The Benefits of Ultrasonic Welding Over Splicing

Share Article:

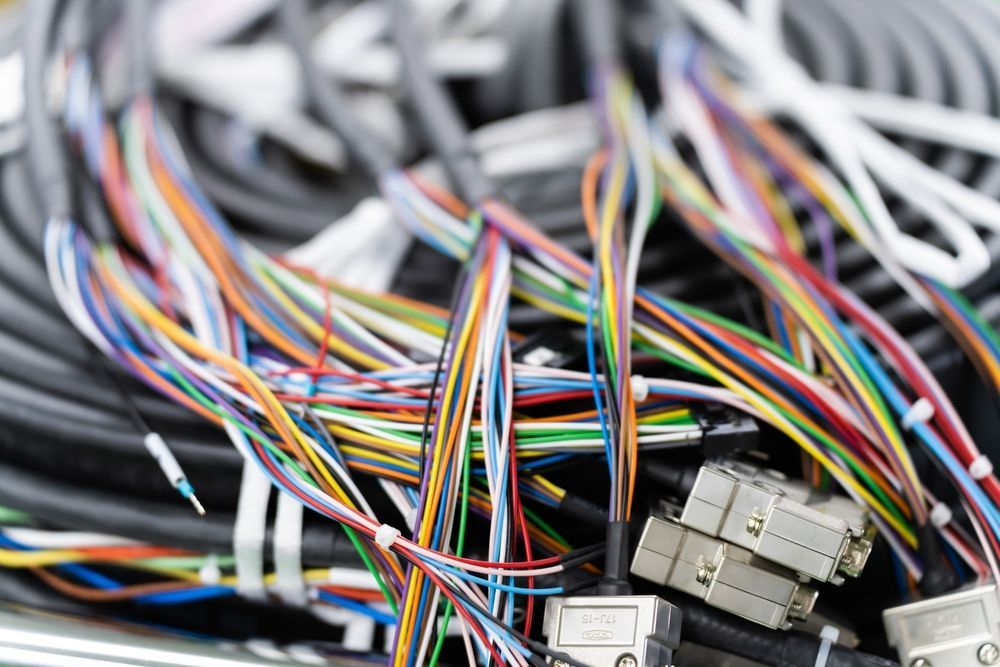

In wire harness manufacturing, how conductors are joined has a direct impact on performance, reliability, and throughput. While splicing has long been used for electrical connections, ultrasonic welding is gaining traction across industries that require consistent, high-integrity bonds.

Choosing the right method matters, especially for OEMs producing at scale or working in mission-critical environments. Understanding the differences helps align production goals with the most efficient and durable bonding process.

What Is Ultrasonic Welding?

Ultrasonic welding bonds wires through vibration and pressure, not external heat or solder. It creates a solid-state connection that delivers strength, conductivity, and repeatability for production-scale harnesses.

