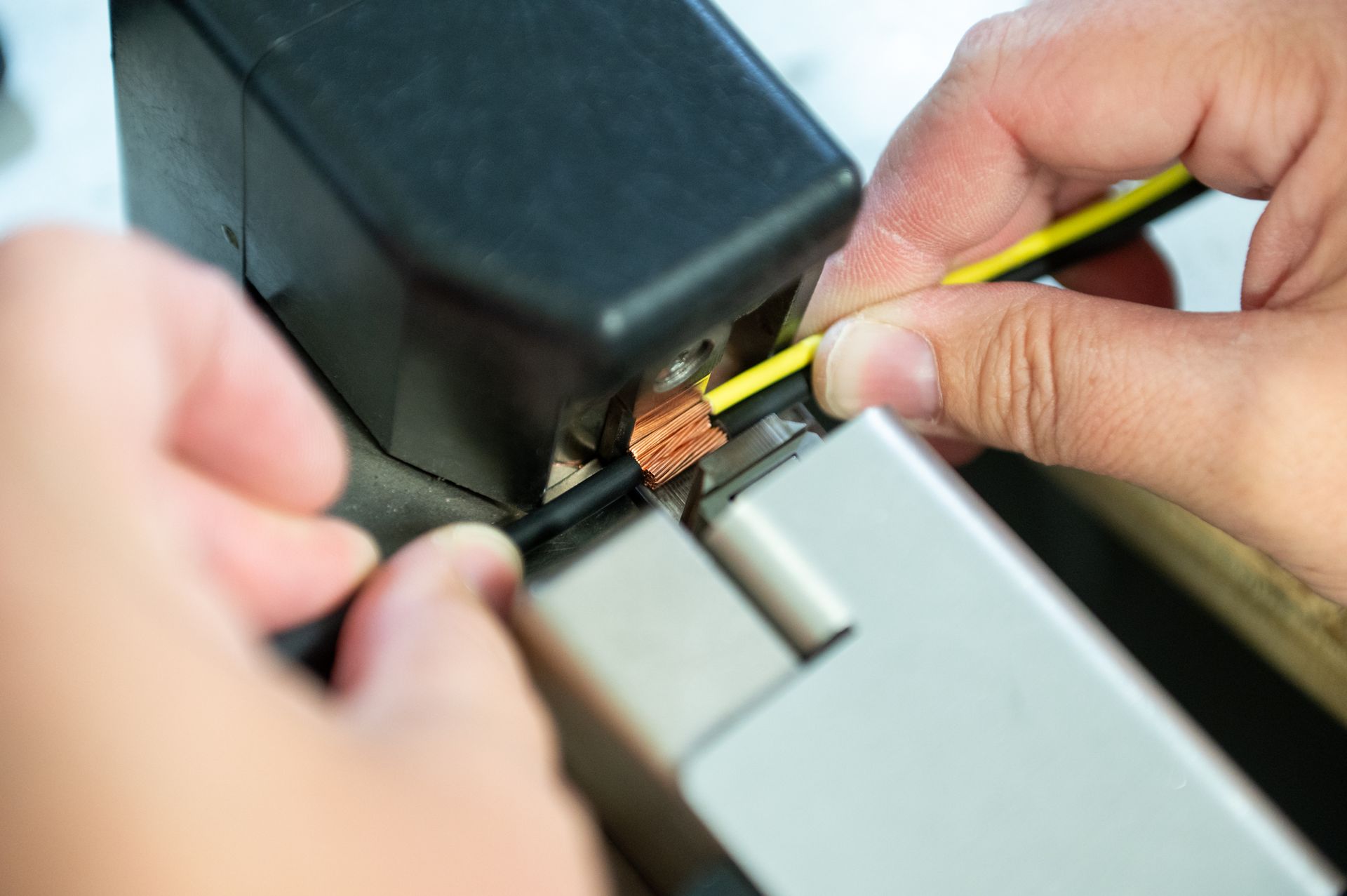

Tape Shielding

Tape shielding uses conductive material, such as aluminum or copper, applied in overlapping wraps around the cable core. The spiral overlap creates a flexible barrier that conforms easily to bends and irregular shapes.

Unlike solid foil, tape can stretch slightly, making it a practical choice for cables that need to flex but still maintain consistent coverage. It handles both low- and high-frequency interference reasonably well and is often combined with other shielding types to improve performance.

This type works well in applications that demand flexibility without sacrificing signal protection or ease of installation.

Spiral & Hybrid Shielding Options

Spiral shielding wraps individual wires in a loose, helical pattern around the cable core. This design increases flexibility and works well in assemblies that require frequent bending, such as audio cords, handheld tools, or medical devices. It’s easy to terminate and lightweight, but it doesn’t provide full coverage, which limits its ability to block high-frequency noise.

Hybrid shielding combines two or more methods to address both electrical and mechanical requirements. A common pairing is foil for high-frequency protection layered beneath a braid for strength and grounding. Some variations include a combination of tape and spiral wrap for added flexibility in tight spaces.

These blends are often used in environments that demand both signal integrity and physical resilience. They support applications where a single type of shielding would fall short.

Are Braided Cables Better?

Braided cables perform well in systems where movement, grounding, and durability are constant concerns. The woven design resists tearing and holds up to repeated flexing, which makes it a reliable choice for industrial equipment, robotics, and mobile assemblies.

That strength comes at a tradeoff. Braided shielding doesn’t block high-frequency interference as effectively as foil. In high-speed data or sensitive communication lines, full-coverage foil or hybrid shielding may be a better fit.

Choosing braided cable depends on the application. If the cable moves often, needs strong grounding, or faces physical wear, braid tends to hold up better over time. In static installations with high-frequency noise, other shielding types may perform better.

Choosing the Right Shield for Your Application

No single shielding method fits every design. Each cable must be matched to the electrical environment, movement requirements, and installation conditions it will face. In systems with minimal motion but dense electronics, a thin, fully wrapped layer like foil can reduce interference without adding bulk.

Where the cable moves often or runs near motors and contactors, a mesh-style barrier adds physical stability and electrical continuity. For designs where both flexibility and noise reduction matter, a layered approach balances protection and handling.

Why OEMs Trust Kato Cable for Shielded Solutions

Kato Cable supports OEMs with shielded assemblies built for demanding environments. Each project is developed around specific electrical and mechanical needs, using materials and methods that hold up in the field.

The team brings deep experience across control systems, motion applications, and signal routing. That knowledge helps customers avoid common pitfalls and stay on schedule.

For shielded solutions that meet both technical and production goals, request a quote or connect with Kato Cable on LinkedIn.