How It Works in Wire Harness Manufacturing

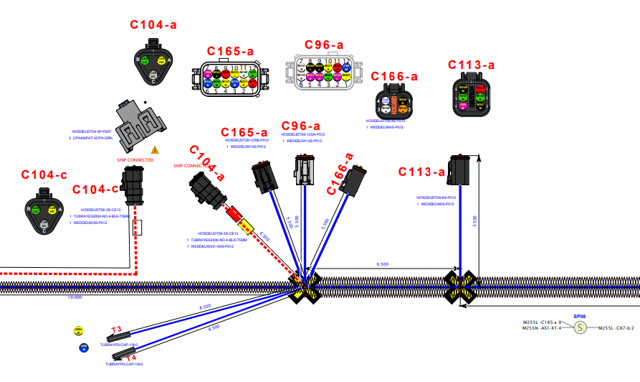

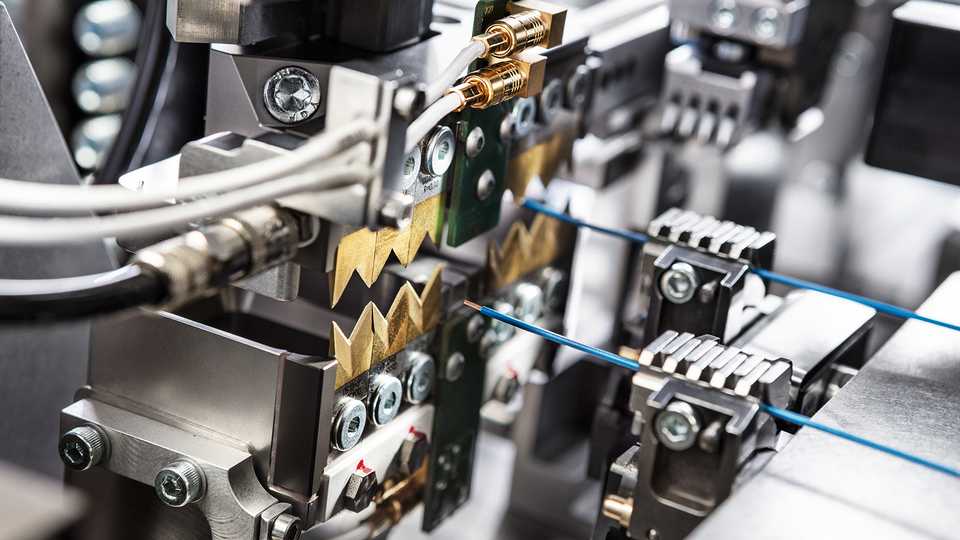

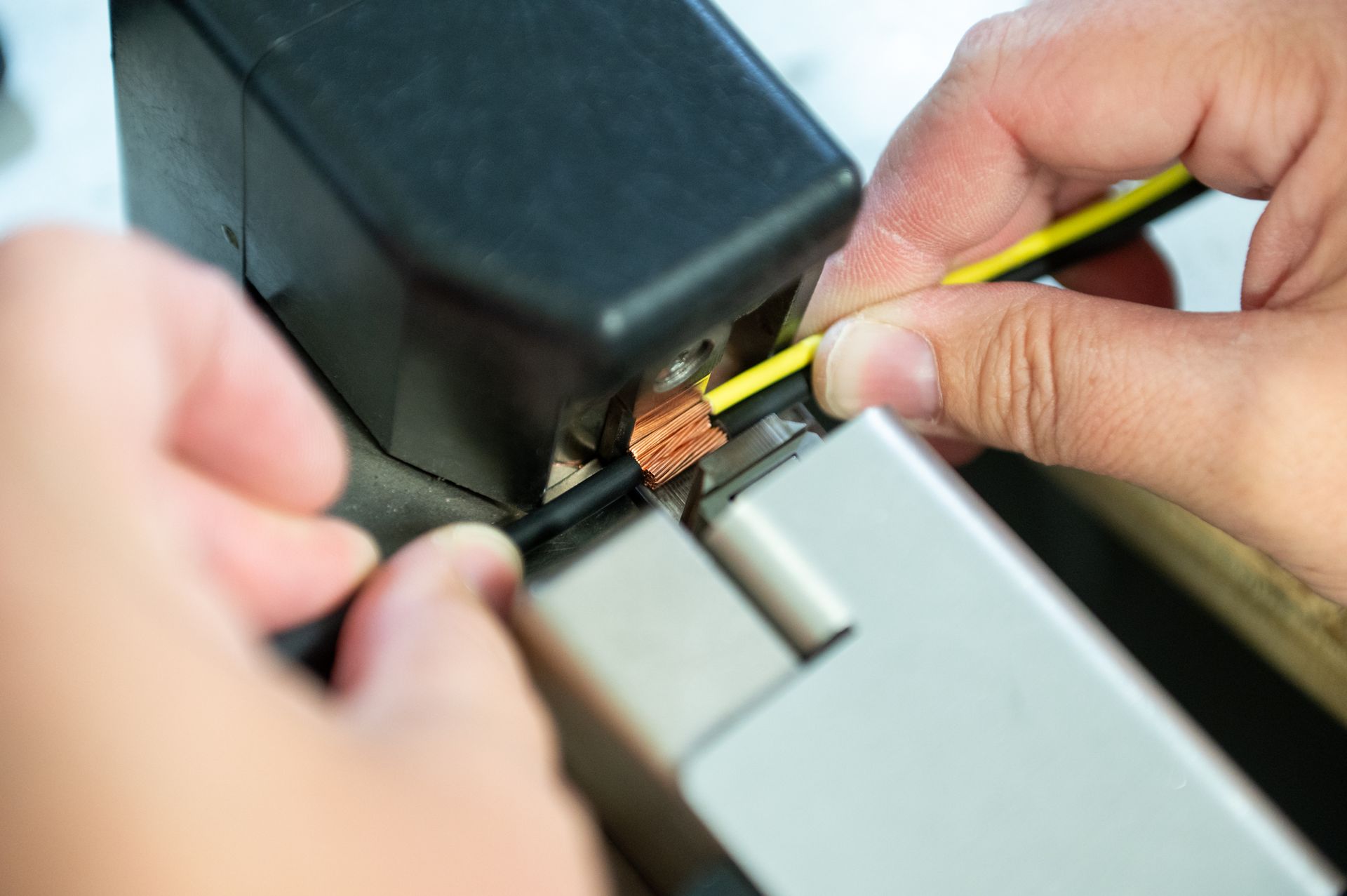

Wires are stripped and positioned in a precision die. Once clamped, the machine applies high-frequency vibrations under pressure. This energy disrupts the copper at the contact point, allowing the strands to fuse at the molecular level.

The result is a clean, uniform bond without melting or added material. Once welded, heat shrink tubing is applied to insulate and seal the connection. At Kato Cable, adhesive-lined sleeves from Raychem and Dunbar are used to protect against moisture, dust, and movement.

Wire Compatibility and Material Needs

Ultrasonic welding works best with stranded copper wire in small to medium gauge sizes. The process relies on uniform pressure and molecular bonding, so the wires must be clean, oxide-free, and stripped to the proper length.

Because the weld forms without filler or solder, no additional conductive material is required. Only the wires and a heat-shrink sleeve are needed to complete the connection. This simplifies sourcing and reduces variability in connection quality. For multi-wire welds, consistent strand construction helps maintain a balanced, repeatable bond.

What Is Wire Splicing and Butt Splicing?

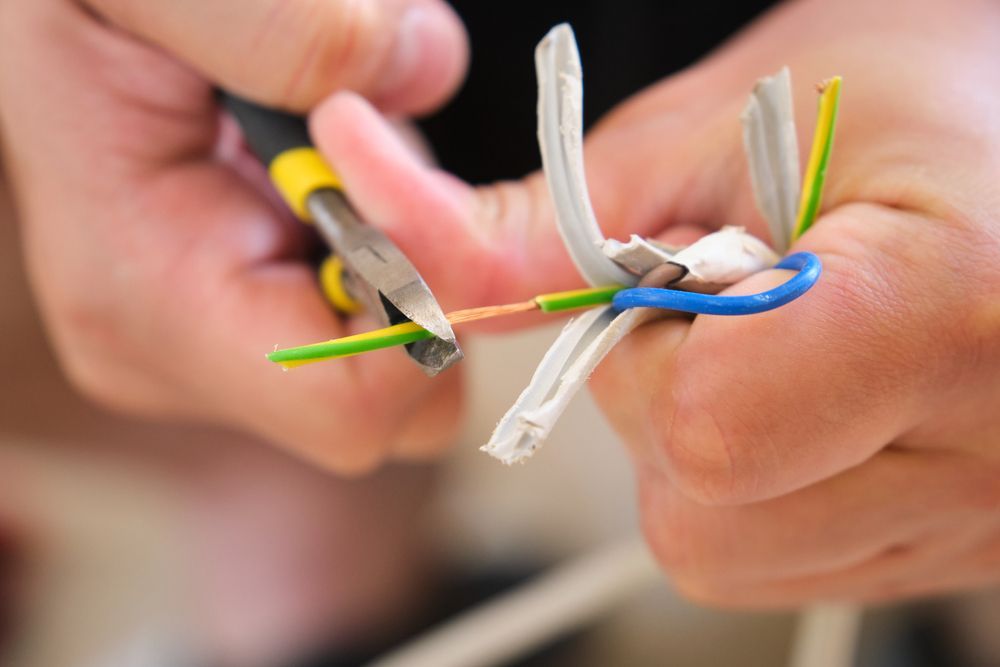

Wire splicing joins two or more conductors using a mechanical or soldered connection. In most harness applications, this is done using a butt splice. The stripped ends of the wires are inserted into a connector and secured through crimping or soldering.

Afterward, the connection is insulated using tape, tubing, or heat shrink. The strength and conductivity of the splice depend on proper tool use, material fit, and operator technique.

Common Methods and Limitations

Crimping

- Quick and widely used in the field or low-volume settings

- Requires a crimp connector and a handheld or benchtop crimper

- Connection strength depends on tool pressure and crimp alignment

- Inconsistent crimps can lead to weak electrical or mechanical performance

Soldering

- Used when a permanent splice is needed

- Involves heating the connection and applying solder

- Can be time-consuming and sensitive to technique

- Solder joints may crack or fail under vibration

Both methods are manual, which increases variability. They also depend on multiple steps to complete and may not scale well in high-volume builds.

Ultrasonic Welding vs Splicing: What Sets Them Apart

Connection quality depends heavily on the bonding method. Ultrasonic welding and traditional splicing each produce physical joins, but the materials, tools, and results involved lead to very different performance outcomes.

Bonding Method and Heat Use

Ultrasonic welding forms a metallurgical bond by applying high-frequency vibrations and pressure. The process generates localized heat through friction, which causes the copper strands to fuse without melting. No filler material or open flame is involved.

In contrast, splicing relies on either mechanical force or external heat. Crimping compresses the wires into a connector, while soldering melts a filler metal to hold the conductors together. These methods do not alter the internal structure of the copper and require more steps to complete and seal.

Electrical and Mechanical Performance

Ultrasonic welding produces a low-resistance, gas-tight connection that maintains consistent conductivity across all welded joints. Because the bond is uniform and repeatable, it performs well in circuits sensitive to voltage drop or signal interference.

The mechanical strength of the weld resists vibration, thermal cycling, and pull forces, making it dependable in high-motion or mission-critical environments.

Spliced connections vary more in quality. Crimped or soldered joints can introduce resistance if not done correctly, and mechanical strength depends on the integrity of the crimp or solder bond. Over time, these joints are more likely to degrade under stress or movement.

Cost, Labor, and Production Efficiency

Ultrasonic welding requires a higher initial investment in equipment but reduces labor time and training needs. Once set up, the process is fast, repeatable, and easy to automate. This makes it a strong fit for high-volume production where consistency and speed are priorities.

Splicing involves low-cost tools and materials but relies heavily on manual labor. Each splice takes more time and depends on operator skill. Over many units, this can lead to longer build cycles and more variation between assemblies.

When to Use Ultrasonic Welding vs Splicing

Ultrasonic welding is suited for consistent, high-volume production. Splicing is more common in low-volume builds, repairs, or flexible setups. The right choice depends on performance requirements and how the wire assemblies will be used.

Best Applications by Volume and Environment

High-volume manufacturing environments benefit from ultrasonic welding due to its speed, consistency, and durability. Applications like engine compartments, control modules, and mission-critical systems often call for this type of connection.

Splicing tends to show up in smaller batches or repair work where flexibility and quick turnaround are key. It’s a better fit for non-critical systems or settings where long-term exposure to vibration and heat isn’t a concern.

Partner With Kato Cable for Precision Welded Assemblies

Kato Cable delivers wire harness solutions built for performance, consistency, and production efficiency. Our ultrasonic welding capabilities are designed to meet the needs of OEMs that demand low-resistance connections and long-term reliability across every unit.

We use high-precision equipment and adhesive-lined heat shrink from trusted suppliers like Raychem and Dunbar to seal and protect each welded joint. Every connection is produced with care and tested to meet your application’s electrical and mechanical requirements.

If you're looking for a manufacturing partner who can scale quality alongside volume, we’re ready to help.

Request a quote or follow us on LinkedIn and Facebook to learn more.